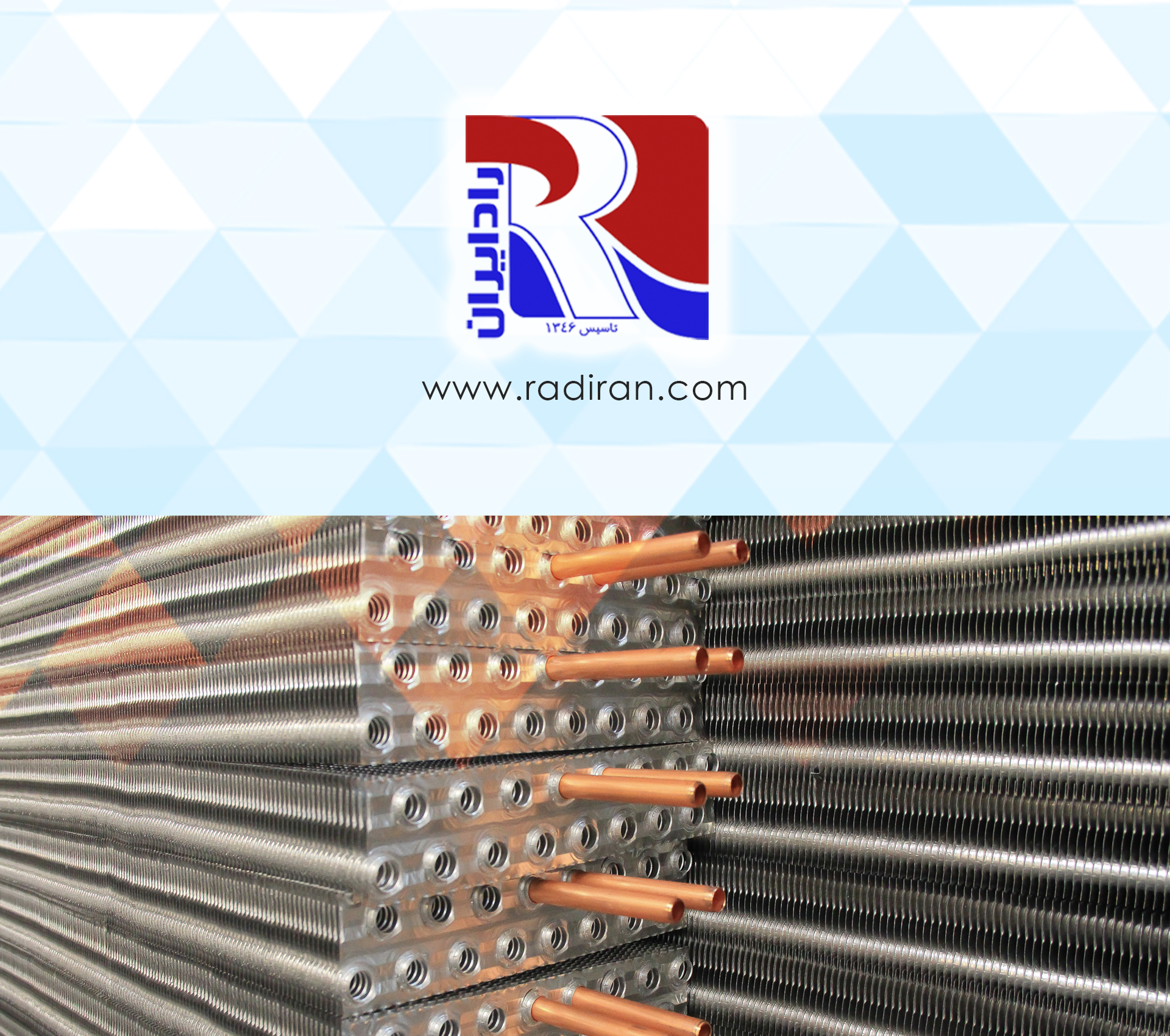

Tube Expansion Process for Bonding Copper Tubes to Aluminum Fins in Fin–Tube Coils

<p>

The tube expansion (expand) process used to bond copper tubes to aluminum fins in fin–tube coils is one of the critical manufacturing operations in heat exchanger production. The primary objective of this process is to create a stable mechanical and thermal contact between the tube and the fin such that thermal conductivity between the inner tube surface and fin surface is maximized, while ensuring sufficient mechanical strength and structural cyclic durability.

Process Steps and Methods

1. Alignment and Preparation

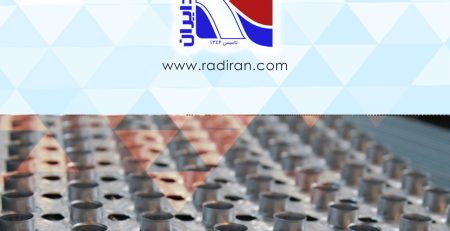

The copper tubes and fin assembly are first positioned on a fixture or holder. The fin collar openings must match the outer tube diameter precisely so that the fin stack remains in place during expansion. Proper alignment and gap control are vital to prevent asymmetric stresses during expansion.

2. Pre-cutting and Cleaning

Both the internal and external surfaces of the tubes and the fin edges are inspected and cleaned. The contact surfaces must be free of contaminants, oxides, or oil to ensure direct metal-to-metal bonding.

3. Mechanical or Hydraulic Expansion

Mechanical Expansion (Mandrel or Roller Type)

In mechanical expansion, a mandrel or adjustable roller tool is inserted into the tube. By applying radial force, the tool expands the tube outward, pressing it tightly against the fin collars.

Hydraulic Expansion

Hydraulic expansion uses internal hydrostatic pressure to expand the tube uniformly toward the fin surface. This method typically produces more uniform stress distribution and reduces the risk of tube cracking.

4. Parameter Control

Key process parameters include:

-

Degree of tube diameter increase (reported as a percentage or micrometers)

-

Extension rate

-

Expansion speed

-

Multi-stage expansion sequence

Expansion is often performed gradually in multiple stages to reduce residual stresses and prevent tube deformation or cracking.

5. Quality Inspection

After expansion, non-destructive tests (NDT) such as leak testing, pressure testing, and visual inspection are performed to ensure full contact between tube and fin and to detect any cracks or gaps. Additional evaluations may include measuring contact area and assessing thermal contact resistance.

Advantages and Justification for Using the Expansion Process

Optimal Thermal Conductivity

Proper expansion creates full surface contact between the copper tube and aluminum fin, enhancing heat transfer from the tube-side fluid to the fin and subsequently to the surrounding air.

Reduced Thermal Contact Resistance

Direct metal-to-metal bonding significantly reduces contact thermal resistance, increasing heat-exchanger performance.

Mechanical Integrity and Extended Service Life

A firm mechanical bond prevents relative motion between tube and fin, protecting the coil from vibration-induced fatigue and thermal cycling stress.

Reduced Leakage and Increased Pressure Reliability

When properly expanded and inspected, the likelihood of fluid leakage decreases, and the coil can safely operate under its designed pressure conditions.

Manufacturing Efficiency and Cost Effectiveness

Both mechanical and hydraulic expansion methods allow for mass production with high repeatability, reducing per-unit manufacturing cost.

Design Flexibility

The process supports the use of fins with various geometries and high fin densities without compromising thermal contact quality.

Summary

The copper-tube to aluminum-fin expansion process is a critical engineering operation that, when conducted with precise control over process parameters, can significantly enhance both the thermal performance and mechanical durability of fin–tube coils.