Types of Condensers

Main Concept:

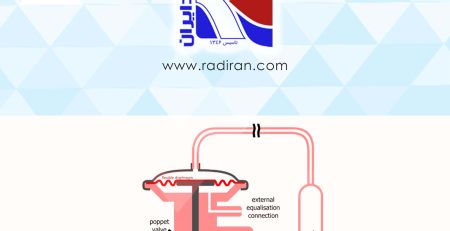

Condensers operate based on the principles of heat transfer, which involves the movement of heat from warmer environments to cooler ones. The functioning of a condenser involves three basic phases:

- Phase One: Desuperheating

-

- In this phase, the highly heated and pressurized refrigerant vapor entering the condenser first loses its heat. This process aids in the initial cooling of the refrigerant.

- Phase Two: Condensation

-

- Once sufficient heat has been removed from the refrigerant vapor, the condensation process begins. In this stage, the refrigerant, still in gas form, is converted into a liquid state.

- Phase Three: Sub-cooling

-

- In this final stage, the liquid refrigerant is further cooled to ensure that even with a temperature increase, it does not revert back to vapor. This process guarantees that the refrigerant returns at a low temperature.

Types of Condensers

There are four main types of condensers used in HVAC systems, each with a specific method for heat extraction:

- Direct-contact Condensers:

-

- In this type, hot gas mixes with cold liquid. This mixture facilitates direct heat exchange, converting vapor into liquid. Due to its high efficiency, this model is a popular cooling solution.

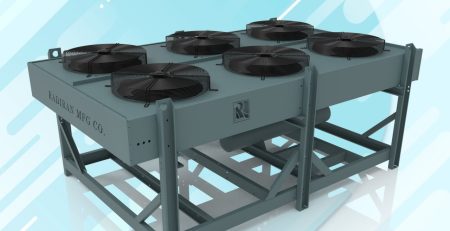

- Air-cooled Condensers:

-

- This type transfers the extracted heat to the outside air and is typically installed in household refrigerators and freezers for small commercial applications.

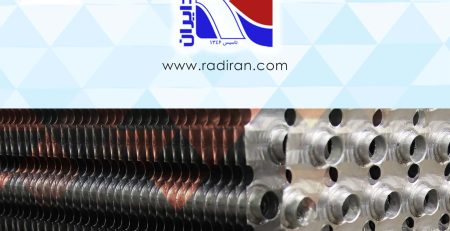

- Water-cooled Condensers:

-

- In this type, heat is extracted using flowing water. These condensers require a continuous water source and are generally used in larger industrial refrigeration systems.

- Evaporative Condensers:

-

- This type serves as a solution in situations where installing other types of condensers is not feasible. If there is insufficient water for a water-cooled condenser, an evaporative condenser can use air to extract heat from the system.