Industrial Air Handler and Water Coils Roles

Introduction:

Industrial air handlers are devices designed to provide clean and hygienic air for various environments, particularly in large and small industries. These systems are built with high airflow capacity to reduce airborne pollutants and create better conditions for workers.

Advantages of Industrial Air Handlers

• High Efficiency: Effectively and optimally operates under various conditions.

• Temperature and Humidity Control: Offers precise adjustment of temperature and humidity to create a suitable environment.

• Very High Airflow Capacity: Provides large volumes of clean air for expansive spaces.

• Elimination of Bacteria and Pollutants: Improves air quality by reducing microbial contaminants.

• Distribution of Clean Air for Workers: Creates a healthy and hygienic atmosphere for employees.

• Uniform Distribution of Comfortable Air: Prevents hot and cold spots in the workspace.

Pollution in Industrial Environments

Industrial environments typically contain various pollutants, such as suspended particles, dust, and chemicals. These contaminants can easily enter workers’ bodies through respiration. Industrial air handlers purify the ambient air, removing a significant amount of these pollutants and providing clean air.

Components of High-Capacity Air Handlers

• Fans: For circulating and transporting clean air in the space.

• Filters: For separating pollutants and suspended particles.

• Insulation: To prevent energy loss and increase system efficiency.

• Mixing Chamber: For combining fresh air with indoor air.

• Cooling and Heating Coils: For regulating temperature and creating optimal conditions.

• Humidifiers and Dehumidifiers: For controlling humidity levels.

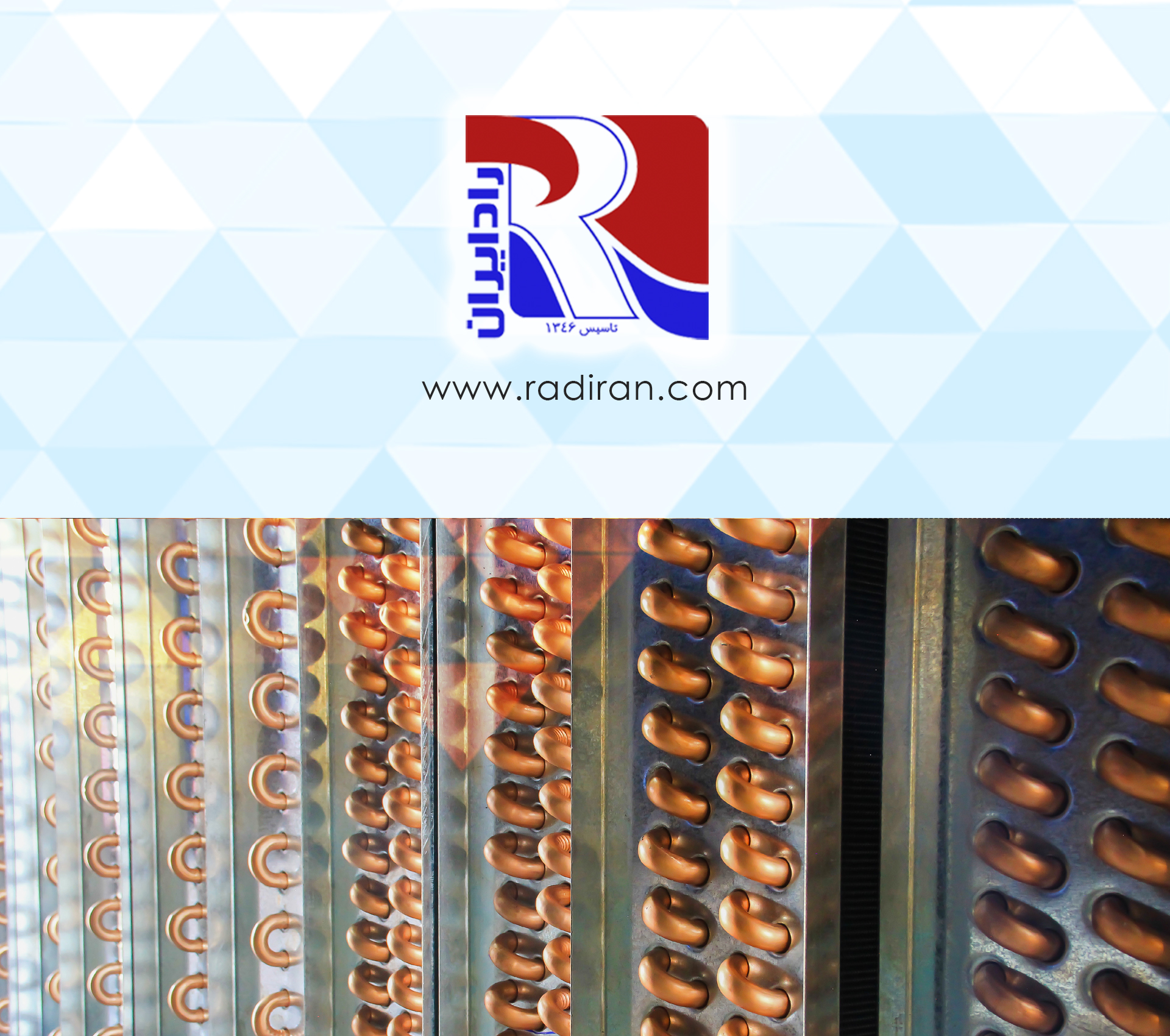

Role of Fin and Tube Coils

Fin and tube coils play a crucial role in the cooling and heating processes of industrial air handlers. These coils, equipped with suitable heat exchangers, provide the necessary capability for heat transfer. In cooling coils, cold water flows through the tubes and absorbs heat from the indoor air, ultimately delivering cooler air to the space. Conversely, in heating coils, hot water heats the passing air. The fin design increases the surface area for heat exchange, thereby enhancing system efficiency. These processes significantly contribute to improving indoor air quality and creating optimal conditions in industrial environments.

Applications of Industrial Air Handlers

• Server Rooms: Maintaining appropriate temperature and humidity for electronic equipment.

• Mushroom Cultivation: Providing optimal humidity and temperature for mushroom growth.

• Ventilation of Factory Spaces: Ensuring clean and healthy air for manufacturers.

• Ventilation of Administrative Areas in Factories: Enhancing workplace air quality.

• Comfort Ventilation in Highly Sensitive Environments: Such as laboratories and hospitals.