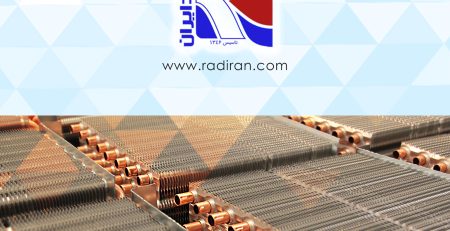

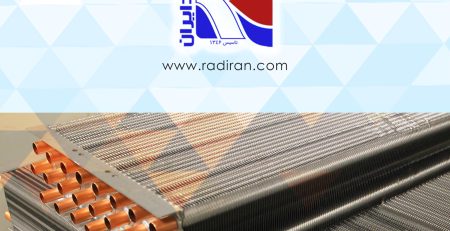

Elimination or Reduction of Air Gap between Aluminum Fins and Copper Tubes in Coils

Eliminating the air gap between aluminum fins and copper tubes in fin-and-tube heat exchangers (coils) is an important step in design and manufacturing that directly affects thermal performance, energy consumption, durability, and operating costs. This study examines why the issue matters, the effective heat-transfer mechanisms, technical and economic consequences, and practical implementation methods.

Importance of Contact-Based Heat Transfer

In fin-and-tube exchangers the primary objective is rapid and efficient heat transfer from the tube surface (carrying hot or cold fluid) to the air stream, or vice versa. When fins and tubes are in close physical contact, heat is transferred by conduction from the tube into the fin and then by convection from the fin to the air. As the air gap between these surfaces increases, the thermal resistance in the conduction path rises and heat flux decreases. Therefore, removing the air gap minimizes contact resistance and increases heat-transfer efficiency.

Effects on Pressure Drop and Overall Efficiency

Reducing the gap between fin and tube promotes a more uniform temperature distribution across the fin, which lowers local temperature differences with the air while increasing the average heat-exchange effectiveness. This can allow a reduction in fin size or number of tubes to achieve the same thermal capacity, improving system efficiency and reducing material and space costs. Conversely, if contact is poor, achieving desired heat transfer may require higher air velocity (increasing pressure drop), which raises fan energy consumption.

Mechanical Stability and Corrosion Durability

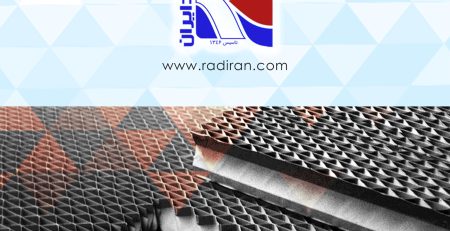

Inadequate air gap can permit relative motion or vibration between fin and tube during operation, causing mechanical fatigue, local failures, new gaps, and increased galvanic corrosion between aluminum and copper. Proper contact—often achieved by expanding (expanding the tube), crimping, riveting, or brazing—reduces relative movement and can produce a sealed joint that limits moisture and corrosive ingress. Consequently, exchanger service life increases and maintenance or replacement needs decrease.

Practical Measures to Eliminate Air Gaps

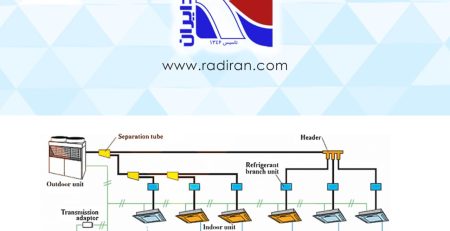

Common methods include mechanical processes (tube expansion, fin forming), using fins with grooves or serrations matched to the tube diameter, brazing or spot welding, and using thermally conductive adhesives or metal interlayers. At RadaIran company, an automatic tube-expansion (expand) process is used, which is considered the best solution for this issue. The appropriate method depends on operating conditions (working temperature, corrosiveness of the environment, serviceability requirements) and cost. Quality control in manufacturing, measurement of contact thermal resistance, and vibration and fatigue testing are among the actions that ensure reliable performance.

Conclusion

Removing the air gap between aluminum fins and copper tubes plays a key role in improving heat-transfer efficiency, lowering energy consumption, enhancing mechanical stability, and reducing corrosion. By applying suitable joining techniques and quality-control measures, the thermal performance of the exchanger can be significantly improved and operating and maintenance costs reduced. In exchanger design and production, careful attention to the physical contact between fin and tube is a determining factor for the functional and economic success of the system.