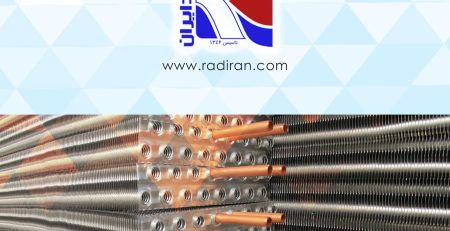

VARIOUS SHAPE OF COPPER TUBE

The shape of copper tubes in a heat exchanger can significantly impact its performance. Here are a few effects of various tube shapes:

- Inner Grooves: Tubes with inner grooves increase the surface area available for heat transfer. This design enhances the efficiency of heat exchange by promoting better contact between the fluid inside the tube and the tube wall. The increased surface area allows for more effective heat transfer, making the heat exchanger more efficient.

- Coiled Tubes: Coils provide flexibility and compactness, making them suitable for applications with space constraints. The coiled shape allows for a longer tube length within a confined space, promoting better heat transfer. Coils are often used in applications where compact design and efficient heat exchange are crucial, such as in HVAC systems.

- Straight Lengths: Straight tubes are versatile and commonly used in various heat exchanger designs. They are easy to manufacture and install, making them suitable for applications where simplicity and cost-effectiveness are priorities.

The choice of tube shape in a heat exchanger depends on factors such as the specific application, space constraints, and the desired level of heat transfer efficiency. Engineers select tube shapes based on these considerations to optimize the overall performance of the heat exchanger for its intended purpose.