Aluminum star-shaped fin

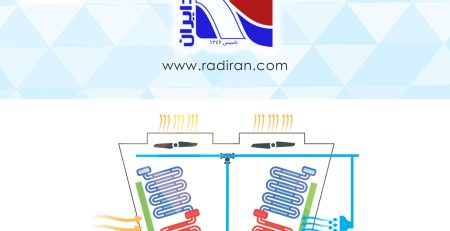

This study examines the effect of an aluminum star-shaped fin, placed along the axis of 5/8-inch copper tubes with a specific twist, on heat transfer in a shell-and-tube evaporator. The objective is to evaluate the enhancement of heat exchange and the reasons for using this geometric arrangement in refrigeration and HVAC applications.

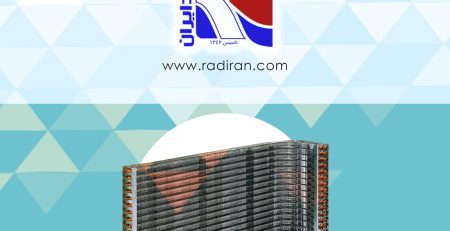

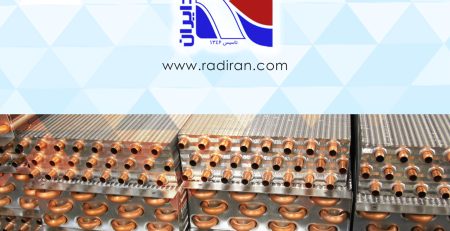

Fin design and configuration

The star-shaped fin is formed from aluminum sheet into a multi-branch profile that fits inside a 5/8-inch copper tube and is twisted gently around the longitudinal axis. This twist disturbs the flow inside the tube, promoting axial and radial mixing of the refrigerant. Aluminum is chosen for the fin because of its high thermal conductivity and low weight, making it suitable for fin construction.

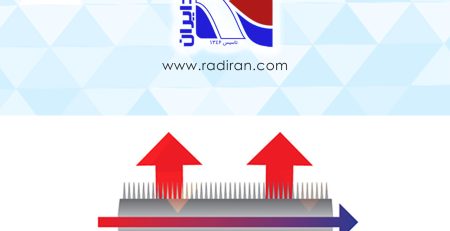

Effect on heat transfer

The star-shaped fin increases the heat transfer surface area between the refrigerant and the tube wall, boosting the overall heat transfer coefficient. The induced twist generates local turbulence and reduces the thermal boundary layer thickness; consequently, surface thermal resistance decreases and the heat transfer rate increases. In addition, the close thermal contact between the aluminum fin and the copper wall provides an effective conductive path for heat. Experimental and numerical studies of similar configurations have shown that twisted internal fins can increase the internal heat transfer coefficient significantly (in some cases by 20–50%, depending on flow conditions and design).

Reasons for use and advantages

Using a twisted star fin improves evaporator thermal performance, which can reduce the required tube length or number of tubes and optimize weight and cost. It also promotes more uniform temperature distribution and helps prevent internal hot spots. Overall, this approach is an effective way to increase the efficiency of shell-and-tube heat exchangers in refrigeration systems, particularly when space is limited or higher thermal capacity is required.