Subcooling in fin tube heat exchangers

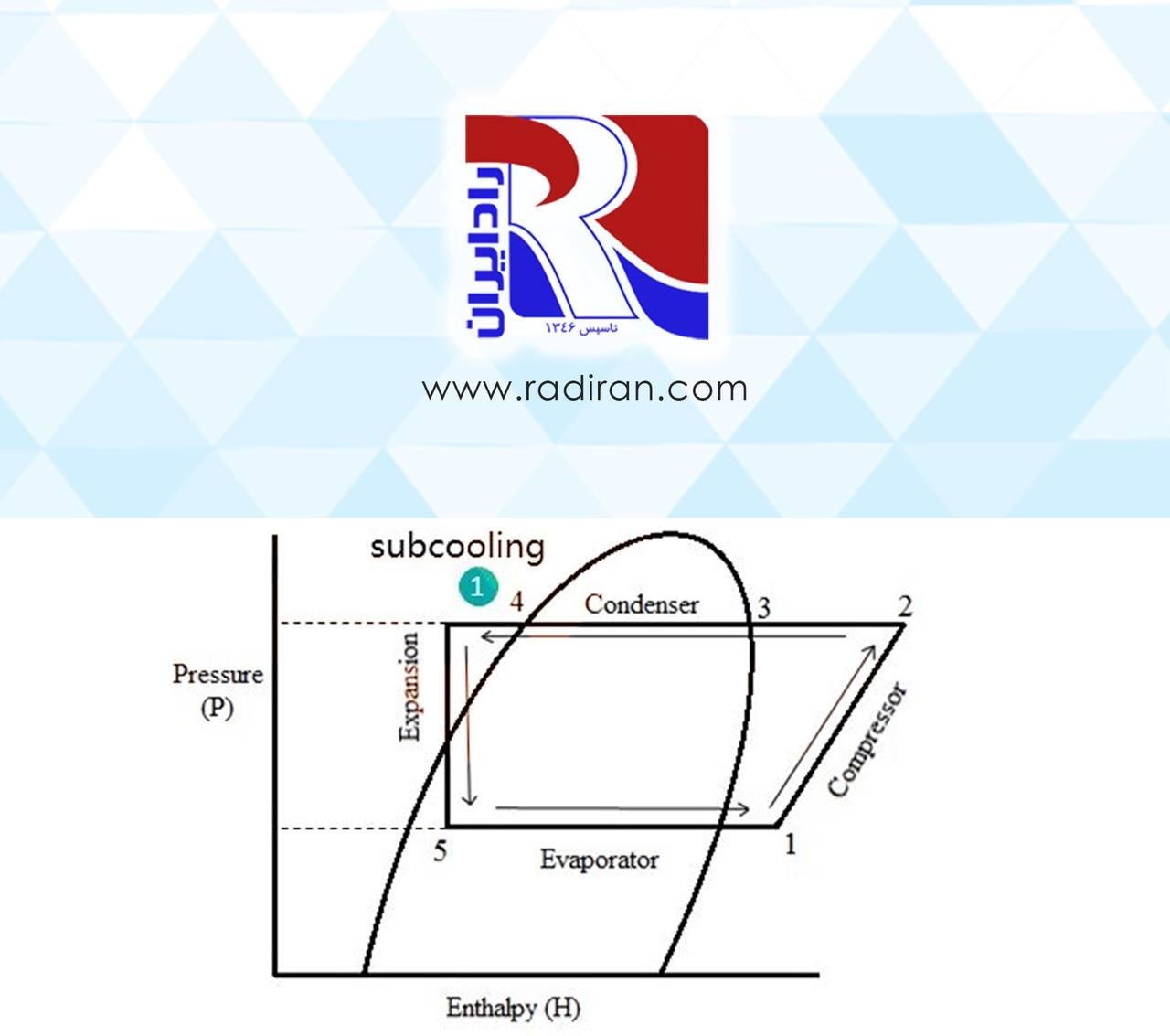

Subcooling in fin tube heat exchangers is a refrigeration process that involves lowering the temperature of the liquid refrigerant below its saturation point at a given pressure. This is typically achieved by removing additional heat from the refrigerant after it has undergone the condensation process. In fin tube heat exchangers, subcooling is often applied to the liquid refrigerant before it enters the expansion device or the evaporator.

Process of Subcooling in Fin Tube Heat Exchangers:

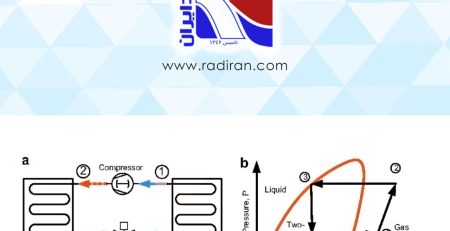

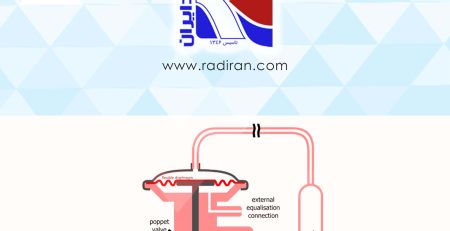

- Condensation: The refrigerant undergoes condensation in the condenser, transitioning from a vapor to a liquid state by releasing heat to the surrounding environment.

- Subcooling: After condensation, the liquid refrigerant is further cooled below its saturation temperature. This is the subcooling process, where additional heat is removed, ensuring that the refrigerant remains in a liquid state.

Advantages of Subcooling in Fin Tube Heat Exchangers:

- Enhanced Heat Transfer Efficiency: Subcooling improves the efficiency of heat transfer in the evaporator by ensuring that the refrigerant entering the expansion device is in a subcooled liquid state. This enhances the overall performance of the heat exchanger.

- Prevention of Flash Gas Formation: Subcooling helps prevent the formation of flash gas, which occurs when liquid refrigerant evaporates prematurely in the expansion device. This is crucial for maintaining the stability of the refrigeration system and preventing issues like compressor damage.

- Increased System Capacity: By subcooling the refrigerant, the system can absorb more heat, leading to increased cooling or refrigeration capacity. This is beneficial in applications where higher cooling loads are required.

Disadvantages of Subcooling in Fin Tube Heat Exchangers:

- Energy Consumption: The process of subcooling requires additional energy input to cool the refrigerant below its saturation point. This can result in increased energy consumption, impacting the overall energy efficiency of the system.

- Complexity and Cost: Implementing subcooling in a fin tube heat exchanger system may introduce complexity and additional costs. Specialized components, controls, and monitoring systems may be necessary, increasing both initial and maintenance expenses.

- Potential for Overcooling: If subcooling is