Compression Chiller

A compression chiller is a type of refrigeration system used for cooling large spaces, such as commercial buildings, industrial facilities, or data centers. It employs a compression cycle to remove heat from a specified area and reject it elsewhere. The main components of a compression chiller include:

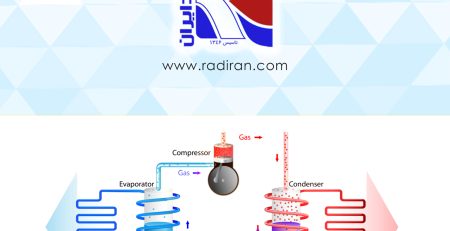

1. Compressor: – The compressor is a crucial component that pressurizes and circulates the refrigerant within the system. It increases the temperature and pressure of the refrigerant, turning it into a high-energy, high-temperature gas.

2. Condenser: – The high-temperature, high-pressure refrigerant gas flows to the condenser, where it releases heat to the surroundings. This causes the refrigerant to change from a gas to a liquid state. The condenser is typically a heat exchanger located outside the building.

3. Expansion Valve: – The liquid refrigerant then passes through an expansion valve or an expansion device. This valve reduces the pressure of the refrigerant, causing it to expand rapidly. As a result, the temperature of the refrigerant drops significantly.

4. Evaporator: – The low-pressure, low-temperature refrigerant liquid now enters the evaporator, which is often located inside the building near the area to be cooled. Heat from the building’s interior is absorbed by the refrigerant, causing it to evaporate and turn back into a low-pressure gas.

5. Refrigerant: – Refrigerants play a crucial role in the compression chiller’s operation. These substances have a low boiling point and can easily change between liquid and gaseous states, enabling them to absorb and release heat efficiently.

6. Control System: – The control system manages the operation of the compression chiller, regulating factors such as temperature, pressure, and flow rates. Modern chillers often incorporate advanced control systems for optimal efficiency and performance.

7. Heat Exchangers: – Heat exchangers are essential components for transferring heat between the refrigerant and the fluid to be cooled. The evaporator and condenser act as heat exchangers, facilitating the exchange of heat with the surroundings or the building’s interior.

8. Shell and Tube Heat Exchanger:

– Commonly used in large compression chillers, this type of heat exchanger consists of tubes through which the refrigerant flows, surrounded by a shell through which the cooling water circulates. This design enhances heat transfer efficiency. Understanding these components and their interactions provides insight into the operation of compression chillers, which are widely employed for efficient and effective cooling in various industrial and commercial applications.