Dry cooler (air cooler) and its role in water conservation?

A dry cooler is essentially an air cooled condenser similar to the condenser of a chiller, but instead of refrigerant flowing through its tubes, any hot fluid can circulate—e.g., water, ethylene glycol/water mixtures, propylene glycol/water mixtures, chemical fluids, etc. A dry cooler consists of finned coils and fans; the hot fluid flows in a fully closed loop and rejects heat to the air that the fans force across the finned coils, thereby cooling the fluid. Dry coolers replace evaporative cooling systems such as cooling towers, so they do not require water. Because no evaporation occurs, there is no water consumption or need for water treatment additives.

Construction and layouts

Dry coolers are manufactured in two main arrangements—horizontal and V shaped—selected based on application and available space. Smaller units are sometimes built vertically, similar to a fan assisted radiator.

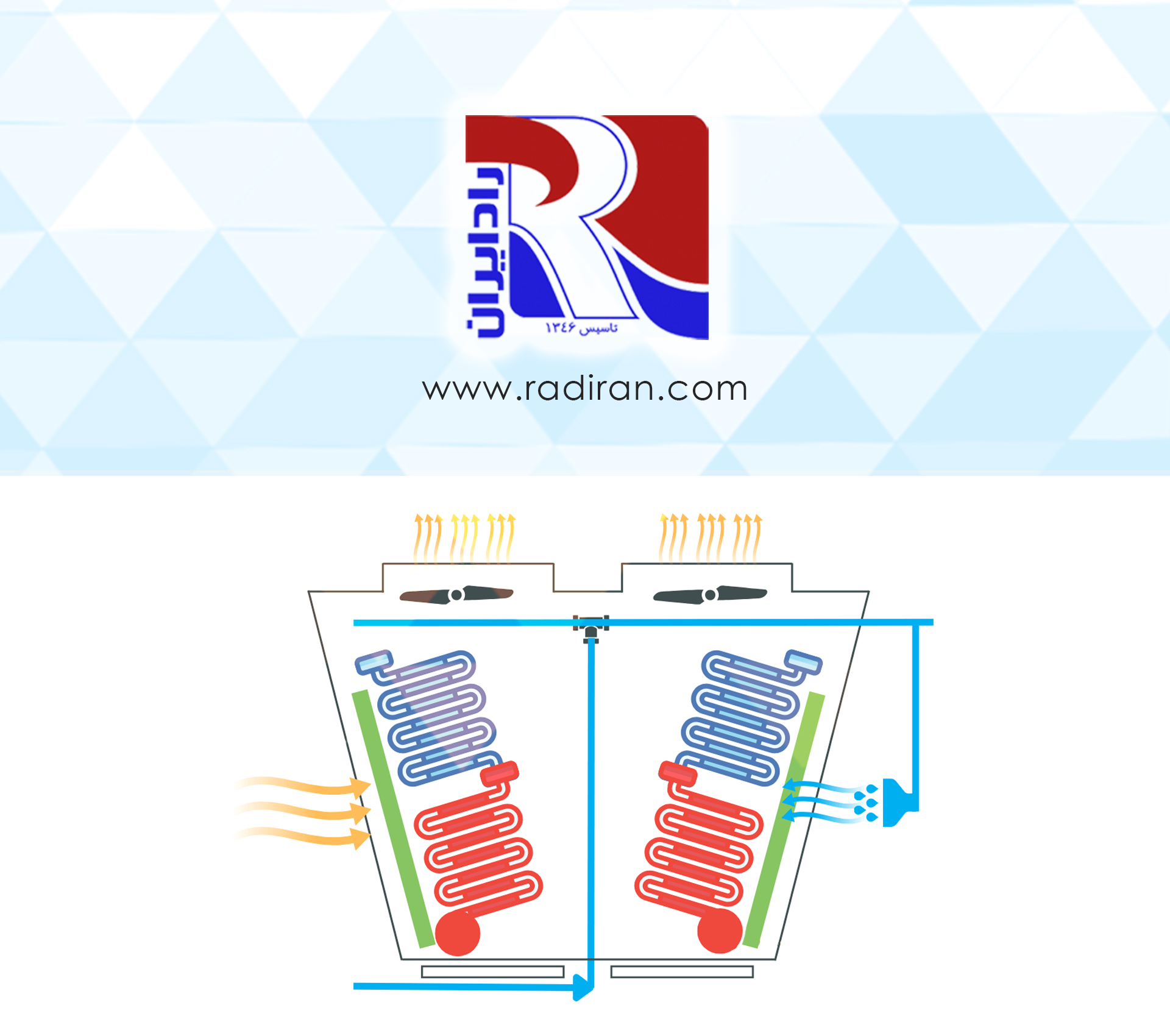

Operation (horizontal air cooled heat exchanger):

[illustration omitted]

V shaped dry cooler (V type air cooled heat exchanger):

[illustration omitted]

Fans and drives

These units commonly use direct drive fan motors (no gearbox) or belt drives, typically sourced from reputable global brands such as EBM and Ziehl Abegg or respected local manufacturers (e.g., Damandeh in Iran).

Applications

1. Data centers (high heat loads)

2. Hospital equipment

3. Industrial systems and machinery

4. Power generation plants

5. Cooling fluids for induction equipment

6. HVAC systems such as chillers, VRF, GHP

7. Large industrial internal combustion engines

Industry examples:

8. Steel industry—for cooling fluid of induction and arc furnaces

9. Refinery and petrochemical—for cooling and condensation

10. Rubber industry—for cooling roll coolant

11. Plastics industry—for cooling injection molding machine coolant

12. Textile industry—for steam condensation processes

13. Power plants—for lubrication oil cooling, intercoolers, etc.

Any application requiring air cooled cooling or condensation of a fluid can use a dry cooler.

Advantages of dry coolers versus water based systems (cooling towers)

1. No water required (air cooled).

2. Very low maintenance because no water or water additives are used.

3. No periodic water treatment/service cycles.

4. Use of curved finned tubes with high heat transfer coefficients allows higher cooling efficiency.

5. Usable in all climates, including humid conditions (cooling towers lose efficiency in humid climates).

6. Can circulate any fluid type in the dry cooler (whereas cooling towers can only handle water and only reduce water temperature).

For more on cooling tower features, pros and cons, see: Cooling tower .

Disadvantages compared with cooling towers

1. Higher initial cost.

Dry coolers are usually more expensive than cooling towers. However, this comparison should account for the cost of water treatment equipment (e.g., water softeners) required when feed water quality is poor; when those costs are included, the effective price gap narrows.

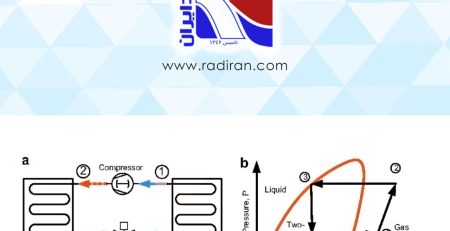

2. Lower thermal performance.

In a dry cooler, the process fluid is separated from air by the tube wall and transfers heat through the tube surface to the air. In a cooling tower, hot water contacts air directly, giving typically higher cooling capacity, but at the cost of water evaporation, water consumption, fouling, and the need for periodic cleaning and filtration.