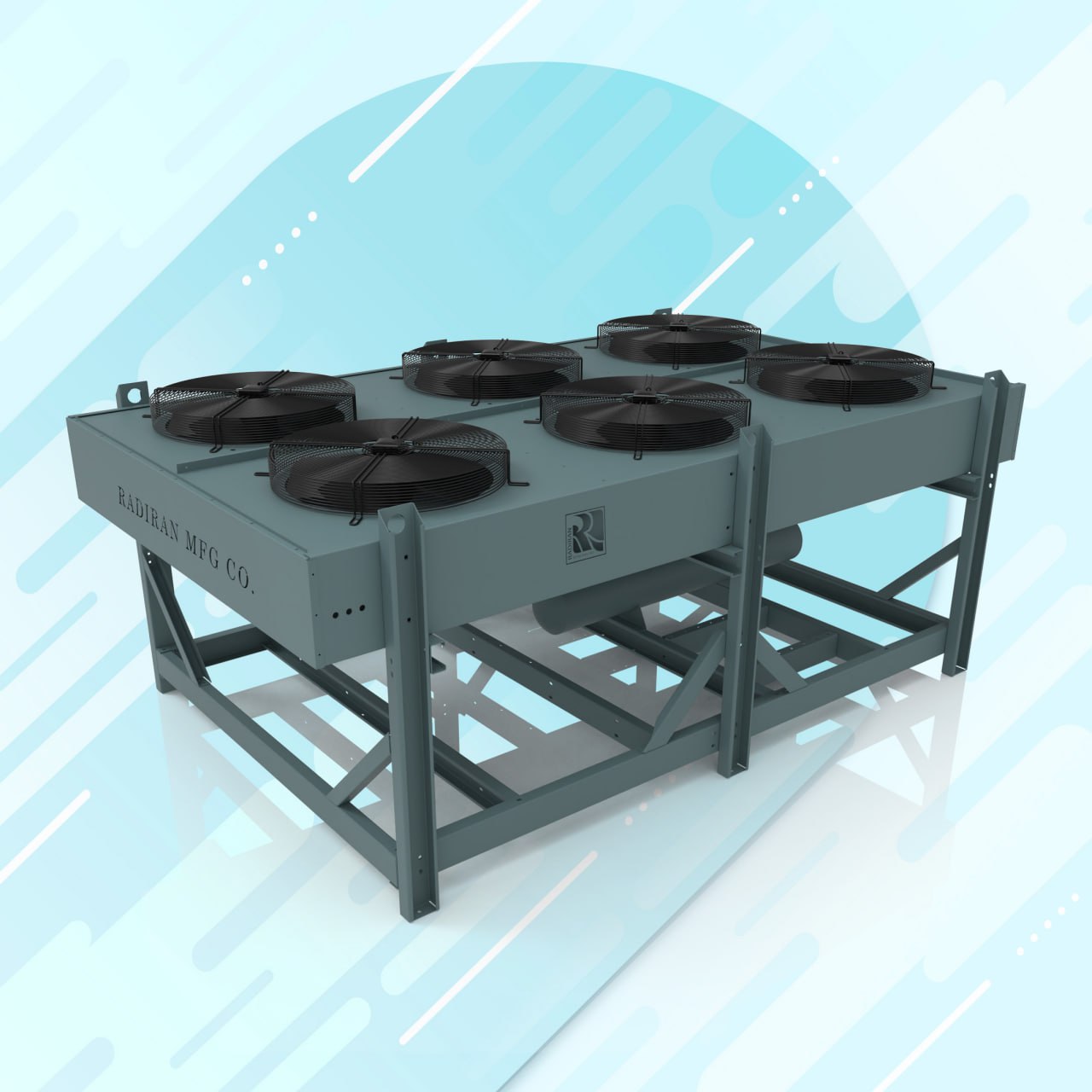

Cold-Room Condenser Unit: Applications and Key Purchasing Considerations

The efficiency of a refrigeration system in complexes and cold storage facilities is entirely dependent on selecting a cold-room condenser unit that is appropriate for the space. This article reviews the applications of cold-room condensers and highlights several key points to consider when purchasing this type of refrigeration equipment.

Applications of Cold-Room Condensers

Cold-room condenser units are most commonly used in the pharmaceutical, food, and agricultural industries, as well as in industrial freezers. Some food-storage warehouses are completely dependent on cold-room condensers and must purchase this equipment to maintain the quality of their products.

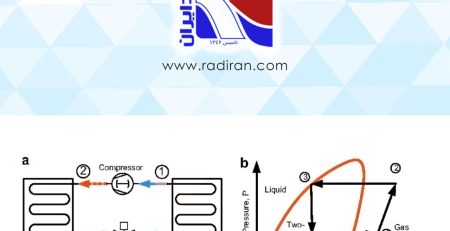

Paying Attention to Cooling Capacity

Each cold-room condenser has a specific cooling capacity, and when purchasing one, it is essential to ensure that its capacity matches the volume of the cold room and the type of stored products. Ignoring this issue can place excessive pressure on the system and may even increase energy consumption.

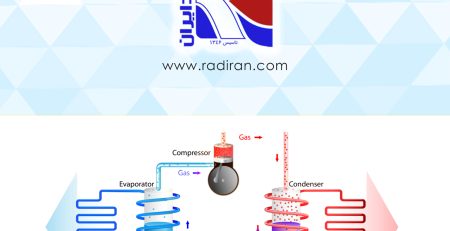

Choosing a Refrigerant Suitable for the Environment

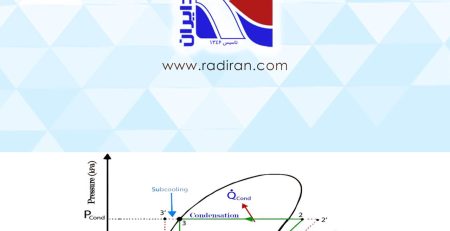

Among the different types of condenser refrigerants (air-cooled, water-cooled, and evaporative), one must select the refrigerant that best fits the working environment and delivers the highest efficiency in converting hot gaseous refrigerants and completing the refrigeration cycle.

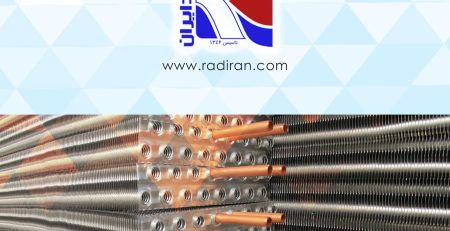

Ensuring Quality Through High-Grade Materials

When purchasing a cold-room condenser unit, if the lifespan of the facility’s equipment is important to you, then you must also consider the materials used in the condenser. Using copper and aluminum in the construction of tubes and fins can significantly increase the efficiency and lifespan of the cold-room condenser.

At Radiran, you have all of these together.