Evaporators and condensers design parameters

- Heat Transfer Efficiency: Both coils need to efficiently transfer heat. In the evaporator, heat absorption from the surroundings is essential for the refrigeration cycle, while in the condenser, heat rejection is critical.

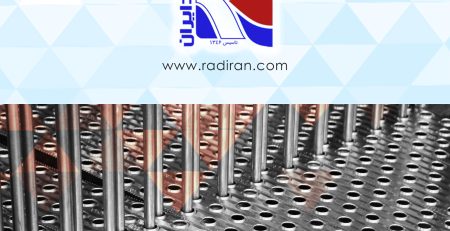

- Surface Area: Increasing the surface area of the coils enhances heat transfer. This is achieved through coil geometry and fin design. Fins on the coils increase the surface area, promoting better heat exchange.

- Refrigerant Flow: Proper refrigerant flow is essential for optimal heat transfer. Design considerations include the tube diameter, length, and arrangement, ensuring efficient refrigerant circulation.

- Material Selection: Coils are often made of metals like copper or aluminum due to their good thermal conductivity. The choice of material depends on factors like cost, compatibility with refrigerants, and corrosion resistance.

- Fouling and Corrosion Resistance: Coils are exposed to various environmental conditions. Resistance to fouling (accumulation of dirt and debris) and corrosion is crucial for maintaining long-term efficiency.

- Airflow: Adequate airflow over the coils is vital. In the evaporator, this ensures efficient heat absorption, while in the condenser, it helps dissipate heat. Proper spacing and arrangement of fins are considered for optimal airflow.

- Pressure Drop: The design should minimize pressure drop across the coils to maintain efficient refrigerant flow and system performance.

- Tube and Fin Design: Tube and fin configurations impact heat transfer. For example, microchannel coils with smaller tubes and enhanced fin designs can provide higher efficiency and compact designs.

- Temperature and Pressure Ratings: Coils must withstand the temperature and pressure conditions specific to their application

- Environmental Regulations: Compliance with environmental regulations may dictate the type of refrigerants used and influence coil design to optimize efficiency and minimize environmental impact.

Consideration of these factors ensures that evaporator and condenser coils are designed to maximize efficiency, durability, and overall performance in various applications.