Service Valves in Refrigeration Systems

systems and explains the role of each in the proper functioning of the system:

- Hand Valve:

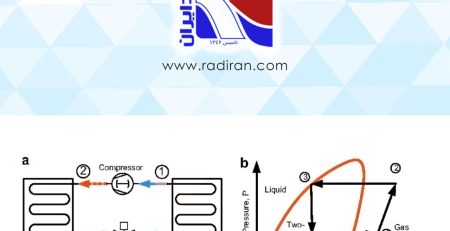

Hand valves are used for manual control of refrigerant flow in the piping lines. They allow manual opening or closing of the flow and are used during system maintenance and repair. - Suction Service Valve:

These valves are located on the suction line of the compressor and are used to facilitate servicing and repairs. - Discharge Service Valve:

Discharge service valves are placed on the compressor discharge line and, similar to suction valves, enable control and isolation of flow in that section. - Core Valve or Schrader Valve:

These valves are used for pressure testing and refrigerant charging and have a self-closing mechanism. - Crankcase Pressure Regulator (CPR):

This regulator keeps the compressor crankcase pressure within a safe range to prevent compressor damage. The CPR system is a well-known solution in this context. - Head Pressure Control Valve:

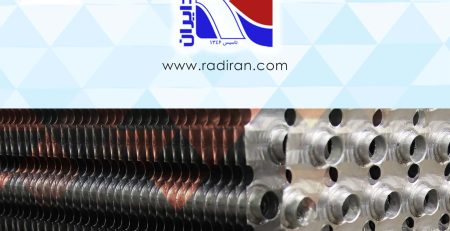

This valve adjusts the condenser pressure to ensure optimal system performance under different ambient conditions. - Evaporating Pressure Regulators:

Installed in the evaporator, these regulators control the internal evaporator pressure to ensure proper refrigerant evaporation. - Solenoid Valve:

Solenoid valves automate the on/off control of refrigerant flow and provide the ability to control flow within the system. - Desuperheating Thermostatic Expansion Valve:

This valve reduces the superheat temperature of the refrigerant vapor and prevents excessively hot vapor from entering the compressor. - Liquid Receiver Service Valve:

This valve controls the flow of liquid refrigerant in the liquid receiver tank and is used during service and maintenance operations.