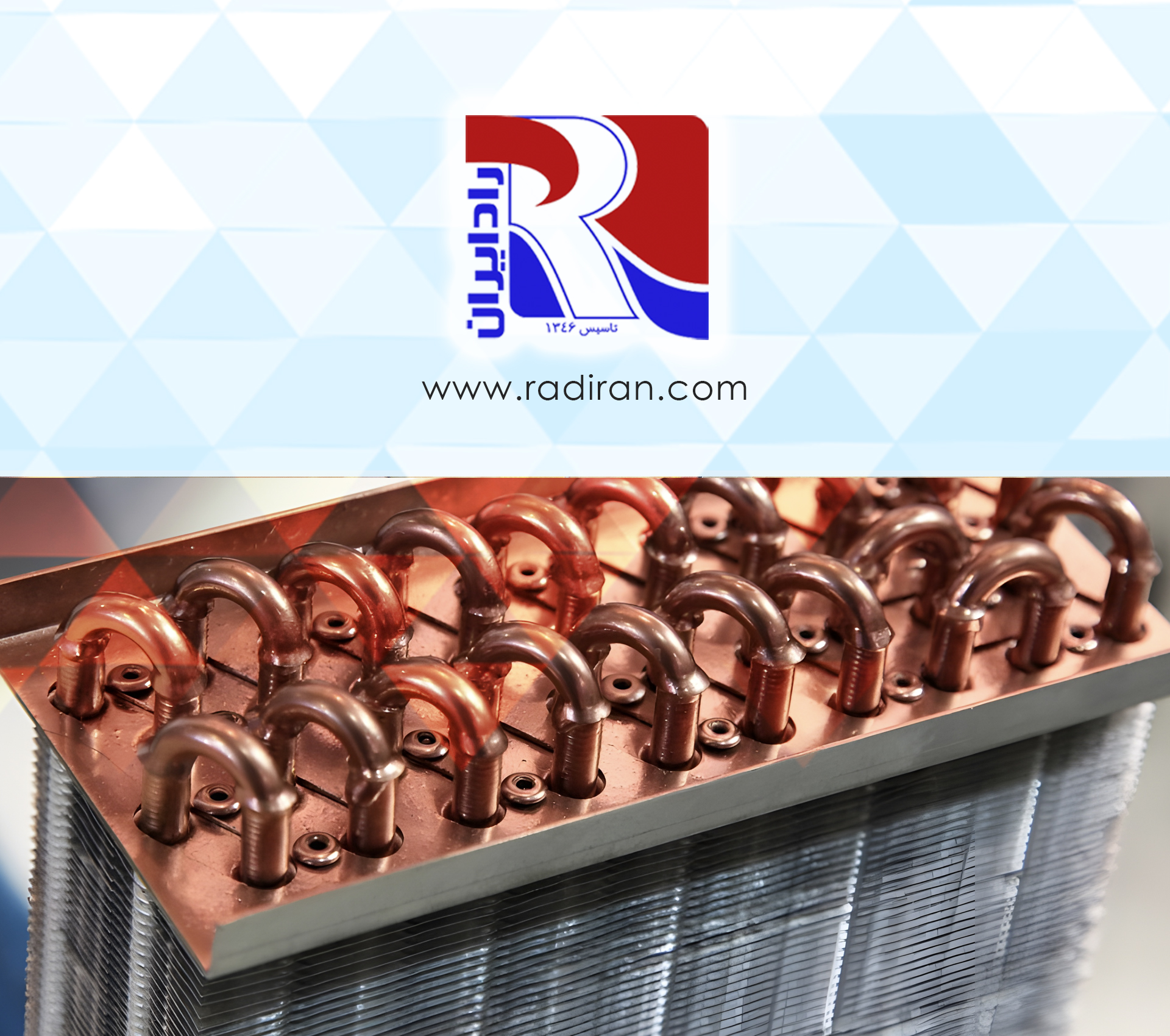

When Is Replacing a Heat Exchanger (Fin Tube Coil) More Cost Effective than Repairing It

Fin tube heat exchangers play a key role in HVAC, heating systems, and industrial processes. Choosing between repair and replacement should be based on technical, economic, and operational analysis. The main criteria are outlined below.

1. Extent and type of failure

• Superficial faults (worn fins, removable fouling, minor joint leaks) can usually be fixed by cleaning, repair, or replacing ancillary parts.

• Widespread damage—such as multiple tube perforations, deep internal corrosion, structural frame failure, or severe fin deformation—indicates irreversible damage and often makes replacement the sensible option.

2. Remaining useful life and overall deterioration

• If the coil is nearing its design life and multiple components are degraded, repeated repairs become costly and undermine reliability. In such cases replacement restores useful life and performance.

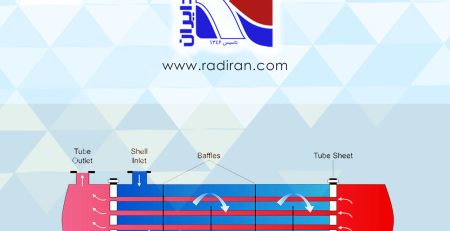

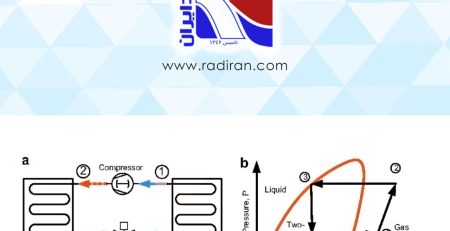

3. Thermal performance and performance degradation

• Significant loss of heat transfer due to deep fouling, altered fin geometry, or internal scaling that cannot be restored by cleaning usually yields much better performance after replacement. Calculate return on investment (ROI) by comparing expected energy savings after replacement with replacement cost.

4. Costs and downtime

• Repair costs include skilled labor, replacement parts, downtime, and the likelihood of follow up repairs. If total repair expense approaches or exceeds the cost of a new coil, replacement is economically preferable. Time required for repair versus replacement is also critical for production sensitive operations.

5. Safety and environmental concerns

• Recurrent fluid leaks or corrosion that risk emissions or contamination should be assessed from a risk perspective. Replacement is often recommended to reduce hazards and ensure regulatory compliance.

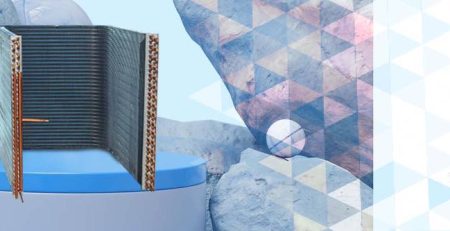

6. Opportunity for upgrade and process compatibility

• If process requirements have changed (higher temperature, different fluid, higher pressure, or increased efficiency demands) and the existing coil cannot be upgraded, replacement allows selection of improved designs (more corrosion resistant materials, optimized fin geometry, protective coatings).

Conclusion

The final decision should be based on a detailed technical assessment, economic calculation (total cost of ownership, ROI), and operational and safety considerations. In short, replacement is more cost effective when: damage or corrosion is extensive; the unit is near the end of its useful life; repair costs approach or exceed replacement cost; expected energy efficiency gains are substantial; or safety/environmental risks are unacceptable.