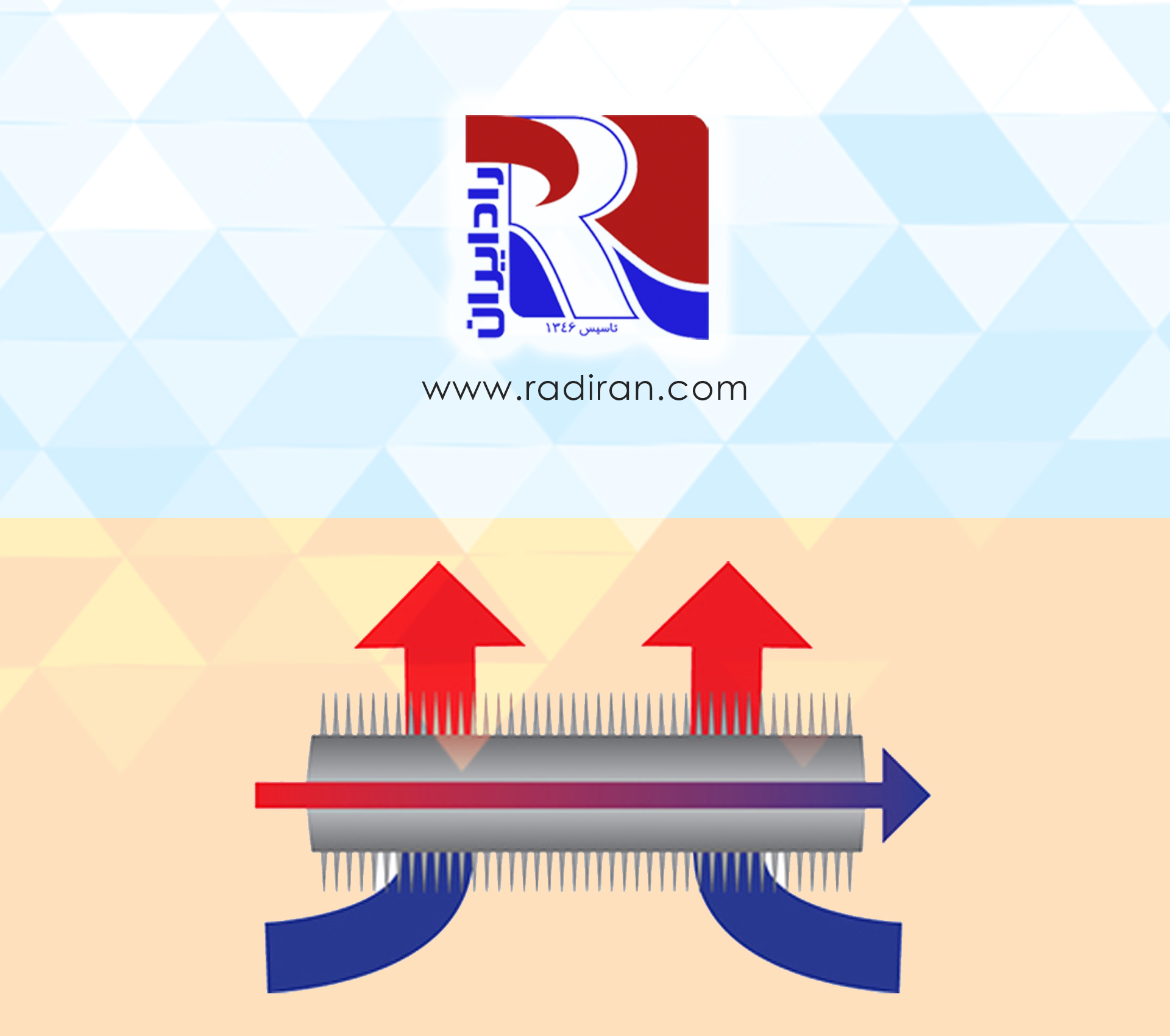

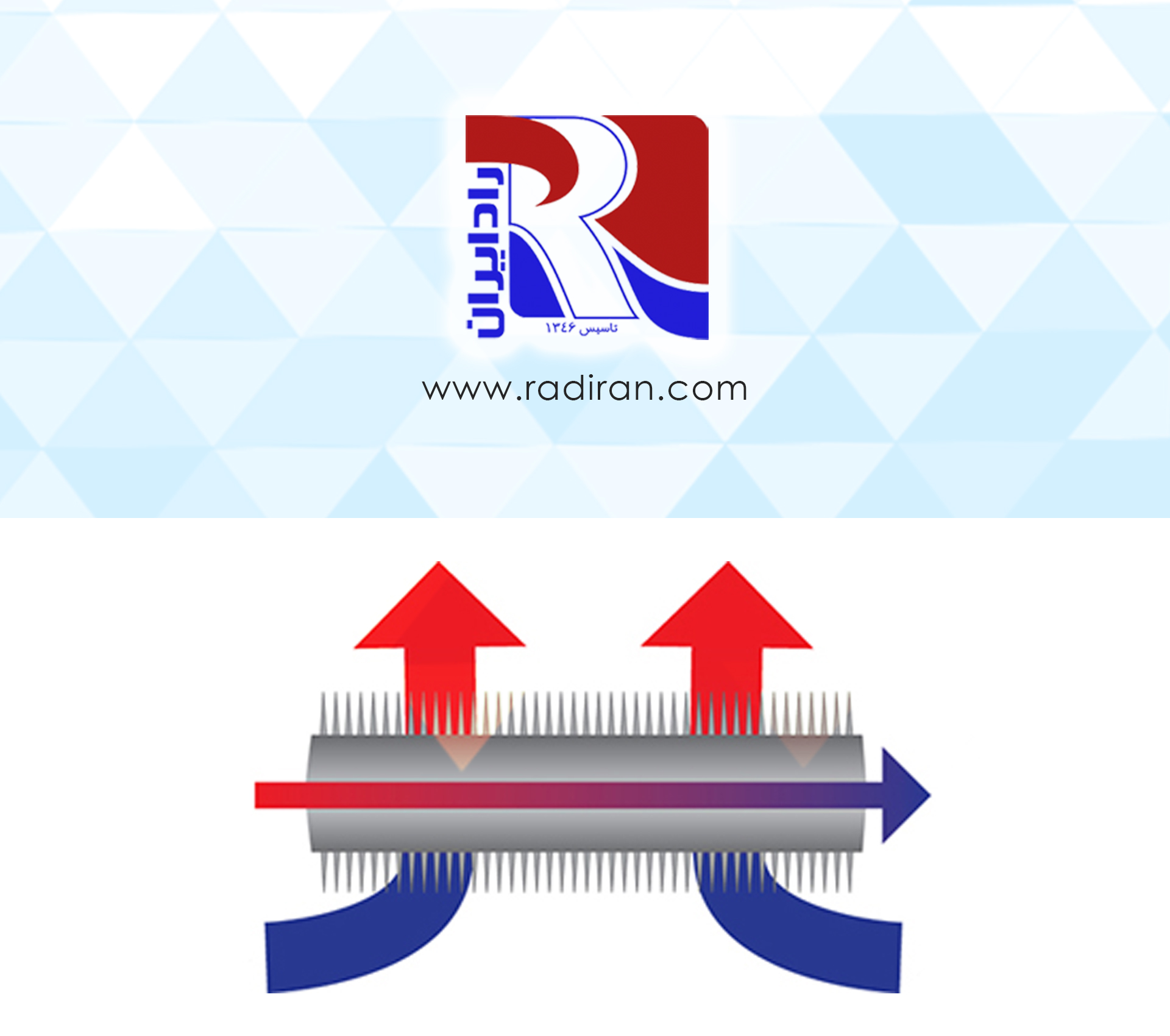

The Impact of Internal Grooves in Copper Tubes on Heat Transfer in Fin-Tube Coils

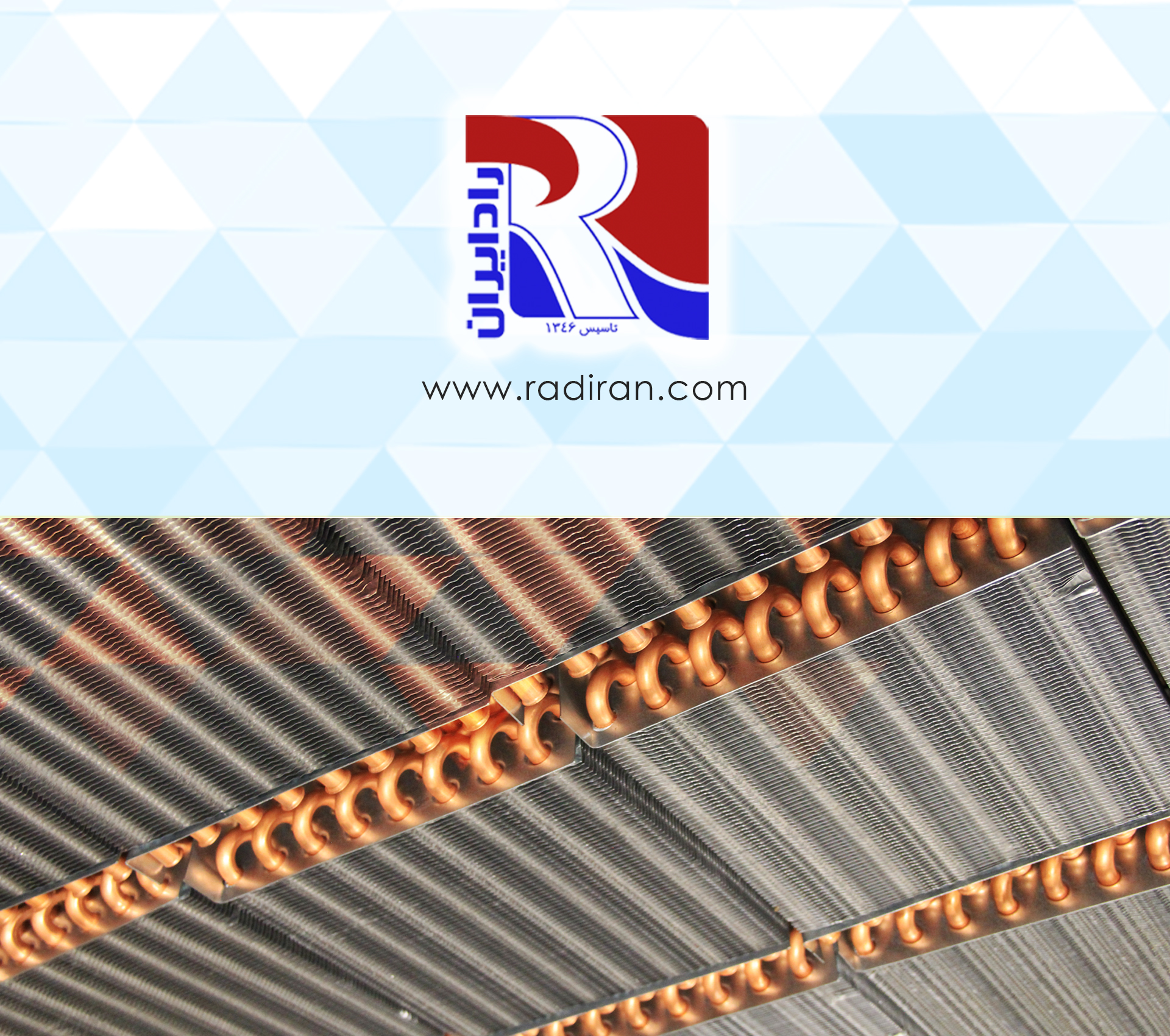

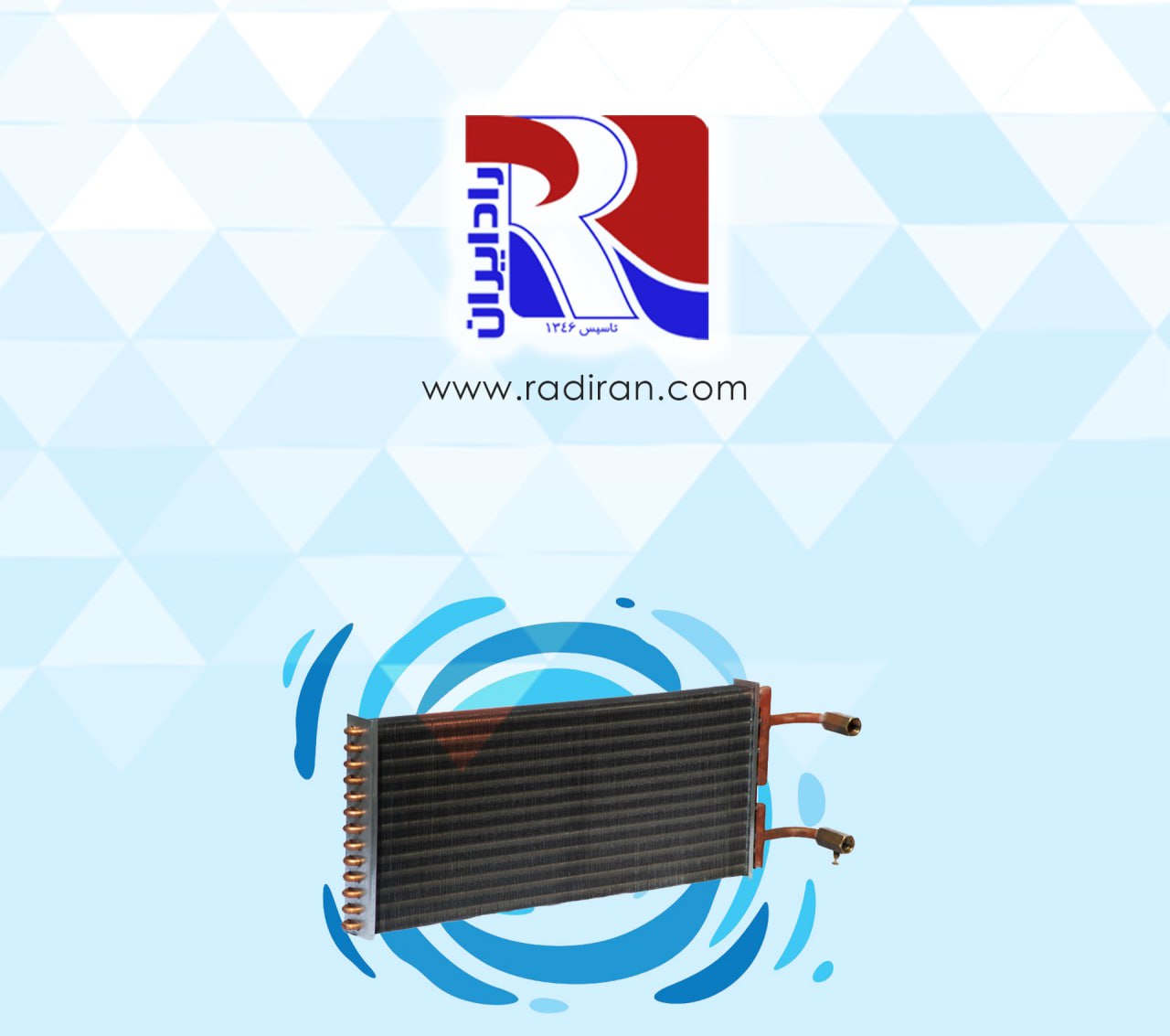

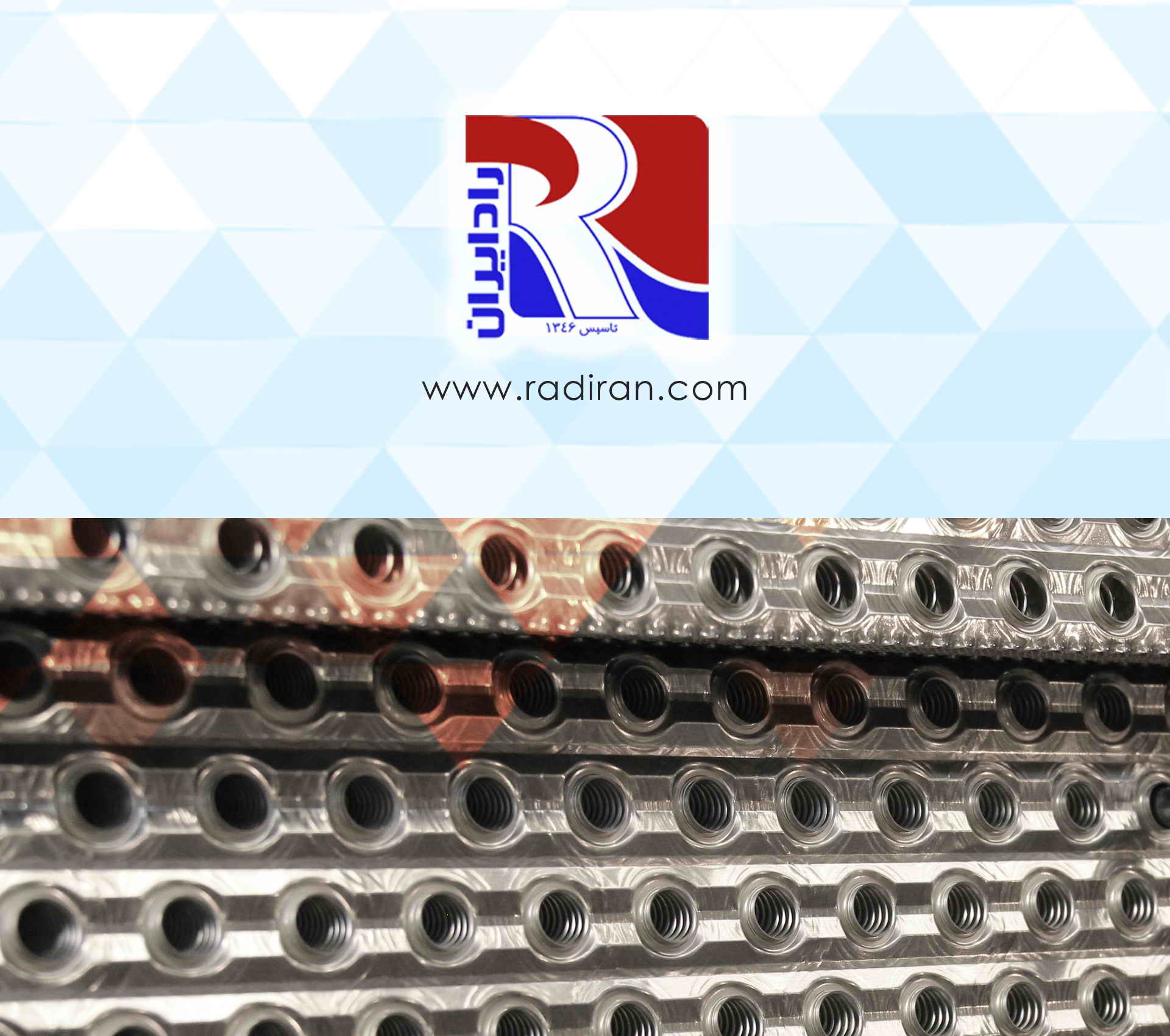

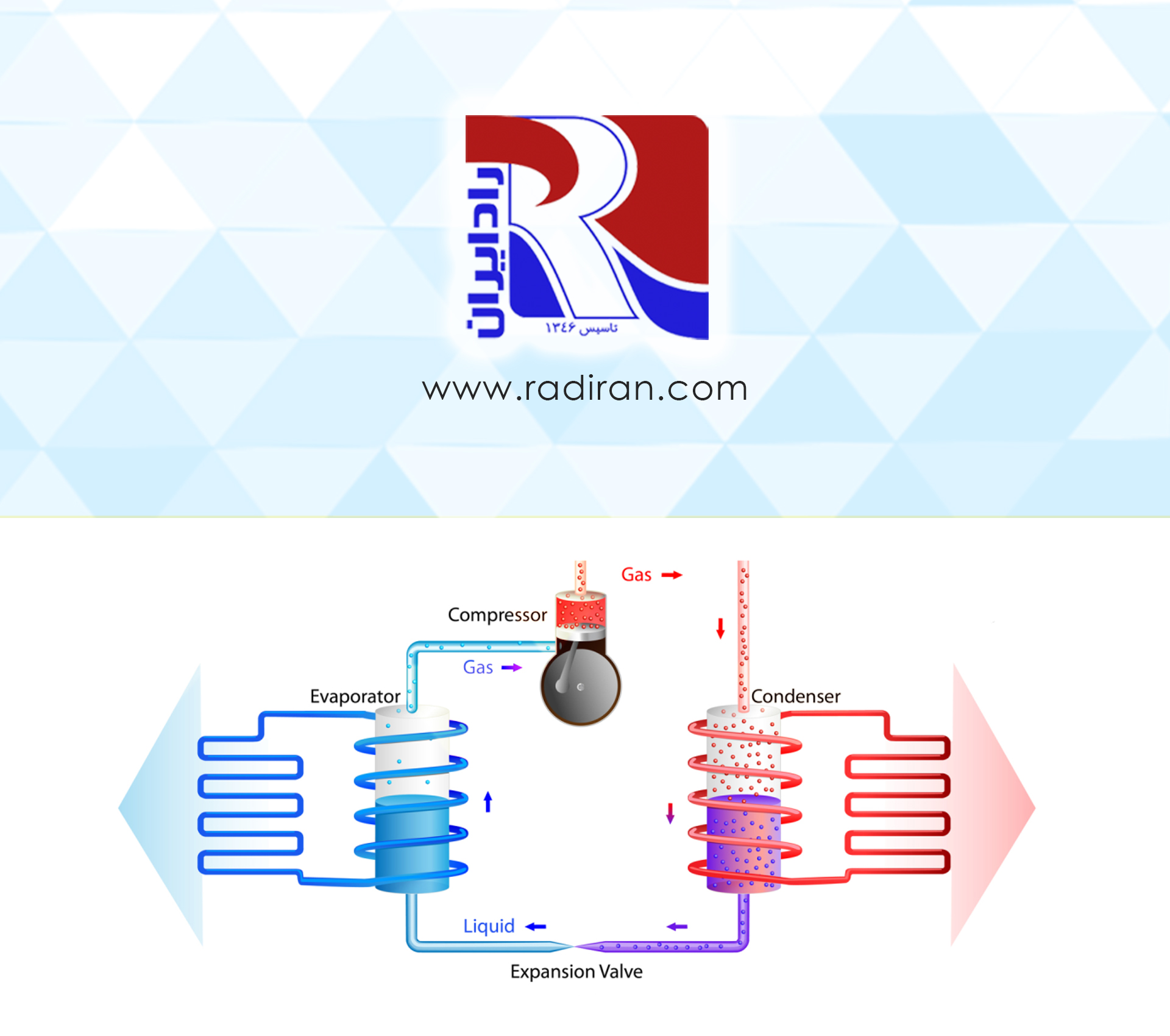

<p> Introduction Heat transfer plays a crucial role in thermal and cooling systems. Copper tubes used in fin-tube coils are highly favored due to copper's superior heat transfer properties. However, the design and physical characteristics of these tubes, particularly their internal grooves, can significantly affect their efficiency. Internal Grooves in Tubes Internal grooves in tubes can take the form of longitudinal or circular indentations. These grooves increase the contact surface area between the fluid and the tube wall, subsequently enhancing heat transfer. By...