Why Copper Tubes Are Used in Fin-and-Tube Coils

Introduction

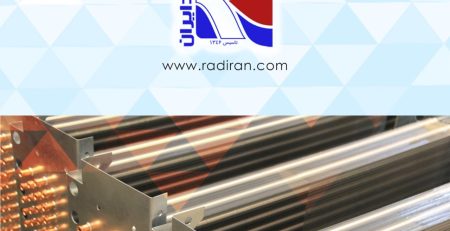

The choice of tube material in fin-and-tube coils strongly affects performance, durability, and life-cycle cost in HVAC, chillers, boilers, and heat exchangers. Copper (Cu) is one of the most common choices. Below are technical, organized reasons why copper tubes are preferred.

1. High Thermal Conductivity

• Copper has very high thermal conductivity compared with many common metals (e.g., carbon steel).

• High conductivity enables fast, efficient heat transfer between the fluid inside the tube and the external fins, improving overall coil heat-transfer effectiveness.

• This property can reduce required coil length and surface area for a given thermal duty.

2. Formability and Fabrication Ease

• Copper is ductile and easily formed; it allows manufacturing tubes in various diameters and wall thicknesses, bending, cutting, and reliable joining.

• Copper readily accepts brazing and soldering, which is important for making leak-tight joints between tubes, fins, and manifolds in coil fabrication.

3. Corrosion Resistance and Service Life

• Copper exhibits good resistance to many common corrosion mechanisms encountered in HVAC coils, providing satisfactory durability in typical ambient and moist-air conditions.

• Protective coatings, copper alloys (e.g., bronze or brass), and appropriate design practices can further extend service life.

4. Antimicrobial Properties and Hygiene

• Copper has natural antimicrobial characteristics. This can be a hygienic advantage in applications where airflow or condensate could support microbial growth (e.g., hospital AHUs or other sensitive environments).

5. Compatibility with Refrigerants and Heat Transfer Fluids

• Copper is chemically compatible with most common refrigerants and heat-transfer fluids and does not typically react adversely.

• Its ability to be joined into low-leakage assemblies (brazed or soldered) supports operational integrity and reduces environmental risk from refrigerant leaks.

6. Economic Considerations and Maintainability

• Although copper raw material cost can be higher than some alternatives, its high thermal performance, longevity, and ease of repair (local tube replacement, brazing repairs) reduce overall life-cycle cost.

• Wide availability, established manufacturing standards (e.g., ASTM), and a mature supply chain lower procurement risk.

Conclusion

In summary, copper tube use in fin-and-tube coils is driven by high thermal conductivity, good formability and joining ability, resistance to corrosion, antimicrobial benefits, compatibility with refrigerants, and favorable life-cycle economics. This combination of properties makes copper a practical and widely adopted material for fin-and-tube heat exchangers.