Investigation of Air Flow on Fins of Fin and Tube Coils in Condensers

Introduction

When I think about what makes a condenser truly effective, I always find myself zeroing in on those intricate fin and tube coils. They’re not just passive elements; their performance directly hinges on how air moves around them—especially across the fins. Airflow and heat exchange are tightly linked here, and getting the flow right can make a world of difference in energy savings and system reliability.

The Role of Fins and Tubes

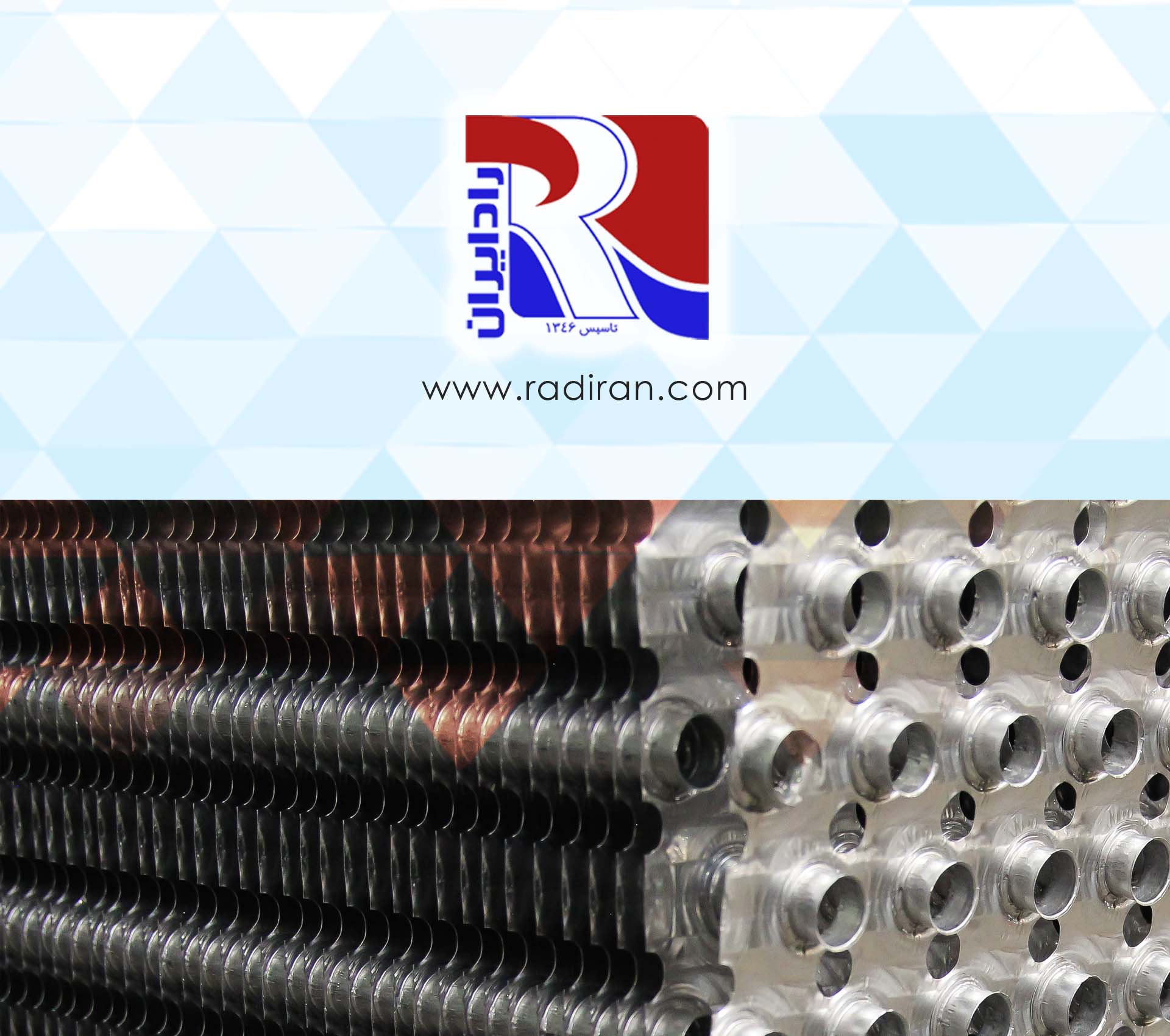

Fin and tube coils are the heart of many condensers found in refrigeration and air conditioning. The tubes circulate refrigerant, while the fins significantly boost the heat transfer area. The effectiveness of the heat transfer depends heavily on the air’s ability to interact with as much of that fin surface as possible.

- Fins: These increase the total surface area, improving thermal exchange between the coil and the passing air.

- Tubes: Refrigerant moves through these, releasing heat as air sweeps past the extended fin surfaces.

Factors Affecting Air Flow Around Fins

As an engineer, I know that the actual movement of air through fins isn’t always perfect—there’s resistance, turbulence, and geometric complexity. The following factors are key:

- Fin spacing: Too close together, and airflow becomes blocked by dust and debris; too far, and you lose thermal contact.

- Fin shape and geometry: Wavy or louvered fins can disrupt the flow and promote more heat exchange—at the cost of higher pressure drops.

- Air velocity: The faster the air, the better the heat transfer, but excessive speeds can lead to noise and diminishing returns.

Experimental and Computational Investigations

I love that this field has room for both hands-on experiments and computer-aided simulation. Some common approaches:

- Wind tunnel testing: Physical coils are exposed to controlled airflow, and key parameters like temperature drop and airflow resistance are measured.

- CFD (Computational Fluid Dynamics): These simulations give me a powerful way to visualize how air navigates the maze of fins—highlighting dead zones, recirculation, or hot spots.

- Field observations: Sometimes there’s no substitute for real-world performance data, especially in cluttered plant environments.

Performance Optimization Strategies

Fine-tuning airflow isn’t just about cranking up the fan. Here’s what typically grabs my attention:

- Cleaning and maintenance: Even small amounts of dust or ice can choke off air pathways, dramatically degrading coil performance.

- Redesigning fin profiles: Aerodynamically inspired fins can push the heat transfer up a notch without demanding much more fan power.

- Variable-speed fans: Matching air velocity to load conditions can improve efficiency and reduce wear—and my ears appreciate the quieter operation too.

Conclusion

Optimizing air flow on the fins of fin and tube coils isn’t just a matter for academic study—it’s a practical concern with big implications for efficiency, reliability, and operating costs. As I keep learning, I realize there’s a sweet spot to be found between maximizing surface exposure and letting air flow as freely as possible. A holistic approach, considering layout, maintenance, and intelligent control, is the key to unlocking top performance from any condenser setup.