Common installation errors in heat exchangers

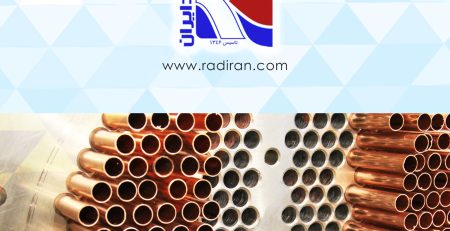

Common Installation Mistakes for Finned-Tube Coils Used as Water Heat Exchangers (Evaporator or Condenser)

Installing finned-tube coils in HVAC and refrigeration systems is common, but installation mistakes can severely degrade performance and reduce service life. Below are the most frequent errors and their technical consequences:

1. Incorrect orientation and flow direction

• Mistake: Installing the coil so that the air or fluid flow direction contradicts the manufacturer’s design (e.g., reversed tube routing or fan orientation).

• Consequence: Reduced heat transfer, localized hot/cold spots, increased pressure drop, and uneven corrosion.

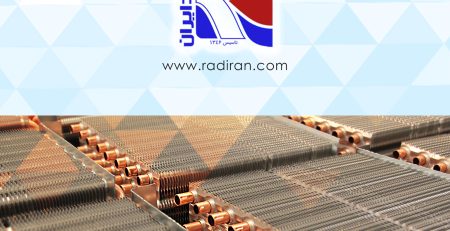

2. Violating tube bend radius and fin-to-tube spacing

• Mistake: Bending tubes with too-small radii or compressing fins during installation.

• Consequence: Flow restriction for fluid or air, accelerated fouling, reduced effective heat transfer area, and higher risk of tube leaks where stressed.

3. Improper supports and vibration isolation

• Mistake: Omitting supports or vibration isolators; inadequate mounting.

• Consequence: Transmitted vibration to piping and joints, material fatigue and leaks, and premature failure of fins and tubes.

4. Poor hydraulic connections (welding, brazing, mechanical joints)

• Mistake: Using inappropriate joining methods (overheating, incomplete braze, improper threading).

• Consequence: Fluid or refrigerant leaks, pressure loss, internal contamination, and costly repairs.

5. Incorrect piping slope and drain routing

• Mistake: Horizontal installation without proper slope or blocked drain paths.

• Consequence: Liquid accumulation at low points, reduced evaporation in evaporators, water hammer, and risk of compressor damage in refrigeration circuits.

6. Mismatched water flow rate or water quality

• Mistake: Supplying water with a lower flow rate or poorer quality than design (suspended solids, wrong pH, high chlorine).

• Consequence: Heavy scaling, chemical or electrochemical corrosion, degraded heat transfer, and fin/blockage.

7. Inadequate thermal and moisture insulation

• Mistake: Missing or insufficient insulation around the coil and adjacent piping.

• Consequence: Unwanted condensation, mold growth, reduced efficiency, and higher heating/cooling load.

8. Failing to install monitoring and control devices

• Mistake: Omitting thermometers, pressure gauges, regulating valves, or protective sensors at key points.

• Consequence: Inability to detect abnormal operating conditions early, risk of freeze or flood, and operation outside safe limits.

9. Neglecting service access and maintenance space

• Mistake: Locating the coil where cleaning, inspection, or repair is difficult.

• Consequence: Harder maintenance, higher service costs, and shortened system life.

10. Skipping flushing, cleaning, and pressure testing after installation

• Mistake: Not performing pipe flushing, internal cleaning, and hydrostatic testing after assembly.

• Consequence: Introduction of contaminants into the circuit, reduced performance, hidden leaks, and premature failures.

Brief conclusion: To ensure reliable performance and long life of finned-tube coils used as water heat exchangers, follow correct orientation and flow, maintain proper slope and supports, use correct joining techniques, control water quality and flow, insulate properly, install monitoring devices, allow service access, and perform thorough flushing and pressure tests. Preventing these common mistakes reduces failures, optimizes energy use, and increases system safety.