Hybrid Cooling Towers — Technology Review, Advantages, and Applications

<p>

Abstract

Hybrid cooling towers, as an advanced generation of cooling systems, integrate both dry and wet cooling methods. This technology reduces water consumption and increases energy efficiency while addressing the environmental challenges associated with traditional cooling systems. This article provides a comprehensive review of the technical principles, structure, performance, advantages, disadvantages, and application areas of hybrid cooling towers.

Introduction

Across various industries, cooling systems play a crucial role in maintaining optimal equipment performance and process stability. Cooling towers are generally classified into two main categories: wet and dry systems, each with its own advantages and limitations. The hybrid cooling tower concept was developed to combine the strengths of both systems—reducing water consumption while offering improved efficiency and operational flexibility.

Fundamentals and Operating Principles of Hybrid Cooling Towers

Wet Cooling (Evaporative Cooling)

In wet cooling, warm air comes into direct contact with water, promoting evaporation and reducing the water temperature. Although this method offers high thermal performance, it involves significant water consumption and may generate suspended water droplets (drift).

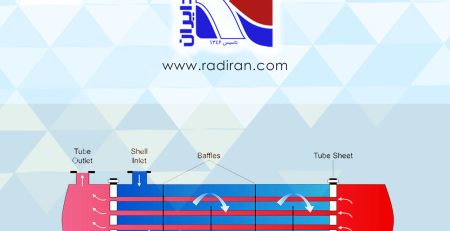

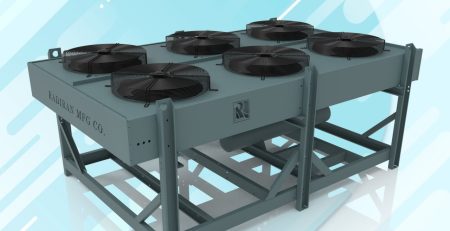

Dry Cooling (Air Cooling / Sensible Cooling)

In this method, heat transfer occurs through metallic surfaces (such as heat exchangers) without direct contact between air and water. Water consumption is nearly zero; however, cooling effectiveness is lower and energy costs are higher compared to wet cooling.

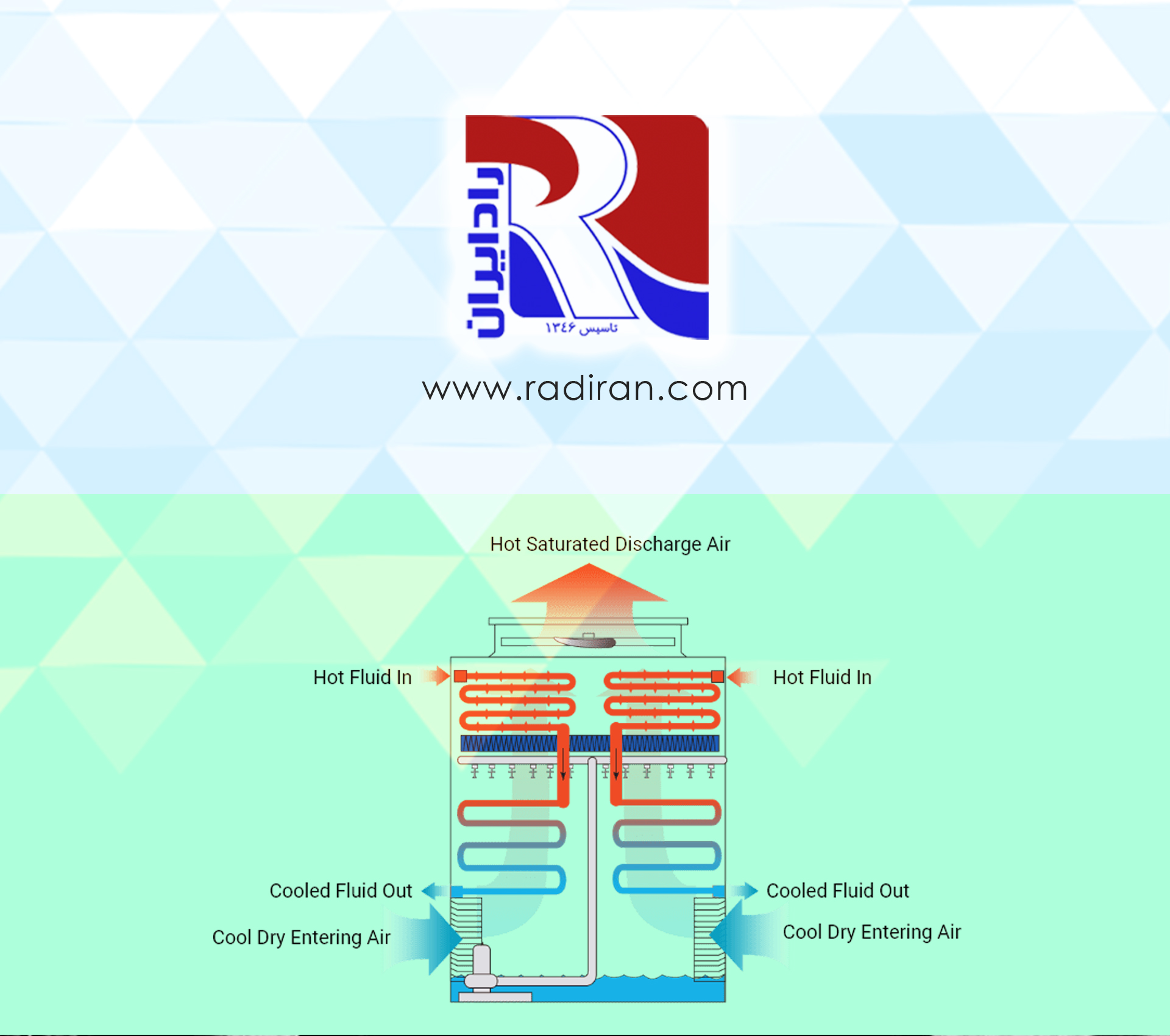

Structure of a Hybrid Cooling Tower

A hybrid cooling tower integrates a dry heat-exchange section and a wet evaporative section within a single unit. Typically, water first passes through the dry section for pre-cooling and then enters the wet section for final cooling. This configuration optimizes both water and energy consumption by reducing the thermal load on the evaporative stage.

Advantages

Reduced Water Consumption

Compared to conventional wet cooling towers, hybrid systems dramatically decrease water usage.

Operational Flexibility

Depending on ambient conditions (temperature and humidity), the system can operate in dry, wet, or hybrid mode.

Lower Environmental Impact

Reduced drift emission and decreased use of anti-scaling and water-treatment chemicals.

Extended Equipment Life

Lower corrosion and scaling rates relative to purely wet cooling systems.

Improved Energy Efficiency

Enhanced system performance due to load reduction on the wet section.

Disadvantages and Challenges

-

Higher initial capital cost compared to traditional cooling towers

-

Increased design complexity and the need for more sophisticated control to coordinate dry and wet sections

-

Requirement for more specialized maintenance

Applications

Hybrid cooling towers are widely used in power plants, refineries, petrochemical facilities, and large commercial or industrial buildings where optimal water management is essential. In arid and semi-arid regions, this technology plays a critical role in water-resource conservation.

Conclusion

By synergizing wet and dry cooling methods, hybrid cooling towers provide an effective solution for addressing water-resource limitations and environmental constraints. While their higher upfront cost and increased design complexity present challenges, their long-term advantages in sustainability and energy performance make them a justifiable and valuable choice for modern cooling applications.