The Importance of Expansion Valve in Refrigeration and Cooling Systems

The Importance of Expansion Valve in Refrigeration and Cooling Systems

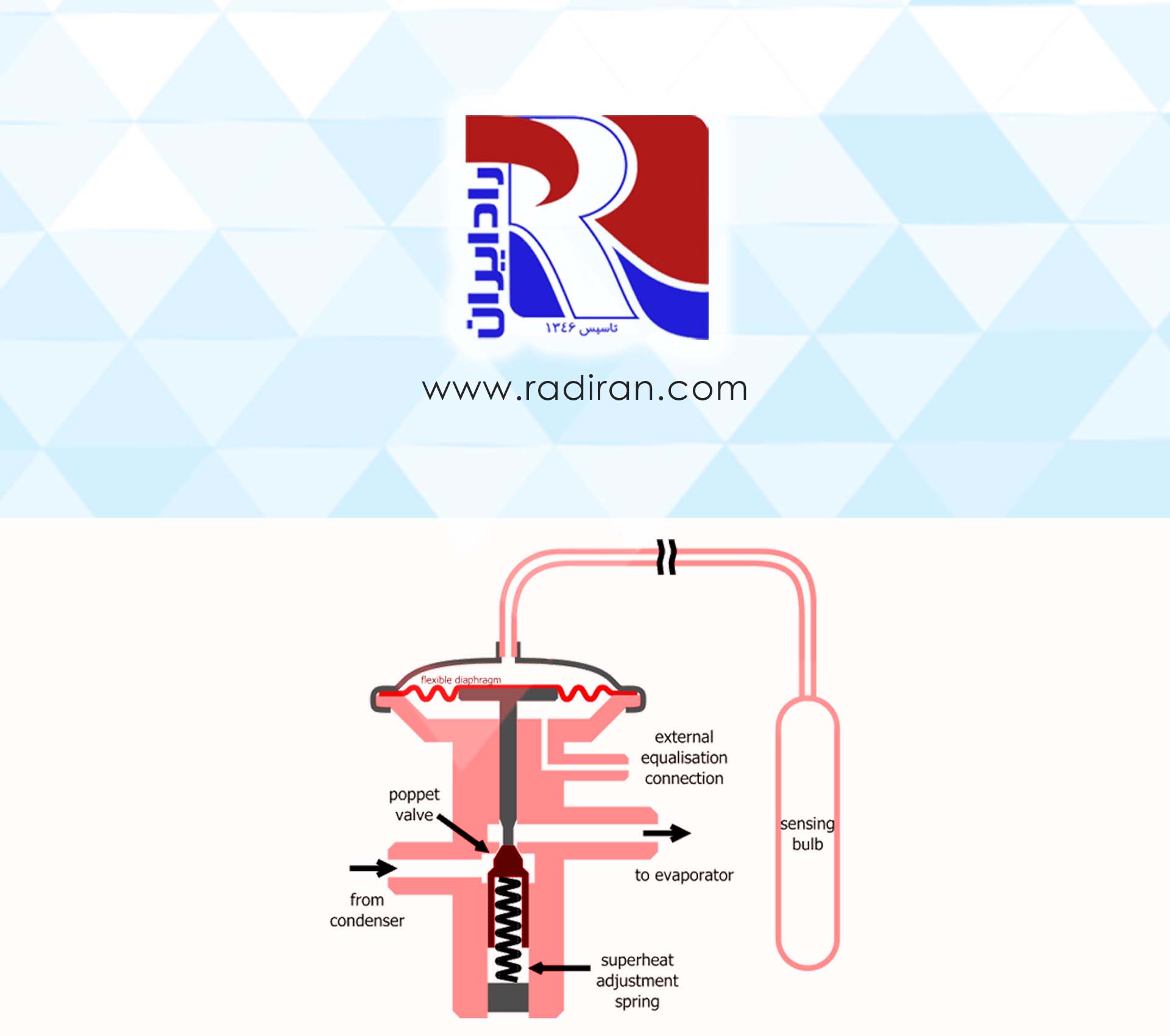

The expansion valve serves as a key component in refrigeration and cooling systems, playing a crucial role in optimizing system performance, controlling precise temperature and pressure, and ensuring energy efficiency. These valves regulate the flow of refrigerant to the evaporator, enabling maximum efficiency of the system.

Types of Expansion Valves

Expansion valves can be categorized into different types, each designed for specific applications. The most common types include:

1. Thermostatic Expansion Valves (TEV): These valves use a temperature sensor to monitor the refrigerant temperature in the evaporator and adjust the refrigerant flow based on the measured value.

2. Electronic Expansion Valves (EEV): Utilizing an electronic circuit, these valves can precisely control the refrigerant flow according to the system’s needs.

3. Thermal Expansion Valves: This type employs a thermal sensor that measures the ambient temperature and adjusts the refrigerant flow accordingly.

Each of these systems enhances efficiency and reduces energy consumption in refrigeration processes. Regular servicing and maintenance of expansion valves, especially to prevent failures and disruptions in the performance of refrigeration systems, is essential.

Application of Expansion Valves in Chillers

In chiller systems, the expansion valve acts as a control component of high significance. Typically placed in the refrigerant flow path between the evaporator and condenser, it regulates the refrigerant flow using a diaphragm or valve.

Types of Expansion Valves in Chillers

1. Thermostatic Expansion Valve (TEV): Capable of controlling the refrigerant flow based on the evaporator temperature, it opens the valve when the temperature reaches a specified threshold.

2. Electronic Expansion Valve (EEV): Utilizes an electronic controller to adjust the refrigerant flow based on temperature and pressure data from the system.

Given their vital function, these valves require regular maintenance and servicing to ensure the optimal and correct operation of the chiller system.

Mechanism of Expansion Valve Failures

As a crucial component in refrigeration systems, a failure of the expansion valve can jeopardize the overall performance of the system. Some common issues include:

1. Clogging of the Expansion Valve: This issue can arise from the entry of foreign particles, moisture, or the use of inappropriate refrigerants, leading to reduced cooling capacity.

2. Leakage of the Expansion Valve: Leakage could be due to the failure of internal components like the diaphragm or valve, resulting in refrigerant loss and diminished system effectiveness.

3. Overall Failure of the Expansion Valve: This may occur due to overuse, improper installation, or the use of low-quality valves.

4. Freezing of the Expansion Valve: This condition may occur particularly in humid and cold environments, where ice formation around the expansion valve can block the valve and reduce or stop the refrigerant flow.

The presence of these issues can disrupt the refrigeration process and diminish the quality of the equipment. Therefore, continuous monitoring and maintenance of expansion valves are crucial in preventing such disruptions.