Air Washer in Industrial Warehouse HVAC: An Effective Cooling Solution

In industrial environments such as warehouses, HVAC (heating, ventilation, and air conditioning) plays a crucial role in maintaining a comfortable and safe working atmosphere. Due to the large space and high volume of air circulation, conventional cooling systems can be inefficient and costly. In this context, the air washer emerges as a specialized and cost-effective solution for cooling and air cleaning in industrial warehouses. This article reviews the structure, operation, and benefits of air washers in cooling warehouse air.

Structure and Main Components of an Industrial Air Washer

An industrial air washer consists of several key components that enable its overall functionality:

• Rotating Discs or Wet Packing Media: These are a set of plates or discs constantly wetted by water inside a basin. When warm air passes through these wet discs, the water evaporates, absorbing heat from the air and lowering its temperature.

• Water Reservoir and Recirculation System: The basin holds water that is continuously pumped to keep the discs wet, ensuring continuous evaporation and cooling efficiency. The water is typically recirculated to minimize consumption.

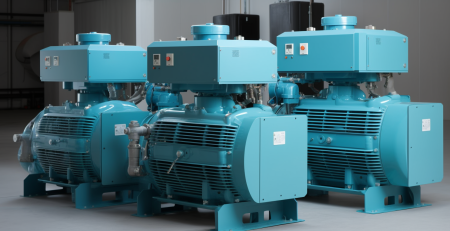

• Induced Draft Fan: This fan draws warm ambient air into the unit and pushes the cooled, humidified, and cleaned air into the warehouse space.

• Pre-Filtration System: Sometimes mechanical filters are installed at the air intake to remove large dust particles, improving both the evaporation efficiency and air quality.

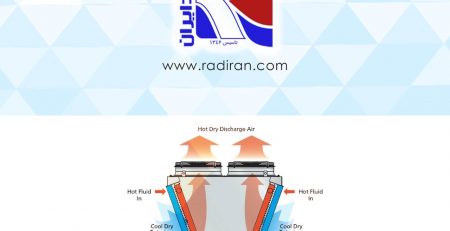

Technical Operation of Air Washer Cooling

The fundamental cooling process in an air washer is evaporative cooling, which relies on the physics of latent heat transfer. When water evaporates from the surface of the discs into the air stream, energy in the form of latent heat is absorbed from the air, causing the air temperature to drop. This process simultaneously increases the air’s relative humidity, an advantage in dry industrial environments.

Additionally, as air flows through the wet media, dust and particulate matter become trapped in the water, physically cleansing the air. This cleaning effect is especially beneficial in industrial settings where airborne dust and particulates are prevalent.

Advantages of Using Air Washers in Warehouses

• Energy Efficiency: Unlike traditional refrigeration systems and compressors, air washers consume significantly less energy since their cooling effect is produced by water evaporation rather than mechanical refrigeration cycles. This makes them ideal for cooling large volumes of air in warehouses.

• Simultaneous Cooling and Humidification: In hot, dry conditions, air washers increase indoor humidity levels, preventing the drying of air which can improve workers’ comfort and health.

• Dust and Particulate Removal: By washing the air, these systems help reduce contamination and dust accumulation, which is beneficial for both equipment longevity and workplace cleanliness.

• Simple Design and Low Maintenance: With straightforward mechanical components and no complex refrigeration parts, air washers are easier and cheaper to maintain and can be installed quickly.

Limitations and Considerations

Air washers are less effective in highly humid environments because their evaporative cooling capacity depends on the air’s ability to absorb moisture. Proper maintenance, including regular cleaning of the water basin and media, is essential to prevent microbial growth and maintain hygienic conditions.

Practical Applications in Warehouses

Air washers are commonly installed as central units or modular devices in warehouses, production halls, packaging facilities, and large workshops. They are particularly valued not just for temperature control but for improving indoor air quality by reducing contaminants.

Conclusion

Air washers provide an economical, simple, and efficient evaporative cooling and air cleaning solution for industrial warehouse HVAC systems. By lowering air temperature, increasing humidity, and removing airborne particles, these devices create a more comfortable and healthier working environment. Correct selection and routine maintenance are key to ensuring the optimal performance of air washers.