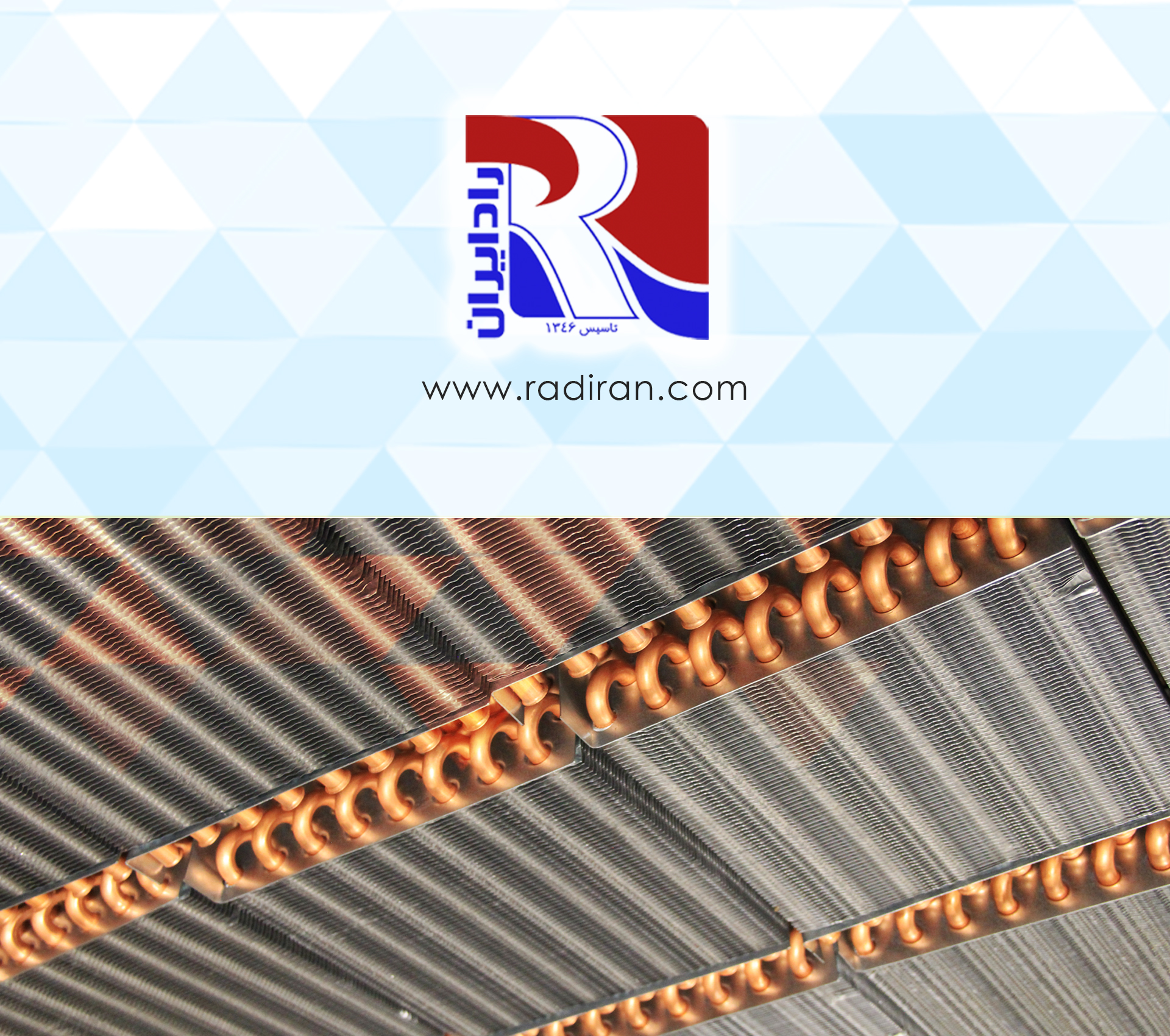

Corrosion in Fin–Tube Coils and Methods for Preventing It

Fin–tube coils, which typically combine aluminum fins with copper tubes, are widely used in air-conditioning and HVAC systems. Corrosion in these components leads to reduced heat-transfer performance, efficiency loss, leakage, and shortened service life. The following sections present practical, preventive engineering methods for protecting these coils.

Material Selection and Proper Design

Corrosion-Resistant Alloys

Selecting aluminum and copper alloys with inherently high corrosion resistance—such as surface-treated aluminum alloys or copper alloys with controlled alloying elements—forms the foundational approach to durability improvement.

Hydrophilic Design and Proper Drainage

Coils should be designed to minimize water retention and moisture accumulation between fins and on tube surfaces (e.g., proper slope angles, drainage channels). This reduces localized corrosion risks.

Avoiding Dissimilar-Metal Contact

Direct contact between copper and aluminum can result in galvanic (electrochemical) corrosion. Using non-metallic interfaces or protective coatings at contact points helps prevent such degradation.

Surface Coatings and Treatments

Anodic and Cathodic Protective Coatings

Applying protective industrial coatings—such as moisture-resistant varnishes, specialized HVAC coil coatings, or electrostatic coatings—creates a barrier between the environment and the metal.

Thin Organic and Inorganic Films

Epoxy, polyurethane, or silane-based coatings protect surfaces from direct exposure to moisture and contaminants.

Hydrophobic Polymers on Fins

Hydrophobic finishes reduce water adhesion and droplet retention on fin surfaces, lowering the contact duration between water and metal, and mitigating localized corrosion.

Operational Environment Control

Humidity and Contaminant Management

Install air filters and pre-filtration systems to remove salts, sulfur compounds, SO₂, and other corrosive airborne pollutants. In marine environments, airborne salts are a major corrosion driver.

Temperature Control and Defrost Cycling

Proper defrost-cycle design helps avoid repetitive wet–dry cycling, which accelerates corrosion rates.

Cathodic Protection and pH Management (for Water-Side Systems)

Cathodic Protection

In water-side applications (e.g., condenser/evaporator coils involving water circulation), sacrificial anodes or impressed-current systems can be used to inhibit corrosion.

Water Chemistry Control

Proper control of pH, hardness, and scaling tendencies, combined with corrosion inhibitors and antifoam additives, reduces internal degradation. Maintaining chloride and sulfate ions within safe limits is essential.

Proper Installation and Maintenance

Stress-Free Installation

Mechanical stresses or improper contact between fins and tubes can damage protective coatings and create corrosion initiation points.

Periodic Inspection and Preventive Maintenance

Routine inspections should be conducted to identify darkened areas, deposit stains, or pitting indications. Metal-thickness measurements and electrochemical tests (e.g., EIS or corrosion-rate measurements) help detect early signs of deterioration.

Regular Cleaning

Dust, salt, and deposits should be removed using mild mechanical cleaning or controlled washing. Cleaning agents must be compatible with both coatings and base metals.

Localized Repair and Remedial Actions

Coating Repair (Patching)

Any scratches or coating damage must be repaired promptly using compatible coating systems to prevent corrosion spread.

Copper Surface Passivation

Passivating agents or controlled oxidative treatment can be used to form a protective oxide layer on copper surfaces.

Conclusion

Mitigating corrosion in fin–tube coils (aluminum fins with copper tubes) requires an integrated strategy: proper material selection and engineering design, use of surface coatings and protective treatments, environmental control, water-chemistry management in water-side systems, and structured installation and maintenance programs. Combined with timely inspection and repair, these measures significantly extend coil service life and maintain the thermal-exchange performance of HVAC systems.