Shell and tube heat exchangers HEX

A shell and tube heat exchanger is a device used for transferring heat between two fluids, often liquids or gases that are at different temperatures. It consists of two main components: the shell and the tubes. In the upcoming paragraphs the different parts of the shell and tube HEX are explained in detail.

1. Shell: The shell is the outermost component and typically cylindrical in shape. It contains one fluid, known as the shell-side fluid. The shell is designed to withstand the pressure of this fluid. It often has inlet and outlet ports for the shell-side fluid. The shell could be made from carbon steel or stainless steel based on the application.

2. Tubes: Inside the shell, there is a bundle of tubes. These tubes contain the other fluid, known as the tube-side fluid. The tubes are responsible for facilitating the heat transfer between the two fluids. They are usually made of materials with good thermal conductivity such as Copper.

3. Tube Sheets: Tube sheets are plates that seal the ends of the tube bundle, ensuring that the tube-side fluid and shell-side fluid remain separate. Tube sheets are located at both ends of the shell and serve to support and secure the tubes in place.

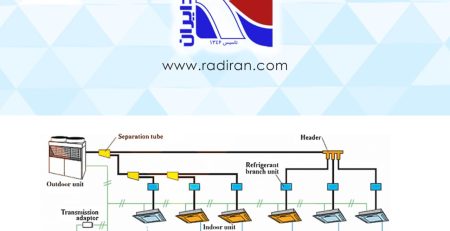

4. Baffles: Baffles are structures inside the shell that direct the flow of the shell-side fluid. They enhance the heat transfer efficiency by promoting turbulence in the fluid, which improves heat exchange. Baffles guide the shell side fluid across the tubes, preventing straight-through flow. This heightens the heat transfer efficiency by providing counter-current flow between shell-side and tube-side fluids.

5. Tube Passes: The tubes are often arranged in multiple passes within the shell. A single pass means the fluid travels through the tubes only once, while multiple passes involve the fluid making several passes through the tube bundle.

6. Tube Layout: Tubes can be arranged in various configurations, such as parallel, triangular, or square patterns, depending on the specific design requirements and heat transfer goals.

7. Tube Side and Shell Side: These terms refer to the two sides of the heat exchanger. The fluid inside the tubes is the tube-side fluid, while the fluid outside the tubes but inside the shell is the shell-side fluid.

In operation, one fluid passes through the tubes while the other flows over the tubes within the shell. Heat is exchanged through the tube walls, enabling the transfer of thermal energy from one fluid to the other. Shell and tube heat exchangers are widely used in various industries such as HVAC, refrigeration systems, chemical processes and etc. due to their efficiency, versatility, and ability to handle high-pressure applications.

Advantages and disadvantages

Shell and tube HEXs have efficient heat transfer due to their large surface area. Versatility in handling a wide range of temperatures and pressures is another advantage of these heat exchangers. On the other hand, complex design and construction, and more maintenance and initial cost could be counted as disadvantages of shell and tube heat exchangers.