Managing Fouling in Fin Tube Coil Exchangers

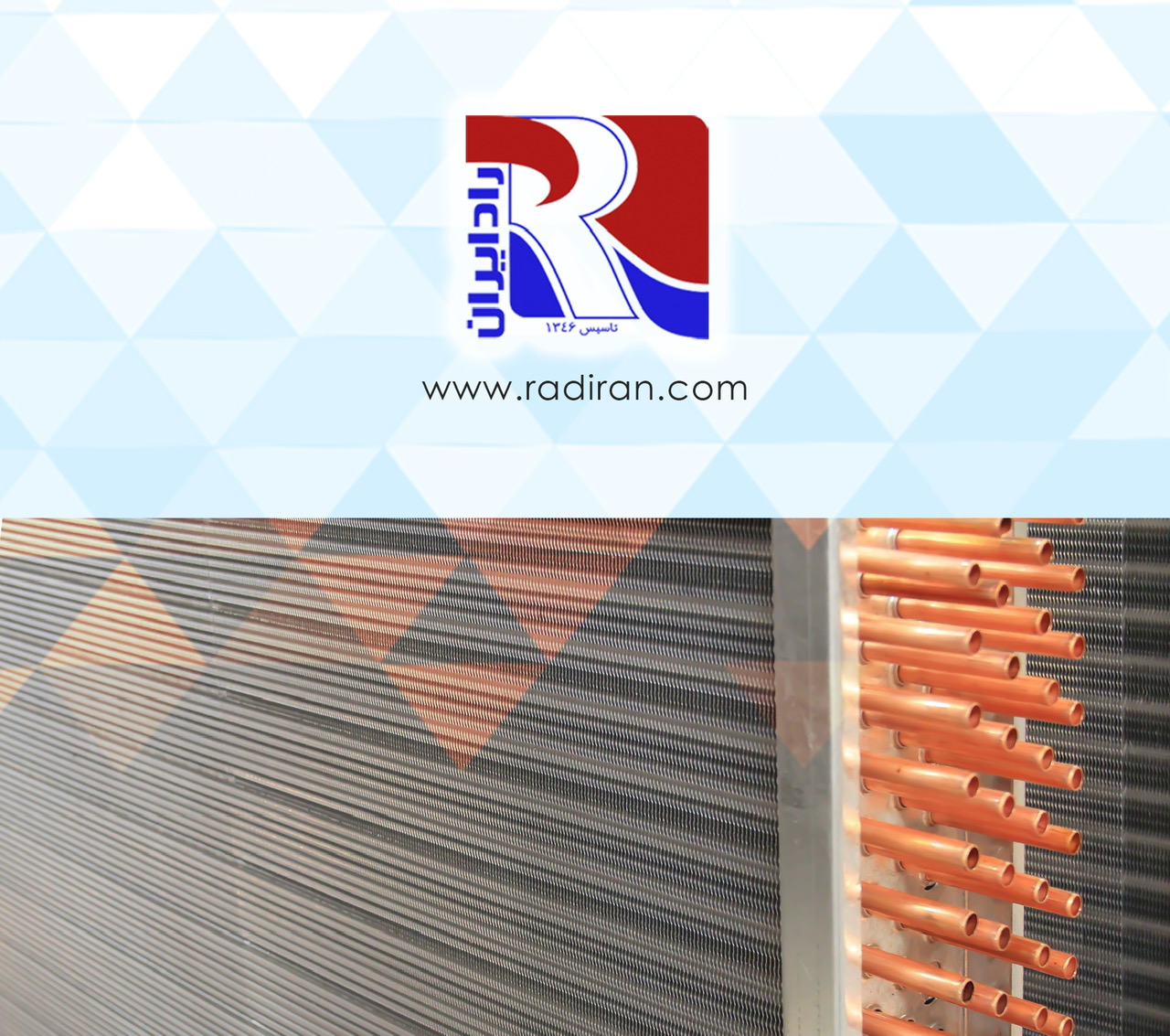

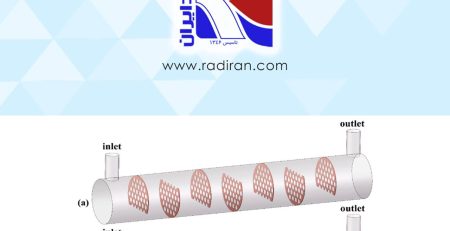

Fin tube coil exchangers are widely utilized in various industrial applications due to their efficiency and compact design. Despite their advantages, these systems are not immune to performance issues related to fouling. Fouling is a common problem that can significantly impact the efficiency and operational lifespan of heat exchangers.

What is Fouling?

Fouling refers to the accumulation of unwanted materials on the surfaces of the heat exchanger, particularly on the finned tubes. This accumulation can consist of scale, dirt, algae, or other contaminants that adhere to the heat transfer surfaces. As these deposits build up, they create an insulating layer that impedes the heat transfer process, leading to reduced efficiency and increased energy consumption. Additionally, fouling can cause pressure drops and result in frequent maintenance requirements.

Causes of Fouling

Several factors contribute to fouling in fin tube coil exchangers:

1. Fluid Quality: The presence of impurities or high mineral content in the fluids being processed can lead to scaling and deposition on the tube surfaces.

2. Temperature Variations: Fluctuating temperatures can exacerbate fouling by causing thermal stresses that promote the formation of scale and other deposits.

3. Fluid Composition: Fluids containing high levels of suspended solids or corrosive chemicals are more likely to contribute to fouling.

4. Flow Dynamics: Inadequate flow rates or turbulent flow conditions can enhance the deposition of fouling materials.

Managing Fouling

Effective management of fouling is essential to maintain the performance and extend the life of fin tube coil exchangers. Here are some strategies to manage fouling:

1. Routine Cleaning: Regular cleaning schedules help remove accumulated deposits before they become problematic. Cleaning methods can include chemical treatments, mechanical cleaning, or a combination of both, depending on the type of fouling and the design of the exchanger.

2. Water Treatment: Implementing water treatment solutions such as water softeners or scale inhibitors can prevent the formation of scale and other deposits. Ensuring that the fluid used in the system is of high quality is also crucial.

3. Optimized Operation Conditions: Maintaining stable operating conditions, including temperature and flow rates, can help minimize the conditions that lead to fouling. Proper system design to handle varying operational conditions can also reduce fouling risk.

4. Regular Monitoring: Continuous monitoring of the heat exchanger’s performance can help detect early signs of fouling. This proactive approach allows for timely interventions, such as adjustments in operation or additional cleaning, to prevent more severe fouling issues.

5. Material Selection: Using materials that are resistant to corrosion and fouling can enhance the durability of the heat exchanger. Specialized coatings and treatments can also be applied to reduce fouling and extend the life of the equipment.

In summary, while fouling is a common issue in fin tube coil exchangers, implementing effective management strategies can significantly mitigate its impact. Routine maintenance, appropriate water treatment, optimal operational conditions, and material selection are key to ensuring the efficient and reliable performance of these heat exchangers.