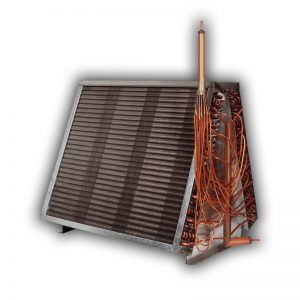

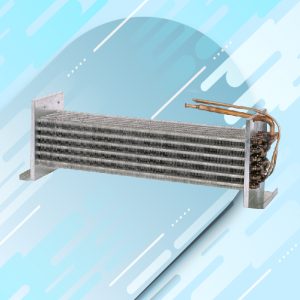

Refrigeration evaporator unit

Radiran evaporators are produced and supplied in capacities ranging from 2.4 kW to 120 kW for various applications, utilizing the highest quality materials and European standard components.

Coil:

The use of turbo coils for refrigerant systems with Inner Grooved tubes ensures maximum efficiency and heat exchange, given their minimal thickness and internal grooves. The aluminum fins produced utilize the latest technology, featuring specific grooves (turbulence) and sinusoidal waves, which optimize efficiency and reduce defrosting time. The ability to produce evaporators with fin spacing ranging from 1.6 mm to 12 mm is one of the characteristics of this company’s products.

- Hot Gas Defrosting:

Very rapid and uniform frosting removal is achieved using hot gas discharged from the compressor. - Electrical Defrosting:

In this method, high-quality stainless steel elements resistant to corrosion are used.

The fans used in Radiran’s evaporators are from reputable European brands such as ZIEHL-ABEGG, Rosenberg, and ebm papst, and they are available in sizes of 35 cm, 40 cm, 50 cm, 63 cm, and 80 cm. They are equipped with overload and temperature protection systems (thermistor) and feature an external rotor structure with an IP54 protective system and an electrical box with an IP55 protective system.

Evaporator Body Material:

Depending on their applications, they are made from aluminum or galvanized steel with an electrostatic powder coating, providing resistance against damage from corrosion and oxidation while also offering an attractive appearance.

Refrigerant:

Compatible with the following refrigerants:

(R404A, R134A, R22, …)

Secondary refrigerants (glycol, etc.)

- Description

Description

For Order, Design and Installation, Please Contact to Radiran Production Department.