Fin Pitch Selection for Dusty and Polluted Air Conditions in Fin Tube Coils

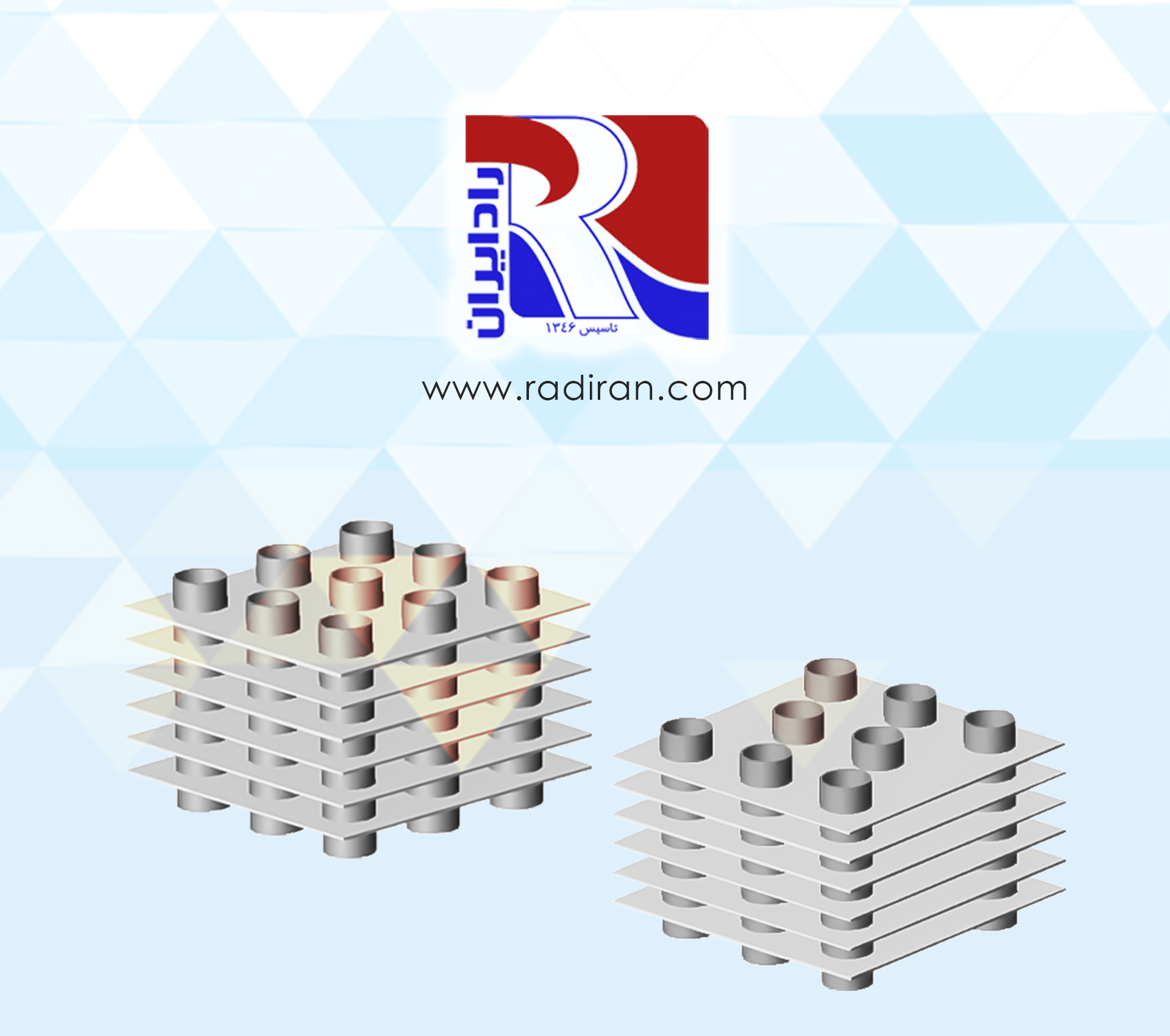

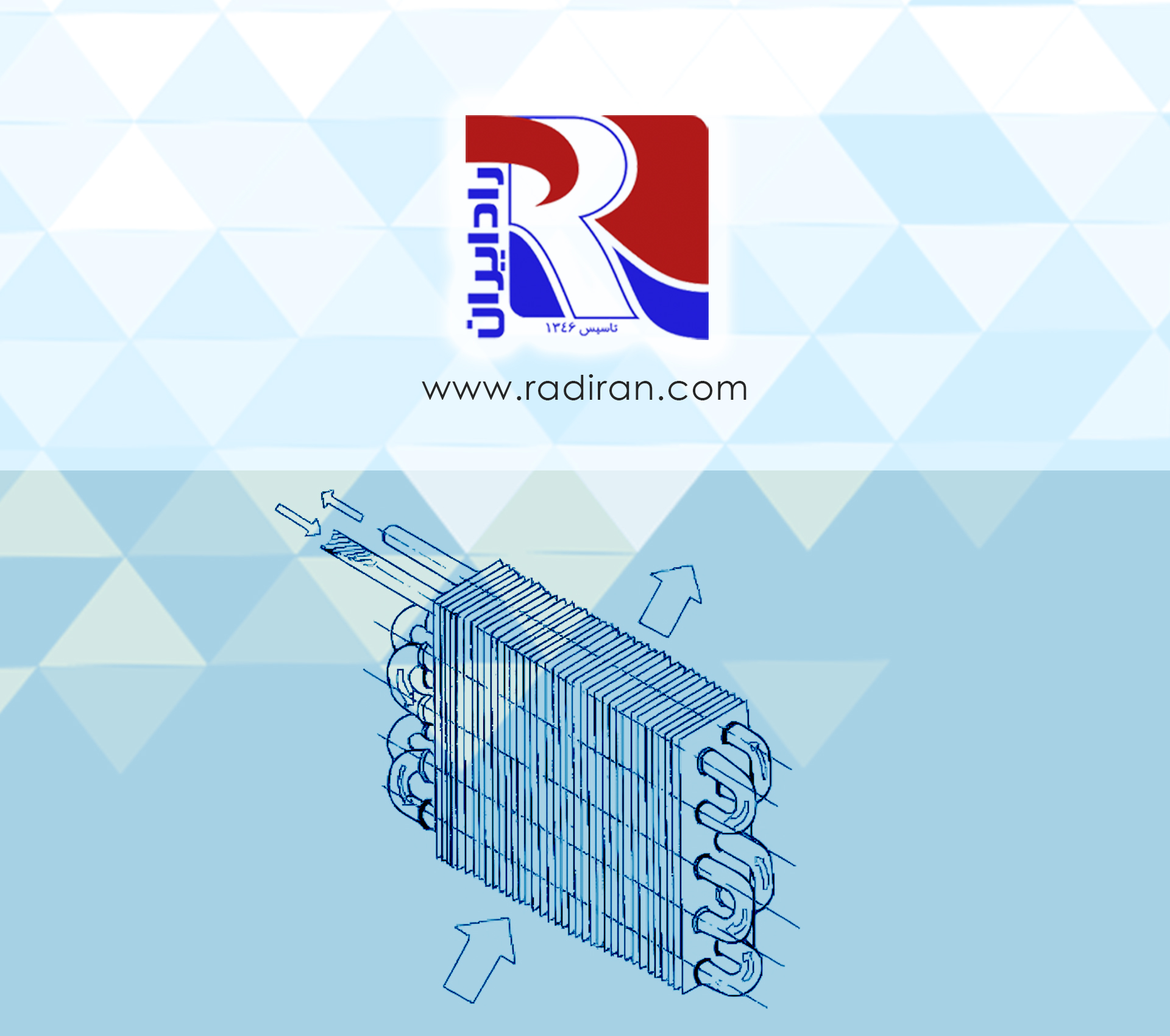

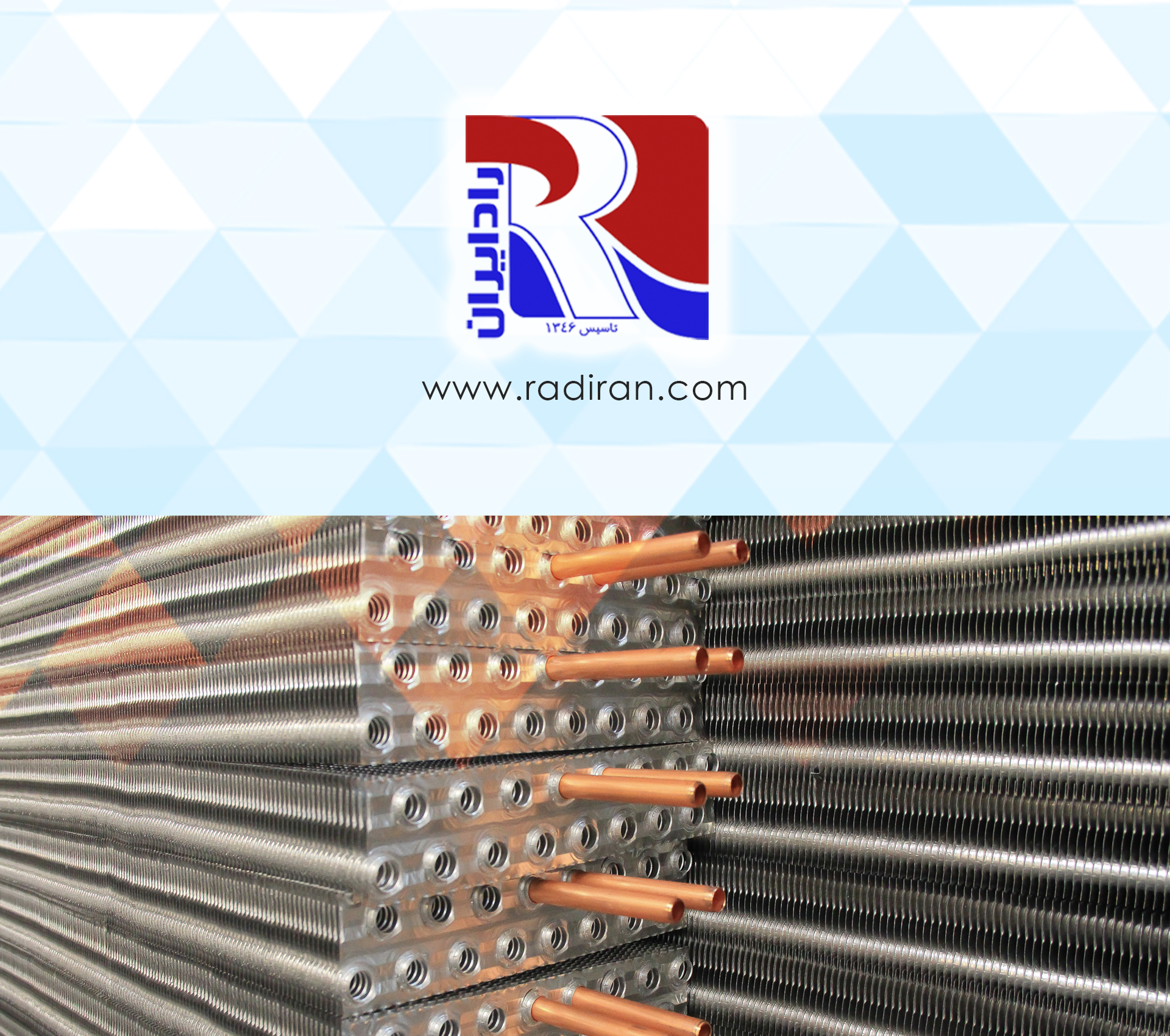

Introduction In fin-tube coils used for heat exchange, selecting the fin pitch (spacing between fins) is critical for thermal performance and long-term reliability, especially in dusty or polluted atmospheres. An improper fin pitch can cause degraded heat transfer, excessive pressure drop, and more frequent maintenance. Factors affecting fin pitch selection • Type and concentration of contaminants: Environments with coarse particulate matter (industrial dust, sand) promote rapid accumulation on fins; therefore, wider fin spacing is recommended to reduce blockage. Environments with fine or sticky...