Common installation errors in heat exchangers

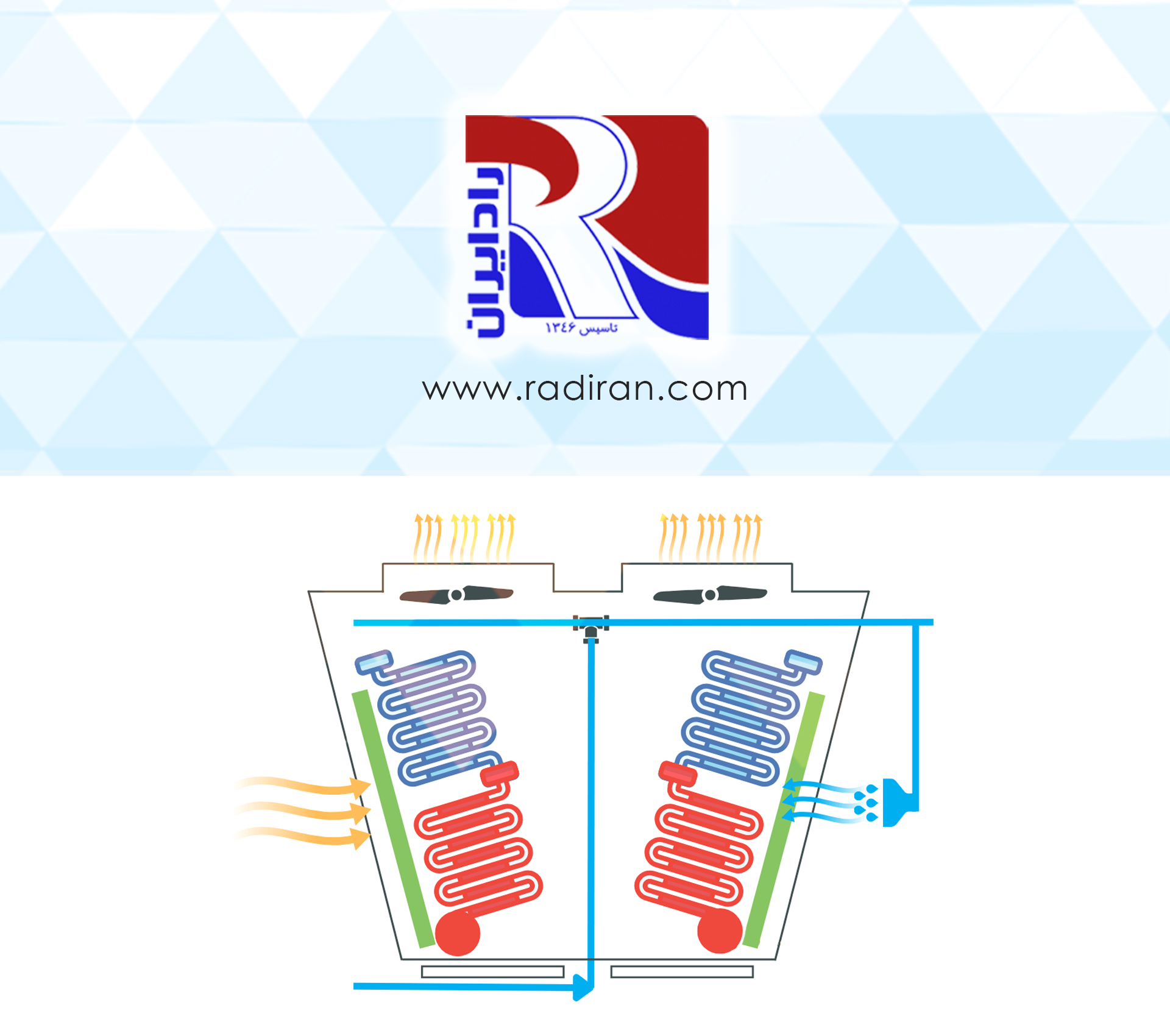

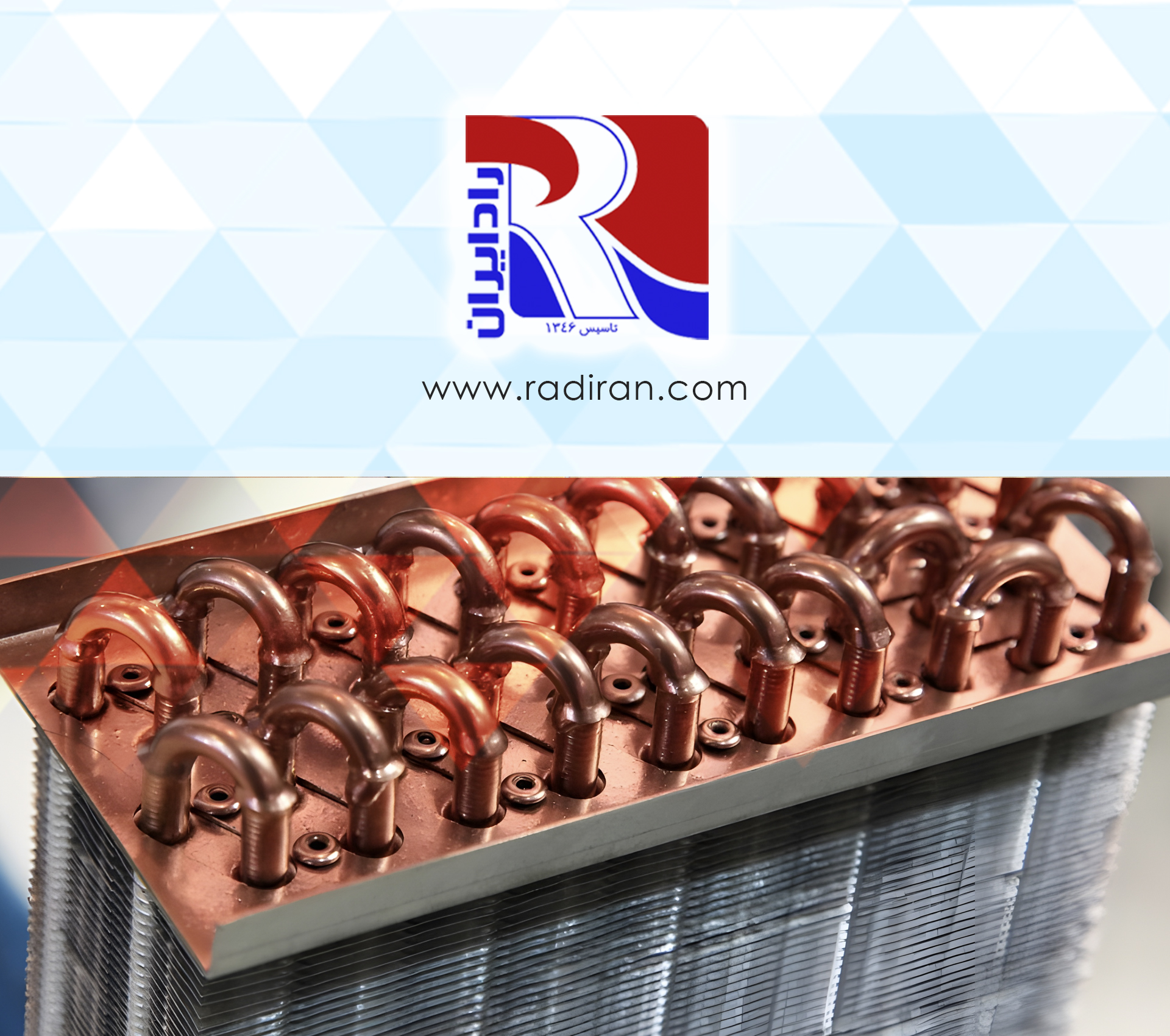

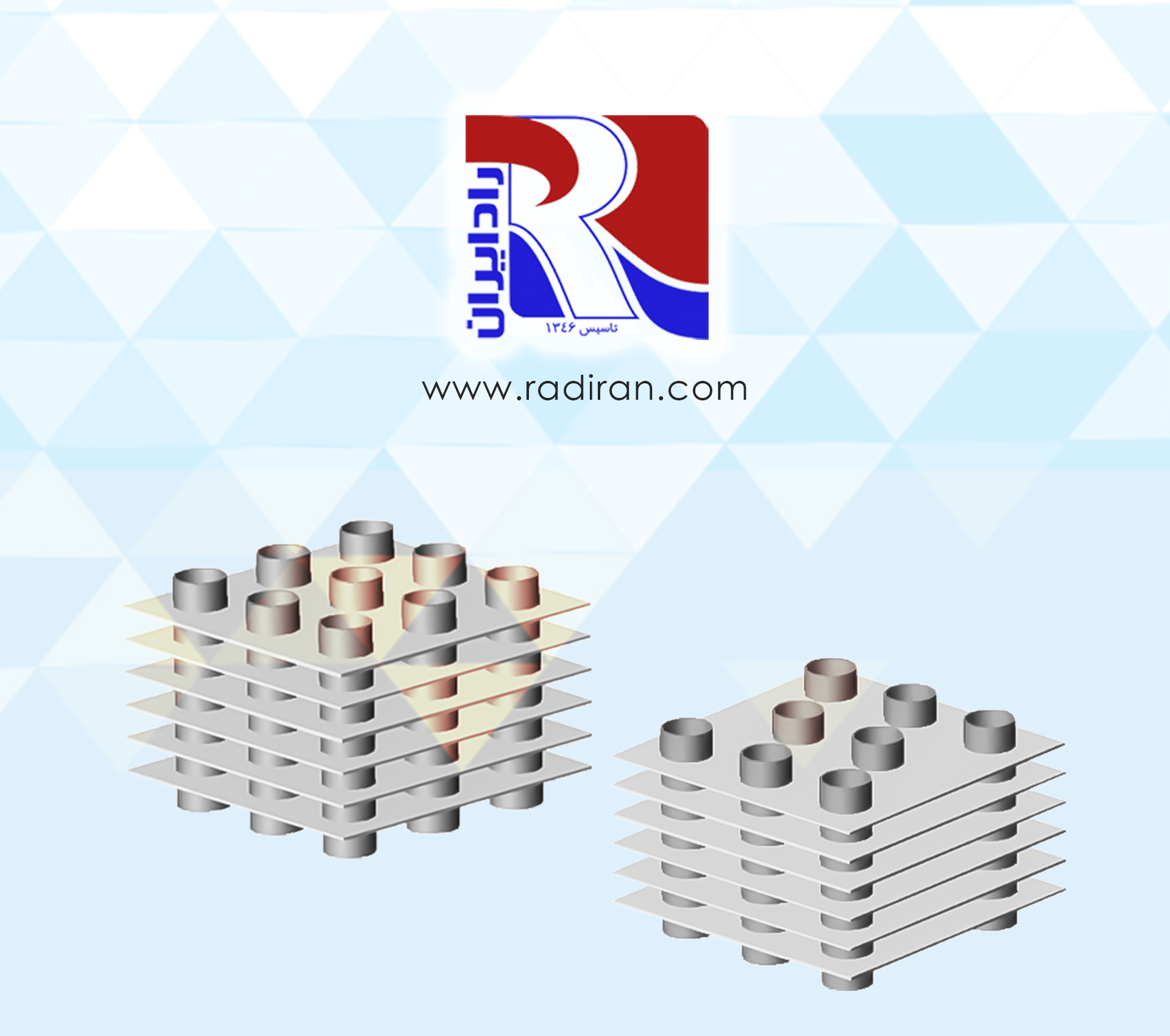

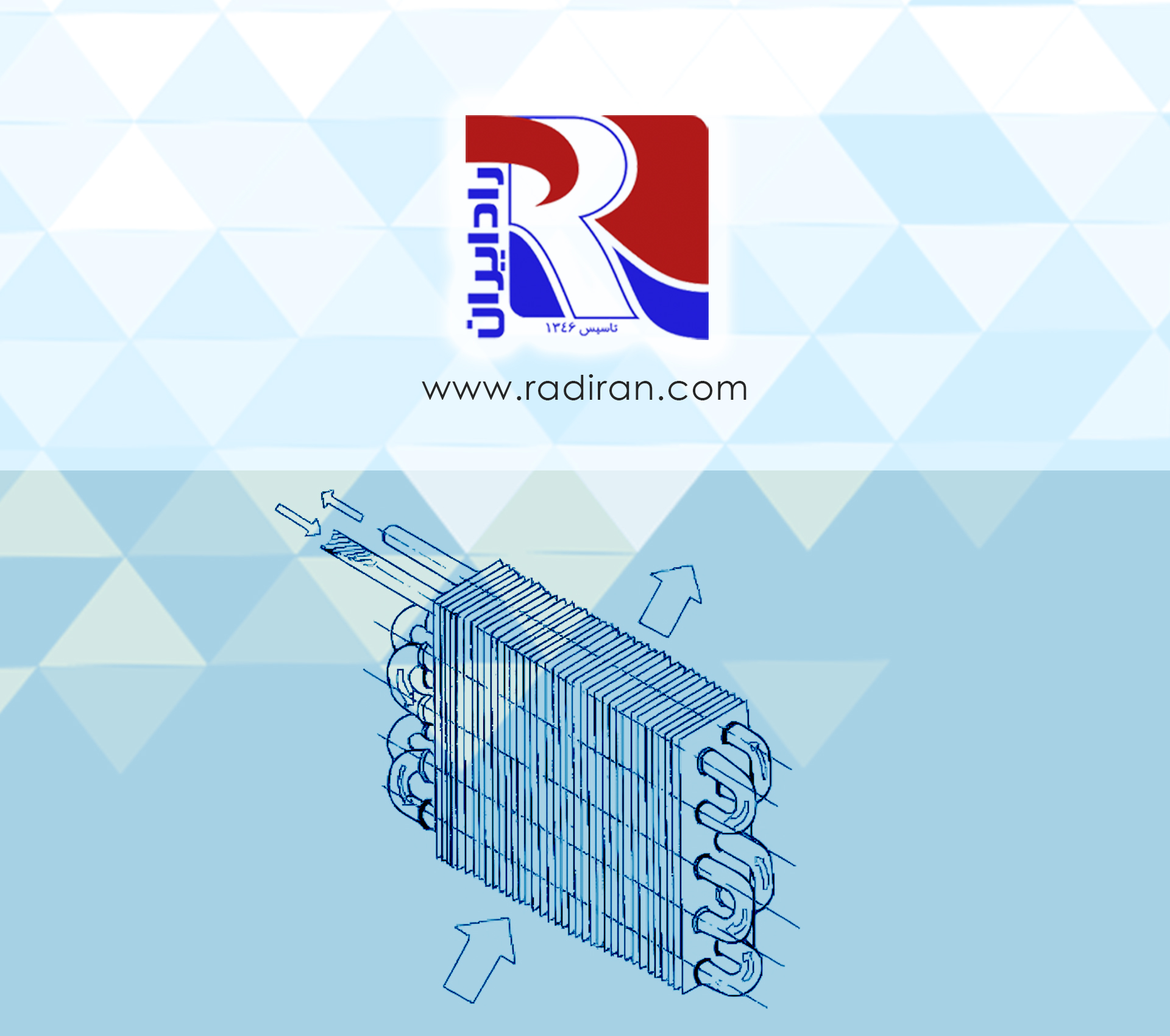

Common Installation Mistakes for Finned-Tube Coils Used as Water Heat Exchangers (Evaporator or Condenser) Installing finned-tube coils in HVAC and refrigeration systems is common, but installation mistakes can severely degrade performance and reduce service life. Below are the most frequent errors and their technical consequences: 1. Incorrect orientation and flow direction • Mistake: Installing the coil so that the air or fluid flow direction contradicts the manufacturer's design (e.g., reversed tube routing or fan orientation). • Consequence: Reduced heat transfer, localized hot/cold spots, increased...