Quality control in coils

Quality control in coils involves various tests to ensure product integrity. Common tests include:

1. Dimensional Checks: Verifying coil dimensions to meet specified tolerances ensures consistency and accurate manufacturing.

2. Surface Inspection: Examining the coil surface for defects like scratches, dents, or irregularities ensures a smooth, defect-free appearance.

3. Coating Thickness Measurement: For coated coils like galvanized steel, checking the thickness of the protective layer ensures adherence to quality standards.

4. Tensile Strength Testing: Evaluating the coil’s tensile strength ensures it meets mechanical strength requirements for its intended application.

5. Impact Resistance Test: Assessing the coil’s ability to withstand impact helps determine its durability and resistance to damage during handling or use.

6. Chemical Composition Analysis: Ensuring the correct chemical composition of the coil material is crucial for meeting performance standards and application requirements.

7. Corrosion Resistance Testing: Particularly relevant for galvanized steel, testing its resistance to corrosion ensures long-term durability in various environments.

8. Bend Test: Assessing the coil’s flexibility and resistance to cracking during bending helps ensure suitability for specific applications.

9. Hardness Testing: Measuring the hardness of the coil material provides insights into its strength and suitability for specific industrial uses.

10. Weight Measurement: Verifying the weight of coils ensures they meet specified standards and assists in controlling material usage.

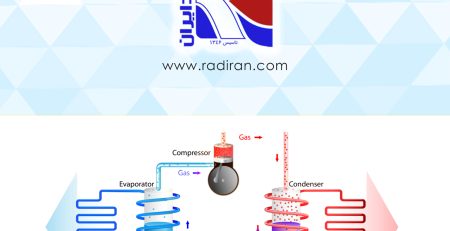

11. Leakage Testing: This involves pressurizing the coil with gas and checking for any signs of leaks. It ensures that the coil maintains its integrity and prevents gas escape.

12. Pressure Drop Test: This test assesses the pressure drop within the coil under specified conditions. It helps ensure that the coil can maintain the required pressure levels without significant loss.

By implementing these quality control tests, manufacturers can deliver coils that meet or exceed industry standards, providing customers with reliable and high-quality products.