Comparition of Fin Tube Coils and Shell and Tube Heat Exchangers

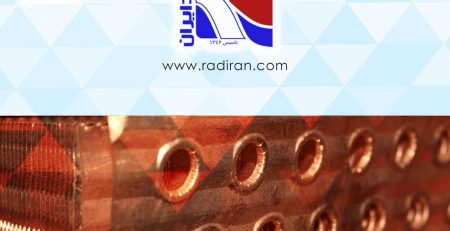

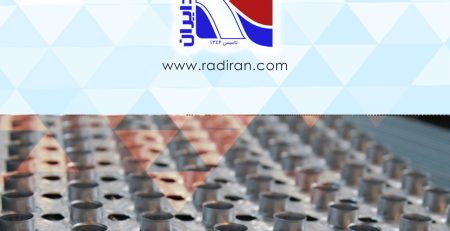

Fin Tube Coils:

1. Application: Fin tube coils are commonly used in systems where air needs to be heated or cooled. This can include applications like air conditioning units, refrigeration systems, or HVAC (Heating, Ventilation, and Air Conditioning) systems.

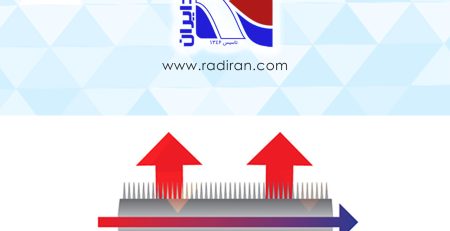

2. Design: These coils consist of tubes with extended surfaces or fins. The fins increase the surface area of the tubes, promoting better heat transfer between the fluid (usually air) inside the tubes and the surrounding environment.

3. Efficiency: The increased surface area provided by the fins enhances the efficiency of heat transfer. This design is effective for applications where compactness and efficiency in air-based heat exchange are crucial.

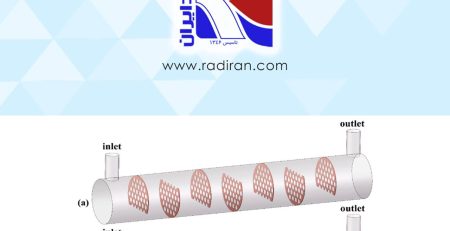

Shell and Tube Heat Exchangers:

1. Application: Shell and tube heat exchangers are versatile and find applications in various industries, including chemical processing, power generation, oil refineries, and more. They are suitable for exchanging heat between fluids, often in high-pressure and high-temperature environments.

2. Design: This type of heat exchanger consists of a bundle of tubes enclosed in a shell. One fluid flows through the tubes (tube side), and another fluid flows over the tubes within the shell (shell side). This design allows efficient heat transfer between the two fluids.

3. Versatility: Shell and tube heat exchangers can handle a wide range of fluids, making them suitable for diverse industrial processes. They are preferred when dealing with fluids that may contain impurities or when precise control over temperature is required.

In summary, the choice between fin tube coils and shell and tube heat exchangers depends on the specific requirements of the application. Fin tube coils are more focused on air-based systems with a compact design, while shell and tube heat exchangers offer versatility for a broader range of fluid-based applications, especially in industrial settings with demanding conditions.