About Coils

The finned coil is known as one of the most important components of refrigeration and heating systems. These coils are found both in the evaporator and in the condenser. Removing it effectively makes air conditioning equipment unavailable altogether. Here we want to present you with an amazing number that shows the importance of fins in air conditioning systems. The fins are responsible for 65-70% of the heat transfer on each coil. Coil tubes are responsible for the remaining 30 to 35 percent. But what is the efficiency of the finned coil and what advantages does it bring us? What is the coil?

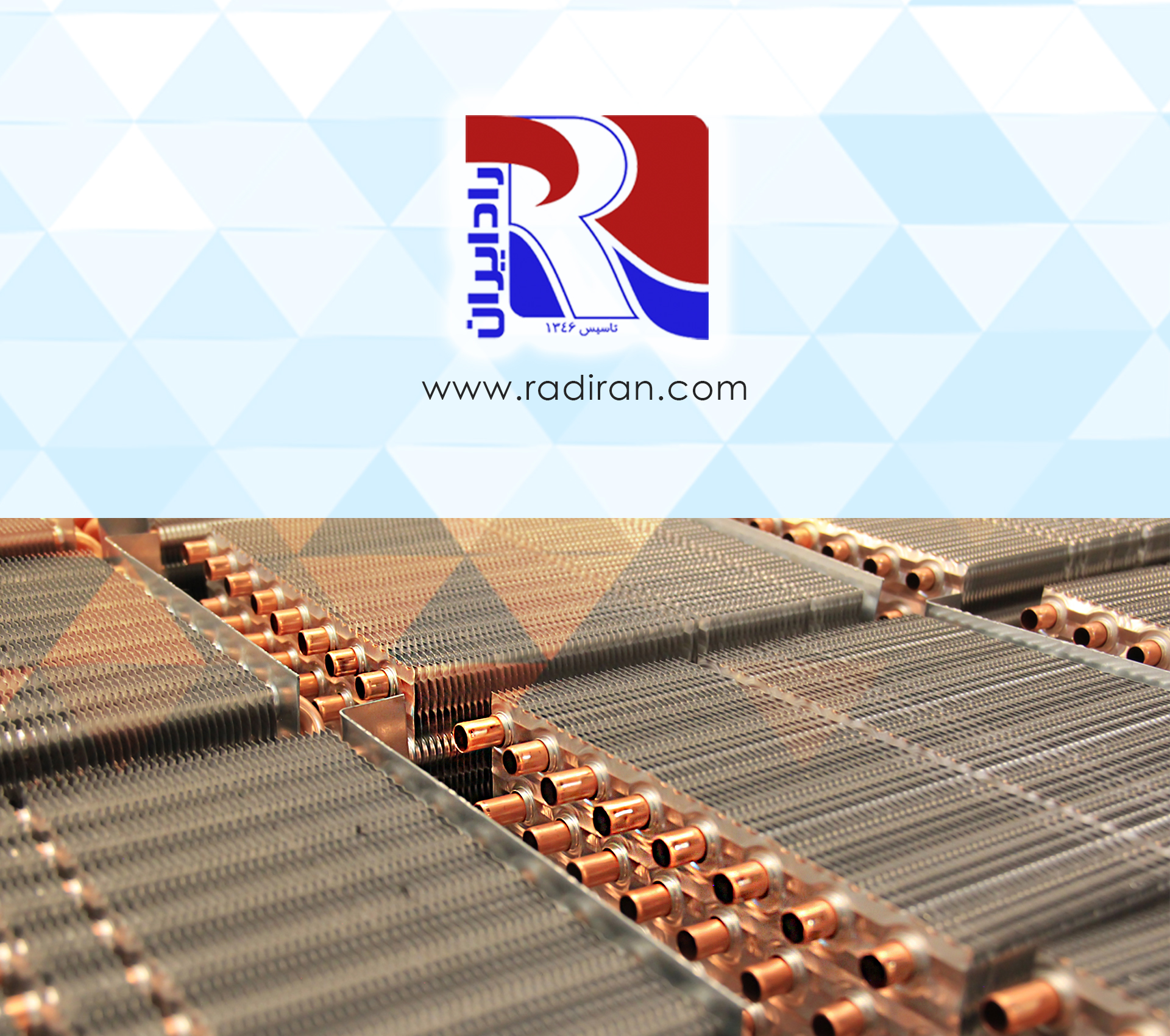

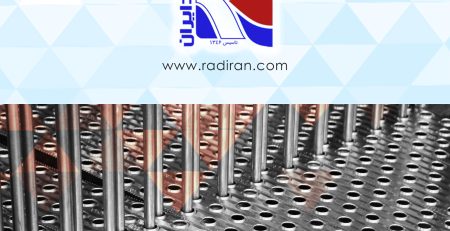

A coil is a copper or aluminum tube that plays the role of a heat and refrigerant exchanger. The cold or heat of water or gas is transferred through the coil, and this is the main use of this part. In the picture below, the bronze tubes are the coils.

Coils are used in all kinds of air conditioning equipment, such as fan coils, chillers, split ducts, etc. Depending on what system the coil is used in, its capacity should be determined. The heat and cold capacity of a coil are completely different. But what parameters are decisive for different capacities?

• How many square feet (SQ.FT) is the cross-sectional area of the coil (Face area)?

• How many inches is the diameter of the coil (Piping connection)?

• How many gallons per minute (GPM) should the water flow through the coil?

What is Finn?

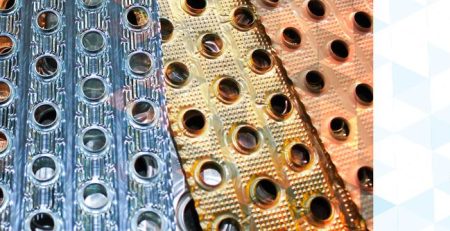

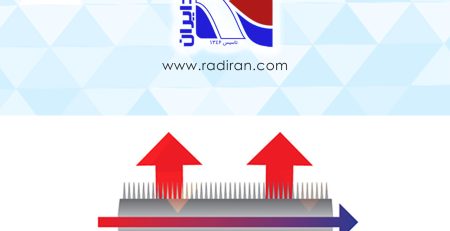

Fin, which is displayed as Fin in English, refers to surfaces that are used to increase the heat transfer rate between the surface and the environment, and are usually made of aluminum or copper. The fins are designed to help break up the airflow and facilitate an easy and direct airflow. Also, dirt or other particles in the air are easily trapped in them, which is why coils can act as excellent filters.

What is a finned coil?

Now that you are familiar with the concept of coil and fin separately, you should easily recognize what a finned coil is. The fins are connected to the coils in the form of blades and by increasing their cross section, they accelerate the heat transfer process. In order for the coil to function in the most optimal way possible, the way of connection between fins and tubes (fin/tube bond) is very important. Fins are known as secondary surface and tubes as primary surface. But as we said at the beginning of the article, this secondary surface is responsible for twice the amount of heat transfer compared to the primary surface.

finned coil

The density of fins in a coil is very important. The amount of this density is measured with a unit called fin per inch. For example, when it is said that 12 FPI is used in the built-in ceiling fan coil 800, it means that 12 aluminum fins are used per inch, or in another example, if it is said that 14 FPI is used in the condenser coil, that is, in There are 14 fins per inch, which means the fins are closer together.

The more the number of fins in one inch, the higher the capacity and efficiency of the equipment, but this also causes pressure drop in the fan. When the FPI level increases, the space between the fins actually decreases and the possibility of dirt and dust getting stuck between them increases. This problem is more visible especially in places where the amount of air and dust pollution is high or where a large number of carpets or rugs are used. It is also much more difficult to clean the space between the fins than when the FPI is lower. For this reason, it is necessary to use a correct fit for FPI to have good capacity and efficiency, and pollution between the fins does not cause problems for the equipment.