Technical Guide for Sizing Inlet and Outlet Manifolds of Water-Fin–Tube Coils

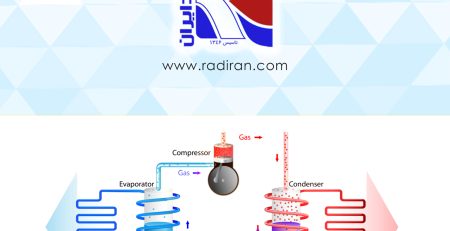

General Principles

Primary Objective:

To ensure uniform water distribution across all tube circuits, minimize pressure drop, and prevent cavitation and noise.

Key Parameters:

Total system mass flow rate m˙\dot{m}, number of tube rows NtN_t, internal tube diameter dtd_t, effective coil length LL, desired velocity in each tube, and allowable total pressure drop in the manifolds.

Fundamental Calculations

1. Determining Total Flow Rate

Use the coil heat load QQ and water temperature difference ΔT\Delta T:

m˙=QcpΔT\dot{m} = \frac{Q}{c_p \Delta T}

where cpc_p, the specific heat capacity of water, is approximately

4180 J/(kg\cdotpK).4180 \; \text{J/(kg·K)}.

2. Flow in Each Circuit (Tube Group Fed by One Manifold)

If the manifold divides each row into nn branches, the flow rate per branch is:

m˙branch=m˙n\dot{m}_{branch} = \frac{\dot{m}}{n}

3. Determining Manifold Diameter Based on Reynolds Criteria and Allowed Velocity

For flow inside a manifold, typical design velocity is:

0.3 to 1.5 m/s0.3 \text{ to } 1.5 \; \text{m/s}

(higher velocities increase noise and pressure loss).

The internal diameter DcD_c is calculated using:

Dc=4m˙πρvD_c = \sqrt{\frac{4\dot{m}}{\pi \rho v}}

where

ρ≈1000 kg/m3\rho \approx 1000 \; \text{kg/m}^3 (density of water)

and vv is the selected flow velocity.

Pressure Drop and Flow Distribution

1. Pressure Drop in the Manifold

Total pressure loss includes frictional losses along the length (Fanning/Darcy) and local losses at fittings and branches.

Using the Darcy–Weisbach equation:

ΔP=fLDcρv22\Delta P = f \frac{L}{D_c} \frac{\rho v^2}{2}

where ff is the friction factor (obtained from Moody chart or Colebrook/Haaland correlations).

2. Branch Losses

For each branch, calculate the branch loss coefficient kbranchk_{branch}:

ΔPbranch=kbranchρv22\Delta P_{branch} = k_{branch} \frac{\rho v^2}{2}

Design requirement:

Total pressure drop in the manifold should not exceed a certain fraction of the system’s total allowable pressure loss (typically 10–20%) to preserve hydraulic balance.

Branch Geometry and Achieving Uniform Flow Distribution

-

Use angled or beveled branch connections (rather than sharp T-joints) to reduce vortices and local losses.

-

Provide a straight inlet section of at least 5–10 times the manifold diameter before the first branch to allow flow development.

-

To achieve uniform distribution among circuits, branch diameters must be selected such that the pressure drop across all paths is nearly equal.

Balancing methods include:-

Adjusting branch lengths

-

Installing symmetric balancing valves

-

Practical Recommendations

-

For small to medium coils, manifold velocities of 0.5–1.0 m/s are generally suitable; for larger systems, lower velocities (0.3–0.6 m/s) are recommended.

-

Select appropriate manifold material and wall thickness to prevent corrosion and vibration (copper, stainless steel, or coated steel piping).

-

In detailed design, use hydraulic simulation software or piping network solvers (EPANET-like tools or dedicated HVAC calculators) to analyze flow distribution and pressure losses.

-

Always include a safety margin in sizing, and provide space for balancing valves and gauges for testing and commissioning.

By following these guidelines, you can optimally size inlet and outlet manifolds, ensure uniform flow distribution, and minimize pressure drop and operational noise.

If you provide numerical system values (heat load QQ, ΔT\Delta T, tube count, tube dimensions, coil geometry), I can perform a complete sample calculation and recommend exact manifold diameters.