Key Points for Maintaining Chiller Evaporators

1. Installation of Strainer in the Water Inlet to the Chiller Evaporator

Installing a strainer in the water inlet to the chiller evaporator is essential and offers numerous benefits:

• Prevention of Suspended Particle Ingress:

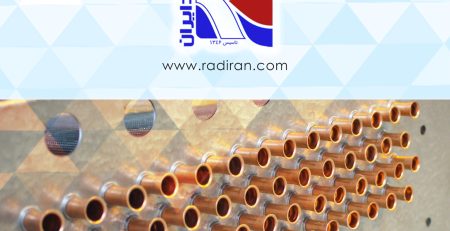

The chiller evaporator, being a sensitive component of the heat exchange system, is susceptible to damage from particles like sand, rust, and debris. These particles can reduce heat transfer efficiency and cause blockages in the system.

• Difficulty in Cleaning After Contamination:

Once contaminants enter, cleaning the evaporator can be challenging and costly since its complex design makes it difficult to access.

• Reduction of Failure Risk:

Strainers help extend the device’s lifespan and decrease the likelihood of failures caused by blockages.

• Regular Maintenance and Cleaning of the Strainer:

Periodic cleaning of the strainer is vital to maintain water flow and prevent pressure drops in the system. Accumulation of particles in the strainer can lead to decreased device performance.

• Choosing the Right Strainer:

The type of strainer should be selected based on the quality and conditions of the incoming water. Strainers with smaller mesh sizes are more suitable for water with finer particles.

• Proper Installation of the Strainer:

The strainer should be placed appropriately in the pipeline, specifically before the water enters the evaporator.

2. Installation of Water Softener in the Water Inlet to the Chiller Evaporator

Water passing through underground aquifers may contain various carbonates and bicarbonates of calcium and magnesium, leading to hard water. Hard water deposits can damage components like packages, radiators, boilers, coil-based resources like fan coils, and the chiller or its pipes.

To mitigate water hardness and prevent deposits, a water softener is necessary. This system filters out the minerals, producing soft and clean water that does not harm pipes or tanks, and is also safe for human consumption.

Conclusion

Key maintenance practices for optimizing the operation of chiller evaporators include the installation of both strainers and water softeners. These measures prevent the ingress of suspended particles and scale build-up, enhancing device longevity and efficiency. Additionally, regular maintenance and cleaning of these systems should be integral to the maintenance program.