Technical Analysis of the Advantages and Limitations of Aluminum as Fins in Fin-and-Tube Coils

Proposed Abstract:

This paper presents a comprehensive examination of the reasons for using aluminum as the fin material in fin-and-tube coils. By reviewing thermal properties, heat transfer behavior, thermal conductivity, specific mass (density), corrosion resistance, formability, and manufacturing cost, we show that the combination of these characteristics makes aluminum well suited for HVAC, heating, and refrigeration applications. Additionally, the effects of fin design (fin density, thickness, and geometry), manufacturing processes (stamping, extrusion, and brazing), and performance metrics such as overall thermal resistance and air-side pressure drop are analyzed. Finally, the paper compares aluminum with common alternatives such as copper and stainless steel, and presents application scenarios and recommendations for future research.

Proposed Paper Structure:

1. Introduction

• Importance of fin-and-tube coils in HVAC and refrigeration systems

• Role of fins in increasing heat transfer surface area

• Objectives and scope of the study

2. Physical and Thermal Properties of Aluminum

• Density and effective mass

• Thermal conductivity (numerical comparison with copper and steel)

• Specific heat capacity

• Surface thermal conduction and the effect of fin thickness

3. Mechanical Properties and Manufacturability

• Ability to form thin fins (stamping and extrusion processes)

• Resistance to fatigue and impact

• Considerations for fin-to-tube joints (welding, brazing, mechanical bonding)

4. Corrosion Resistance and Environmental Stability

• Formation of a protective oxide layer and its effect on heat transfer

• Need for surface treatments and coatings (anodizing, polymer coatings)

• Behavior in wet and polluted environments (acids, chlorides)

5. Heat Transfer and Hydraulic Performance

• Channel/film heat transfer models for fin-and-tube configurations

• Effect of fin geometry (plain, louvered, corrugated, bonded) on heat transfer coefficient

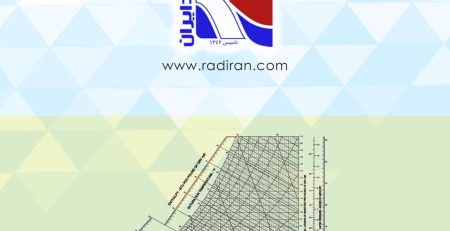

• Air-side pressure drop and optimization of fin spacing (FPI — fins per inch)

• Performance metrics (HTC, UA, NTU)

6. Economic and Manufacturing Aspects

• Material cost and life-cycle cost analysis

• Reduced weight and implications for installation and support structures

• Mass-production feasibility and quality control in aluminum fin manufacturing

7. Comparison with Alternative Materials

• Advantages and disadvantages vs. copper (higher conductivity of copper but higher cost and density)

• Comparison with stainless steel (higher corrosion resistance but lower thermal conductivity and higher cost)

• Situations where alternatives may be preferred (e.g., highly corrosive environments or very high-temperature service)

8. Case Studies and Experimental Data

• Laboratory heat transfer results for various aluminum fin specimens

• Life-cycle and failure analyses in field conditions

• Industrial examples in HVAC and chiller applications

9. Conclusions and Recommendations

• Summary of technical and economic reasons for selecting aluminum

• Design recommendations and future research directions (novel surface treatments, low-cost alloys with optimized conductivity, CFD-based modeling)