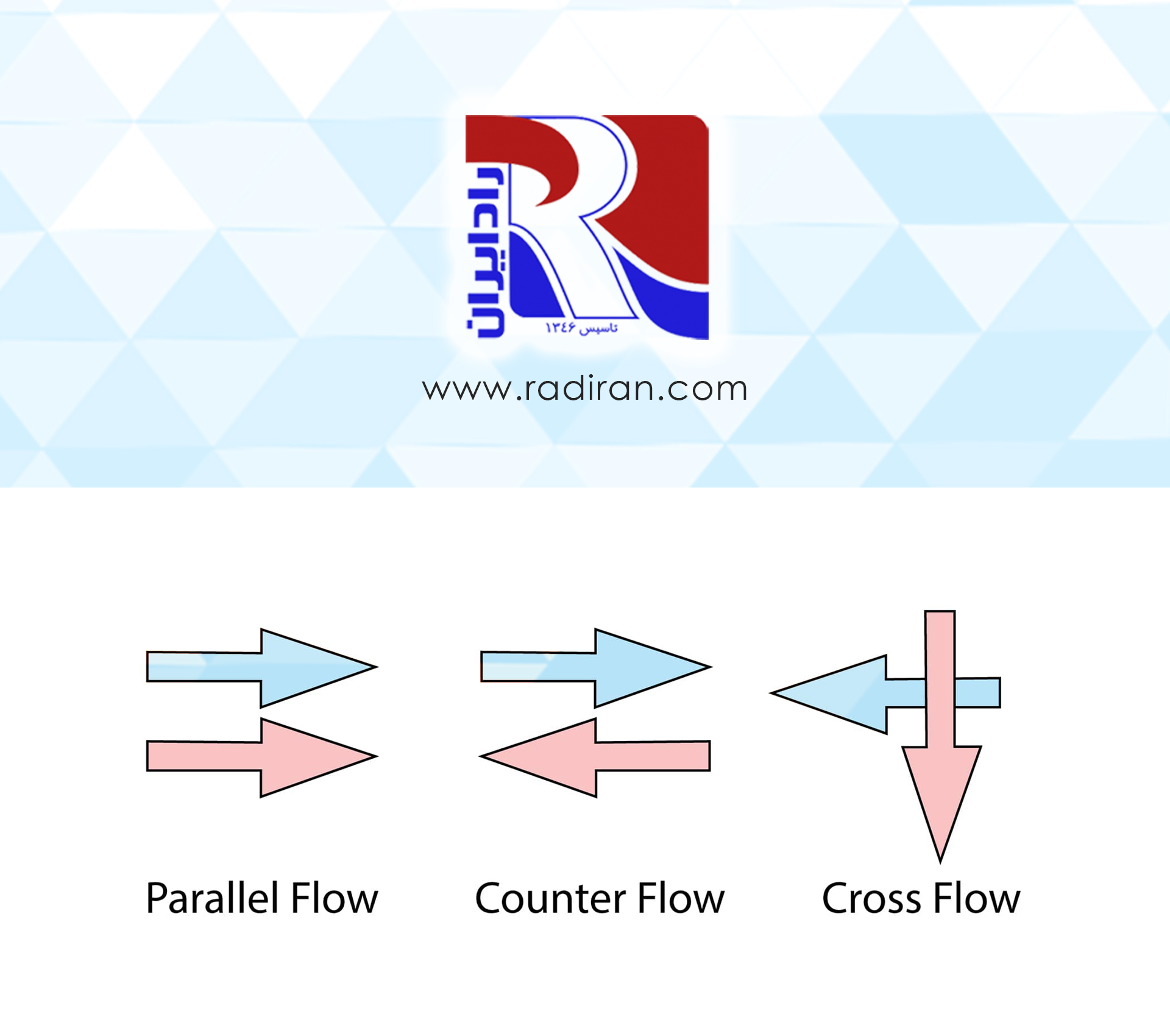

Analysis and Comparison of the Effects of Crossflow and Parallel Flow (Co-flow and Counter-flow) on Heat Transfer and Performance Parameters in Finned Tube Coils

Finned tube coils are essential components in heating, ventilation, air conditioning (HVAC), and refrigeration systems, where efficient heat transfer between fluids and air is paramount. In these systems, the direction of fluid flow relative to the airflow—typically classified as crossflow, parallel co-flow, or parallel counter-flow—significantly impacts thermal performance and operational parameters. This study aims to analyze and compare the effects of these flow configurations on heat transfer efficiency, pressure drop, and overall coil effectiveness.

Flow Configurations in Finned Tube Coils

Crossflow configuration occurs when the air flows perpendicular to the axis of copper tubes with aluminum fins, which enhances turbulence and typically increases heat transfer. Parallel flow, on the other hand, refers to scenarios where air and the working fluid flow in the same (co-flow) or opposite directions (counter-flow) along the coil axis. Each flow arrangement offers distinct advantages and trade-offs regarding heat transfer rates and hydraulic resistance.

Heat Transfer Performance

In crossflow arrangements, the air encounters the tubes laterally, inducing complex flow patterns and localized vortex shedding around the tubes and fins. This turbulence augments convective heat transfer coefficients and generally results in higher overall heat transfer rates compared to parallel flows. However, the pressure drop on the air side may increase due to the interrupted flow path.

Parallel flow configurations show differing thermal behaviors depending on the directionality. Co-flow, where air and fluid move in the same direction, often results in a smaller temperature gradient between the fluids, potentially limiting the maximum achievable heat transfer. Counter-flow, conversely, maintains a higher thermal gradient over the coil length, allowing for improved heat exchanger effectiveness and thermal performance, especially when temperature differences between the fluids are critical.

Pressure Drop and Energy Considerations

The hydraulic performance in each configuration also varies. Crossflow arrangements, while promoting turbulence, typically induce higher pressure drops due to flow disruption around the fins and tubes. This effect translates to greater fan power requirements for air movement, impacting system energy efficiency.

In parallel flows, pressure drops are often lower, particularly in co-flow situations where flow alignment reduces flow disturbances. However, the somewhat lower turbulence levels may reduce convective heat transfer coefficients, necessitating longer coils or larger surface areas to achieve desired thermal loads, which could inadvertently affect system volume and cost.

Influence of Design Parameters and Operating Conditions

In practical applications, geometric factors such as fin pitch, tube diameter, and fin shape interact with flow configuration to determine overall coil behavior. For instance, finer fin pitches in crossflow setups enhance heat transfer but exacerbate pressure drop. Similarly, material properties and fluid velocities alter convective coefficients distinctly in each flow arrangement.

Environmental and operational conditions—including air humidity, dust particulate presence, and temperature ranges—may also influence which flow configuration performs best. For example, crossflow designs generally facilitate better self-cleaning due to increased airflow turbulence, whereas parallel flows might accumulate particulates more rapidly, affecting long-term efficiency.

Conclusion

This comparative analysis highlights that while crossflow finned tube coils tend to achieve higher heat transfer coefficients due to increased turbulence and fluid mixing, they also incur higher pressure drops and associated energy penalties. Parallel flow configurations, particularly counter-flow, offer a balanced compromise between thermal effectiveness and hydraulic performance, often excelling in applications where temperature approach requirements are stringent.

The choice between crossflow and parallel flow (co-flow or counter-flow) should be guided by specific application requirements, including desired thermal performance, allowable pressure drop, space constraints, and maintenance considerations. Integration of computational fluid dynamics (CFD) modeling and experimental validation is recommended for optimizing coil design tailored to intended operational environments.