Cold rooms according to their size

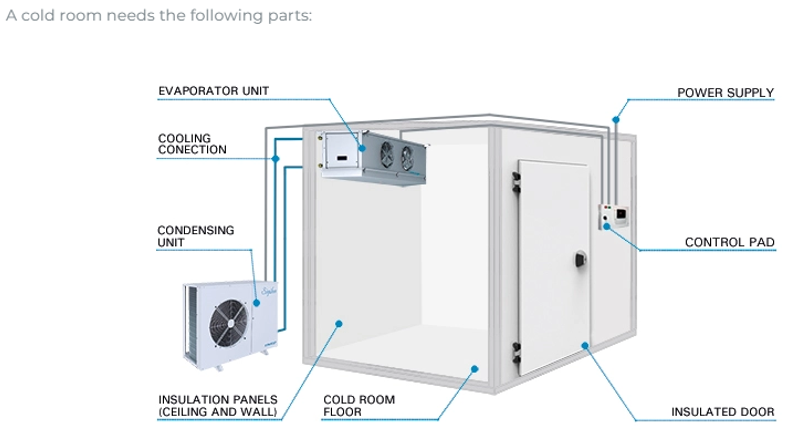

- Panels, floors and roofs, usually made of sandwich panels. The sandwich panel is composed of two steel sheets protecting an insulating core of high density polyurethane. This panel is responsible for the most efficient and durable cooling of the cold room.

- Airtight door. It can be sliding or pivoting, and incorporate an air curtain, or louvres to mitigate cold losses with each door opening.

- Humidifiers or dehumidifiers. These allow humidity (relative humidity) to be added to or removed from the cold room in such a way that it adapts to the best preservation conditions for the stored product.

- Cooling or freezing equipment. The choice of refrigeration unit is essential for the good preservation of the product. It may be monoblock or split system:

- A monoblock refrigeration unit is one in which the condenser and evaporator are in one unit.

- A split refrigeration system that consists of two units, the condensing unit separated from the evaporator. The installation of this type of system is more complex, but it allows the selection of the type of evaporator that best adapts to the optimum preservation conditions for each product and expels the hot air from the room where the cold room is located.

- Ventilation and air extraction system.

- Locked man alarm.

- Gas leakage alarm system.

How not to make a mistake when you choose a refrigeration unit?

INTARCON has the system Calcooling, a software developed to calculate the refrigeration needs of a cold room and select the refrigeration equipment, where by introducing certain parameters according to the type of cold room (modular, refrigerated cabinet, display cabinet, building site…), type of insulation and size, the refrigeration calculator indicates the appropriate equipment..

In addition to indicating the type of cold room, the refrigeration calculator knows the standard conservation parameters for all types of products (meat, vegetables, cereals, dairy products, fruit, pharmaceutical products, bread, wine, seafood…), and allows you to enter the number of door openings, daily air renewals, external humidity or even the product load in the cold room. With all this data, the tool gives us the refrigeration needs of that chamber, in other words, the refrigeration power you need to conserve the product optimally.

With these technical requirements, and taking into account the regulations for the installation of refrigeration equipment, we can choose the ideal equipment for the cold room.