Efficiency and Capacity of Coils

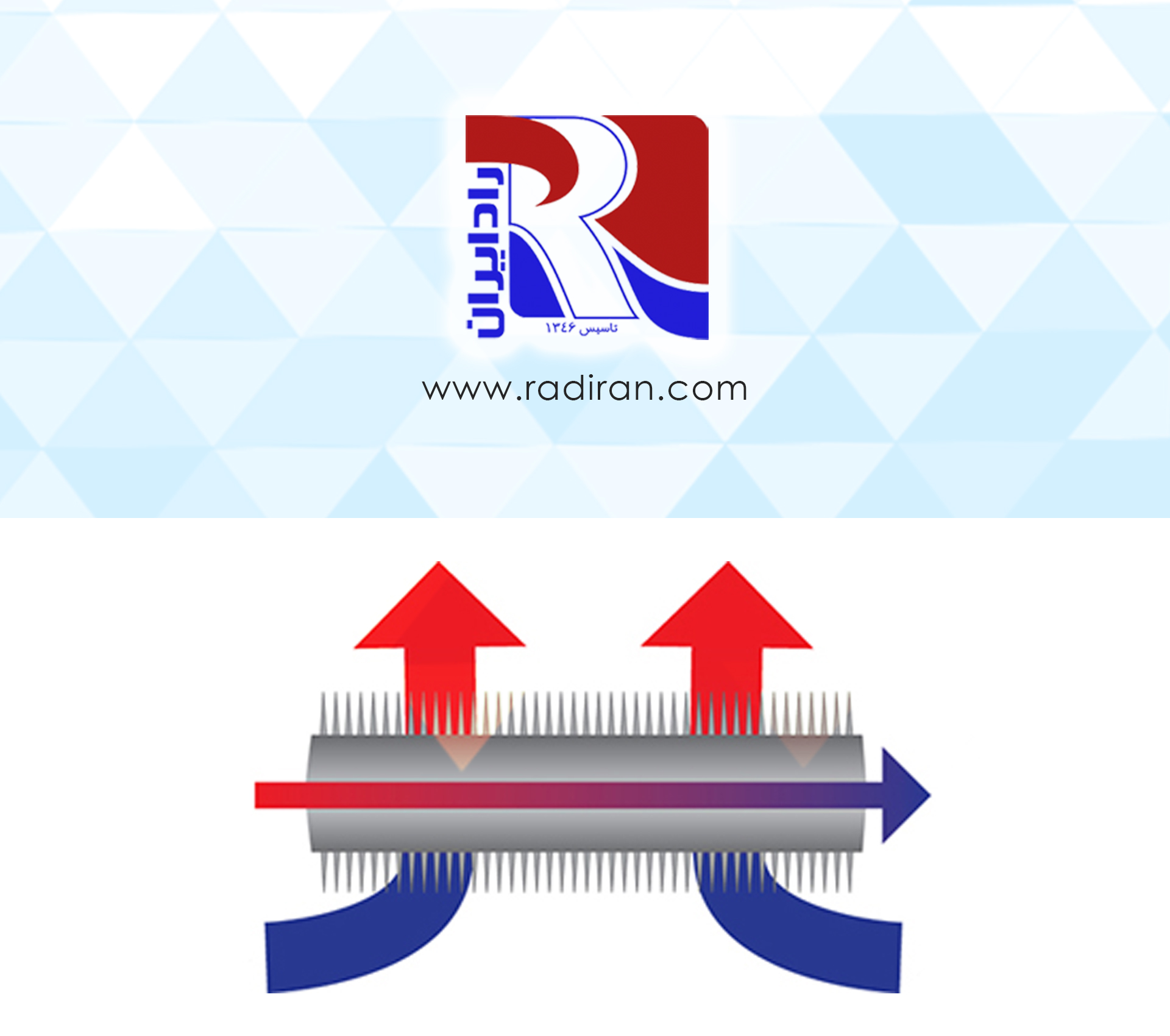

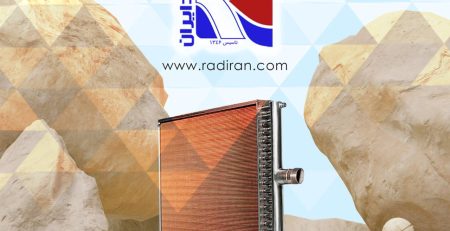

Fin tube coils are present in many process heating systems and are typically the first components to show signs of improper filtration upstream. In environments where contamination is an issue, these coils can lead to significant problems, including pump failures, compressor issues, and fan malfunctions. These coils, also known as heat exchange coils, consist of two main parts for heat transfer: the first part is the tubes, referred to as the primary surface, and the second part is the finned surface or secondary surface.

These two components play an essential role in creating balance in heat transfer through resistance on the air and water sides. The tubes transfer energy between the fluid inside them and the surrounding environment.

In heat exchange coils, heat is transferred from the warmer stream to the cooler stream. In chilled water coils, the water temperature is higher than the air temperature, which allows heat to be absorbed from the air and transferred to the water. In heating coils or thermal fluid coils, the hot water or thermal fluid has a higher temperature than the air, thus transferring its BTU/hr capacity to the air.

Fins in these coils perform two primary functions: first, they direct the incoming air in a specific direction. Typically, process fans distribute air in a spiral pattern, but the fins redirect this swirling air into a straight path, allowing the air to flow more uniformly across the primary surface.

The second role of the fins is that they contribute to the heat transfer themselves. The heat transfer from the tubes to the fins increases the overall heat transfer capacity of the coil, which is why they are referred to as secondary heat transfer surfaces.

Principles of Coil Selection

The correct selection of a coil should be based on meeting the following requirements:

• Heat Transfer (BTU/hr)

• Fluid Pressure Drop

• Air Pressure Drop

To optimize the selection, it is essential to maintain a balance among these factors. You cannot fulfill just one or two of these requirements while neglecting others.

For example, suppose the selected coil meets the heat transfer load and water-side pressure drop requirements, but the air-side pressure drop is high. In this case, the fan is selected based on the amount of air it must move against the total static pressure. If the coil resistance is too high, the fan will move less air, leading to a reduction in the overall system capacity.

Designers and owners of processing equipment must be aware that changes in the system over the life of the coil can significantly impact its efficiency and capacity.