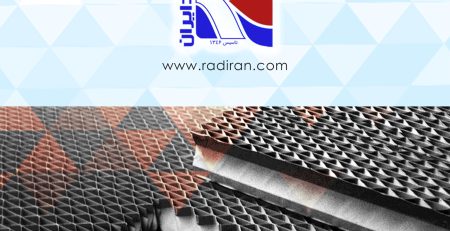

Inline vs. Staggered Tube Arrangement in Fin-and-Tube Coils

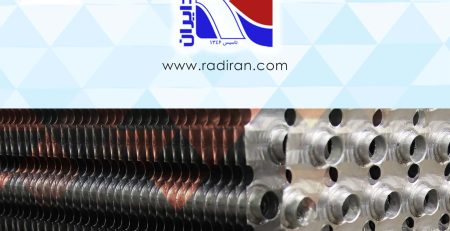

Brief introduction: Fin–tube coils (aluminum fins and copper tubes) are commonly arranged in two tube layouts: inline (linear rows/columns) and staggered (triangular). Each layout affects airflow behavior, heat transfer coefficient, pressure drop, and manufacturing/installation costs.

Inline layout

- Structural features:

o Tubes are placed in regular rows and columns with uniform spacing; the pattern is rectangular/square rather than hexagonal.

- Effects on heat transfer:

- Positives:

- Airflow is more uniform and less turbulent, giving a more predictable velocity distribution and simplifying convection modeling.

- Thinner, more stable boundary layers in some cases, which can be beneficial for predictable heat transfer performance.

- Negatives:

- Less turbulence → lower convective heat transfer coefficient compared with staggered layout; lower surface heat transfer rate (h decreased).

- Larger wake regions and flow separation behind tubes can reduce effective heat exchange uniformity.

- Positives:

- Effects on pressure drop and flow distribution:

- Positives:

- Lower overall pressure drop due to reduced flow resistance; fans operate with lower power.

- Negatives:

- At high velocities, insufficient mixing can reduce effective heat transfer performance.

- Positives:

- Economic effects:

- Positives:

- Typically lower manufacturing and assembly costs because of simpler geometry and easier production.

- Lower operating costs (reduced fan power); easier cleaning and maintenance.

- Negatives:

- To match the heat capacity of a staggered coil, more fin area or additional rows may be required, potentially increasing material and volume costs.

- Positives:

Staggered (triangular) layout

- Structural features:

- Tubes are arranged in a triangular/staggered pattern; transverse spacing is smaller and tube density is higher.

- Effects on heat transfer:

- Positives:

- Increased flow disturbance between tubes → higher convective heat transfer coefficient and improved surface heat transfer (h increased).

- Better utilization of fin area and more uniform heat distribution; higher thermal capacity per unit volume.

- Negatives:

- Increased local flow complexity and temperature non-uniformities can complicate analysis and design.

- Positives:

- Effects on pressure drop and flow distribution:

- Positives:

- Can provide more uniform thermal distribution in some designs.

- Negatives:

- Significantly higher air pressure drop and flow resistance; requires more powerful fans and higher energy consumption.

- More prone to dust accumulation and fouling between tubes, degrading long-term performance.

- Positives:

- Economic effects:

- Positives:

- Higher heat capacity per volume may reduce required footprint, saving space and potentially lowering installation space costs.

- Negatives:

- Higher manufacturing cost due to tighter assembly tolerances and more tube/finned area; increased material usage possible.

- Higher operating costs from stronger fan requirements and increased maintenance/cleaning complexity.

- Positives:

Concise conclusion:

- Choose inline when lower pressure drop, lower manufacturing cost, and easier maintenance are priorities and space is not limited.

- Choose staggered when maximizing heat transfer per unit volume and reducing footprint are priorities and higher fan power and manufacturing/maintenance costs are acceptable.

- Final selection depends on design parameters (air velocity, acceptable pressure drop, space constraints, operating vs. capital costs); optimization typically involves adjusting fin geometry, tube spacing, and layout.