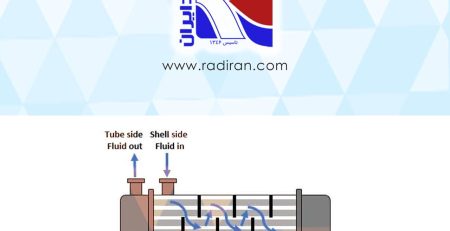

What Techniques Maximize the Service Life of Shell-and-Tube Heat Exchangers?

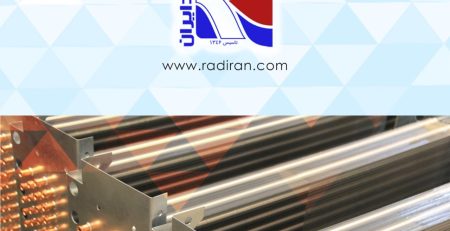

Shell-and-tube heat exchangers, owing to their simple structure, enable effective heat transfer between different fluids and are therefore widely used in many industrial applications, including hydraulic-oil coolers. By implementing certain techniques, the operational lifespan of a shell-and-tube heat exchanger can be significantly extended, preventing unexpected production downtime and avoiding additional repair costs. The following sections examine key strategies for increasing the service life of shell-and-tube exchangers.

Selecting a Shell-and-Tube Exchanger Based on Fluid Type

One of the most impactful measures to enhance the service life of a shell-and-tube heat exchanger is selecting the proper material according to the operating temperature, pressure, and fluid characteristics.

Exchangers constructed from stainless steel, nickel alloys, or titanium are ideal choices for corrosive fluids. For neutral fluids and mineral oils, carbon-steel shell-and-tube units are generally sufficient and cost-effective. Correct material selection mitigates corrosion, stress cracking, premature wear, and unexpected failure, thereby maximizing equipment durability.

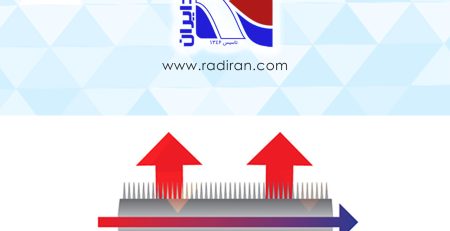

Precise Temperature and Pressure Control to Extend Exchanger Life

If a shell-and-tube exchanger is subjected to temperatures or pressures beyond its design limits, it can experience cracking, leakage, or even mechanical failure. To prevent such damage and extend service life, it is essential to use:

Accurate pressure gauges (manometers)

Reliable temperature sensors

High-sensitivity alarm systems configured to alert operators of any non-permitted temperature or pressure excursions

These monitoring tools protect the unit from thermal overstress, overpressure events, and long-term structural fatigue.

Periodic Cleaning and Maintenance: A Key Factor in Longevity

Descaling, gasket replacement, inspection for leakage and corrosion, and thorough cleaning of heat-transfer surfaces all contribute to improved efficiency and prevent premature degradation.

For this reason, experts recommend performing scheduled maintenance at least every six months, which helps:

Maintain optimal heat-transfer performance

Reduce fouling and corrosion rates

Prevent early mechanical or thermal failure

Regular servicing substantially extends operational lifespan and reduces unplanned outages.

Comprehensive Operator Training

In many cases, inexperienced or improperly trained operators may unintentionally cause significant damage to heat exchangers through seemingly small operational mistakes. By providing personnel with proper training—such as:

Daily normal operating temperature and pressure ranges

Key warning signs of malfunction or deterioration

Proper startup, shutdown, and inspection procedures

—organizations can substantially reduce operational risks and enhance the lifetime performance of shell-and-tube exchangers.