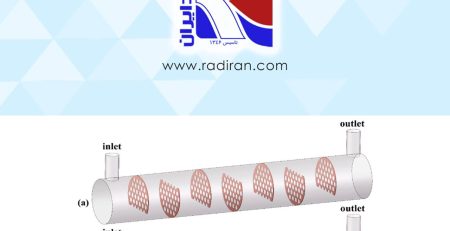

How to Extend the Service Life of Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers are predominantly used in facilities such as refineries and power plants. Consequently, the service life of these units has a direct impact on operational efficiency, auxiliary costs, and maintenance expenditures. Increasing the lifespan of a shell-and-tube exchanger requires adherence to several essential practices, the most important of which are outlined below.

Regular and Proper Cleaning of the Exchanger

Since shell-and-tube heat exchangers in refineries and power plants are typically exposed to chemical substances and deposit-forming fluids, experts strongly recommend regular, methodical cleaning using appropriate cleaning solutions and periodic flushing. Such maintenance prevents fouling buildup, ensures proper heat transfer, and reduces long-term operational stress on the equipment.

Monitoring Operating Conditions and Fluid Quality

Continuous monitoring of the exchanger, its operating conditions, and the temperature and pressure applied to the shell-and-tube unit can significantly extend its service life. It is also recommended that the working fluid entering the exchanger pass through standard filtration systems, with its pH and temperature checked at regular intervals. Maintaining optimal fluid quality reduces corrosion, scaling, and thermal stress within the unit.

Routine Inspection

Although periodic inspection and assessment of a shell-and-tube exchanger may appear costly from a financial standpoint, such inspections remain essential. They can identify potential defects before they escalate into critical failures. If any component is found to be worn and in need of repair or replacement, timely intervention can restore the unit’s performance at a lower cost and within a shorter downtime period.