Modeling Fluid Flow and Heat Transfer in Aluminum Fin Coils with Copper Tubes in Dust-Contaminated Environments

Aluminum finned coils equipped with copper tubes are among the most widely used components in HVAC systems and industrial cooling and heating equipment. These coils combine the favorable properties of aluminum fins and copper tubes, resulting in high thermal efficiency and broad applicability across various environments. However, one of the significant challenges faced especially in industrial and urban environments is contamination of coil surfaces with suspended particles, dust, and airborne pollutants, which can severely degrade heat transfer efficiency and increase energy consumption.

Importance of Studying the Impact of Suspended Particles

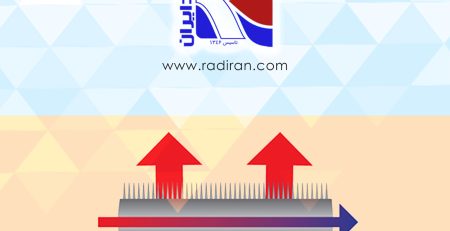

The accumulation of dust and particulate matter on fin surfaces acts as a thermal insulation layer, reducing the heat transfer coefficient and overall coil performance. Additionally, dust buildup can obstruct airflow passage and increase pressure drop, leading to higher energy consumption by fans and accelerated wear of mechanical components. Therefore, accurately understanding the effects of such contamination through fluid flow and heat transfer modeling is vital for coil design and maintenance.

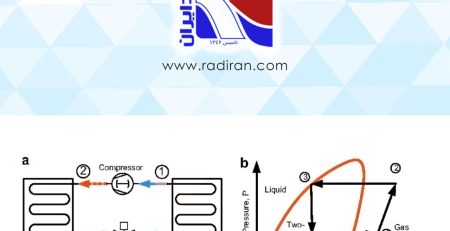

Fluid Flow and Heat Transfer Modeling Methods

Computational Fluid Dynamics (CFD) and heat transfer analysis are powerful tools for predicting coil behavior under dust-contaminated conditions. These techniques enable simulation of temperature distribution, pressure drop, and velocity profiles under realistic operating scenarios. Modeling also helps evaluate how sediment layers affect the thermal resistance at the fin surface and the resulting deterioration of heat exchange performance.

Impact of Dust and Particulate Deposition on Thermal Performance

Research indicates that even thin dust layers can reduce heat transfer rates by 15% to 30%. The particulate deposits create an additional thermal resistance barrier between the fin surface and airflow, severely hampering heat exchange. Moreover, uneven accumulation of dust can generate localized temperature variations, potentially causing mechanical stress and fatigue in the coil materials.

Strategies to Mitigate Performance Degradation in Contaminated Environments

Optimizing fin geometry and selecting materials resistant to particle adhesion can partly address dust-related issues. Employing anti-fouling coatings and designing fins with particular shapes that promote vortex flows can reduce dust buildup and maintain thermal performance. Regular cleaning and maintenance schedules are also crucial for sustaining coil efficiency in dusty atmospheres.

Conclusion

Studying and modeling fluid flow and heat transfer in aluminum fin coils with copper tubes under dust-contaminated conditions is essential for optimizing design and extending equipment lifespan. CFD simulations provide precise predictions of contamination effects and aid engineers in developing effective maintenance and design solutions. Given the rising levels of environmental pollutants, addressing this challenge is increasingly critical to preserving energy efficiency and minimizing operational costs in cooling and heating systems.