Dry coolers

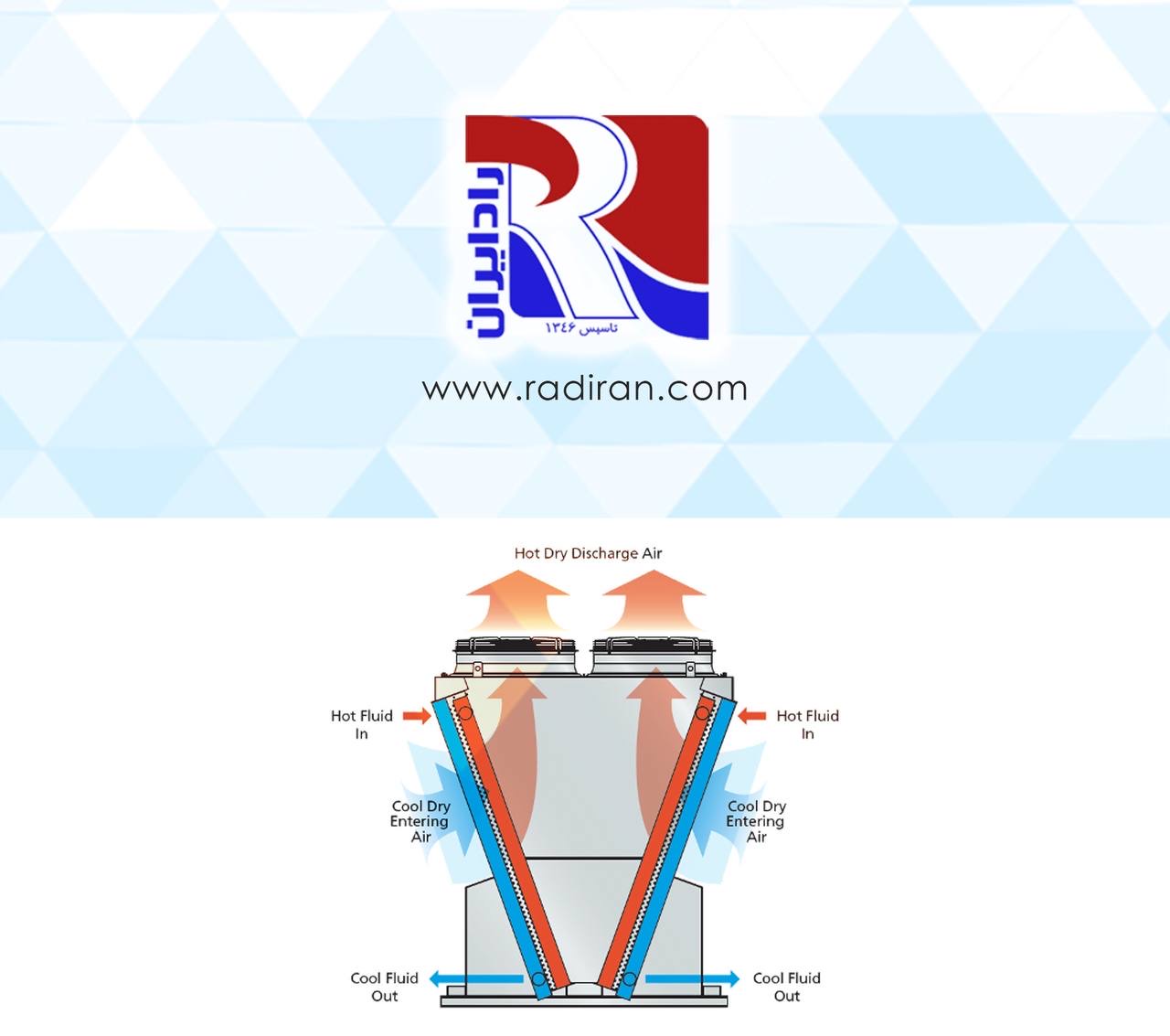

Dry coolers are heat exchangers used in industrial processes and HVAC systems, transferring heat from a fluid to ambient air without water evaporation. Coils, typically made of copper or aluminum, play a crucial role in this heat exchange process. They facilitate efficient heat dissipation, allowing dry coolers to operate in a closed-loop system without continuous water replenishment.

The coil design, including finned surfaces, enhances heat transfer, making dry coolers effective in various applications. Their compact footprint and maintenance-friendly features contribute to their efficiency and suitability for water-conscious or space-limited environments. Unlike traditional cooling towers that rely on water evaporation, dry coolers operate in a closed-loop system. This closed-loop design, made possible by the coils, eliminates the need for continuous water replenishment. It’s a significant advantage, especially in regions facing water scarcity or environmental regulations concerning water usage.

The coils’ design also influences the compactness of dry coolers. Their ability to dissipate heat effectively within a relatively small footprint is beneficial in applications where space is limited, such as industrial facilities.

Maintenance considerations are essential in ensuring the longevity and reliability of dry coolers. The coils’ accessibility and design features, like removable fan assemblies, play a role in simplifying maintenance tasks, minimizing downtime, and contributing to the overall efficiency of the system.

In summary, dry coolers and the coils within them provide an efficient and water-conserving alternative for heat dissipation in various industrial and HVAC applications. Their closed-loop design, material choices, and compact configurations make them a practical choice for environments where water usage is a concern or where space is at a premium.