Enhancing Heat Exchange Efficiency through Turbulent Flow in Fin Tube Coils

Efficient heat exchange is essential in various industrial processes, from HVAC systems to chemical reactors. One effective method to increase heat exchange rates is by inducing turbulent flow within fin tube coils. Radiran in This essay explores the significance of turbulent flow in enhancing heat exchange efficiency in fin tube coils.

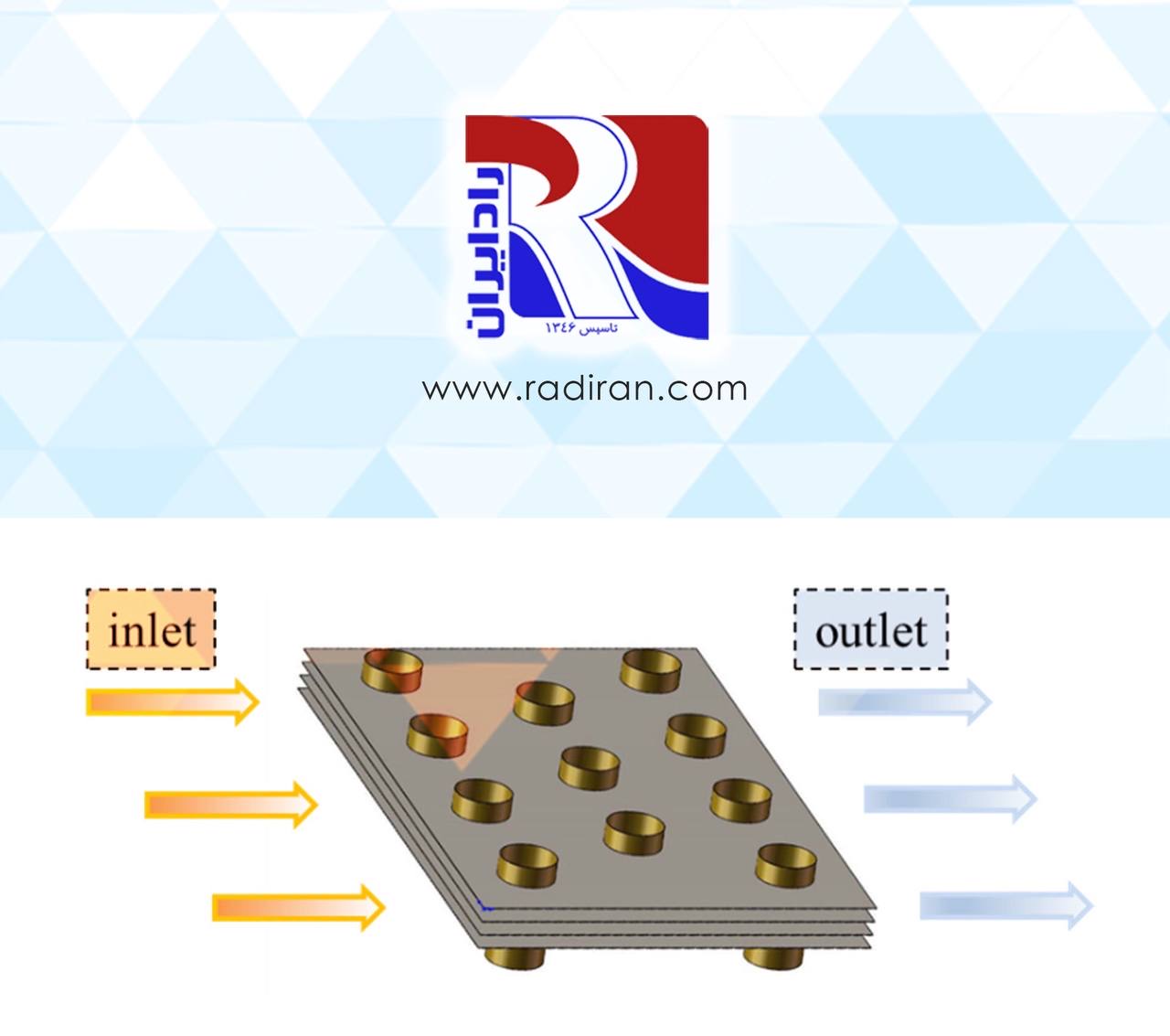

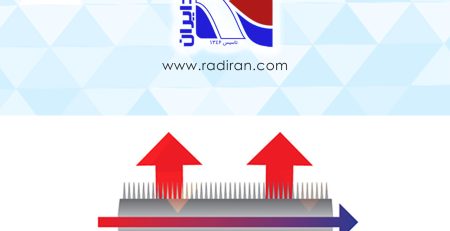

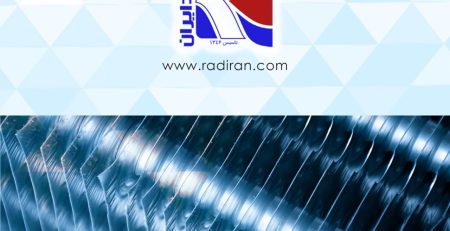

Turbulent flow occurs when fluid velocity becomes irregular and chaotic, characterized by swirling motion and enhanced mixing. In fin tube coils, turbulent flow disrupts the boundary layer near the surface, reducing thermal resistance and promoting heat transfer between the fluid and the surface of the tubes. This turbulent mixing increases convective heat transfer coefficients, leading to higher heat exchange rates.

The enhancement of heat exchange through turbulent flow is particularly beneficial in applications where heat transfer efficiency is critical. For example, in air conditioning systems, turbulent flow within fin tube coils improves the cooling capacity by maximizing the contact between the refrigerant and the coil surface. Similarly, in industrial processes such as oil refining and power generation, turbulent flow enhances the efficiency of heat exchangers, reducing energy consumption and operational costs.

Several factors influence the transition from laminar to turbulent flow within fin tube coils, including fluid velocity, geometry of the tubes, and surface roughness. By optimizing these parameters, engineers can design fin tube coils to operate under turbulent flow conditions, thereby maximizing heat exchange efficiency.

Moreover, advancements in computational fluid dynamics (CFD) have facilitated the simulation and analysis of turbulent flow behavior, allowing engineers to predict heat transfer performance accurately. In Radiran by leveraging CFD simulations, our engineers can optimize the design of fin tube coils to achieve the desired heat exchange rates while minimizing pressure drop and energy consumption in our manufactured coils.

In conclusion, inducing turbulent flow within fin tube coils is a highly effective strategy for enhancing heat exchange efficiency. By promoting turbulent mixing and disrupting the boundary layer, turbulent flow maximizes convective heat transfer, leading to improved performance in various industrial applications. As technology continues to evolve, Radiran will hire further advancements in design and simulation tools to enable even greater efficiency in our heat exchanger systems.