Bypass factor in a fin-and-tube coil

Bypass factor in the airflow passing over a fin-and-tube coil is an important parameter in the design and performance of heat-exchange systems. This factor represents the portion of the air stream that passes through the coil without effective contact with the heat-transfer surfaces (i.e., through the fins and tubes) and therefore does not participate in heat exchange, relative to the total airflow. Bypass is especially likely in fin-and-tube coils with improper fin arrangement, uneven fin spacing, or high air velocities, and it can reduce cooling or heating effectiveness.

Benefits of knowing and controlling bypass factor:

- Optimization of performance: Determining the bypass factor allows coil design to be adjusted so that the maximum amount of air contacts the fin-and-tube surfaces, increasing heat-transfer capacity.

- Energy savings: Reducing bypass decreases the need for higher airflow rates or increased fan speed to achieve the desired capacity, leading to lower power consumption.

- Improved temperature distribution and thermal comfort: Lower bypass helps produce a more uniform outlet-air temperature from the coil and reduces local cold or hot spots.

- More accurate performance prediction: Knowing the bypass factor enables more accurate heat-transfer and fluid-dynamics modeling, supporting better engineering decisions.

Factors affecting bypass factor:

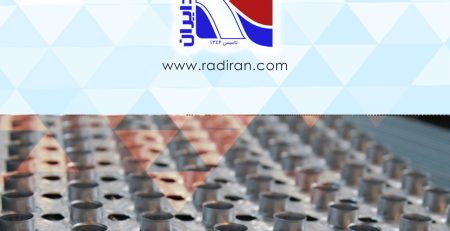

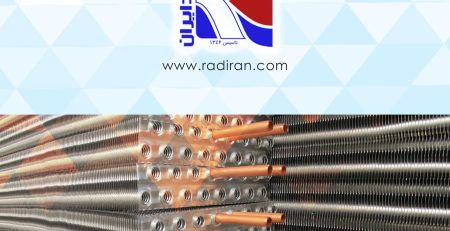

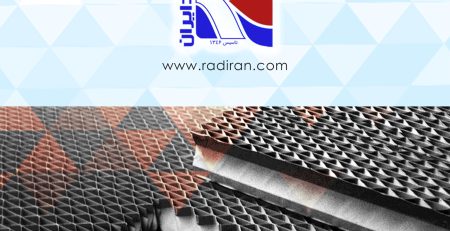

- Fin geometry and arrangement: Fin type (plain, louvered, wavy), fin spacing (fin pitch), and tube layout influence airflow paths and the tendency for air to bypass effective heat-transfer regions.

- Air velocity and flow distribution: At very high velocities, transient flow separation increases and bypass can be higher; uneven inlet airflow (for example from a poorly designed flange or duct) also increases bypass.

- Pressure profile and pressure drop: If pressure drop through the fin-tube matrix is high, air will tend to take lower-resistance bypass paths; controlling pressure drop through proper design can reduce bypass.

- Fouling and blockage: Dust or deposits that cover fin surfaces block effective heat-transfer paths and force air to bypass, increasing the bypass factor.

- Coil geometric aspect ratios: Height-to-depth ratio, tube length, and number of tube rows affect flow patterns and bypass.

- Thermal conditions and air properties: Temperature differences and changes in air density can alter flow patterns, especially when natural and forced convection combine.

Conclusion:

Bypass factor is a key parameter for evaluating fin-and-tube coil performance. By analyzing and optimizing fin geometry, airflow distribution, and regular maintenance, bypass can be reduced, heat-transfer effectiveness improved, and energy consumption lowered. For more precise calculations, laboratory testing or computational fluid dynamics (CFD) simulations together with empirical correlations are commonly used.