Shell and tube condensers

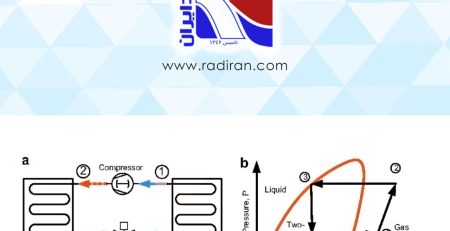

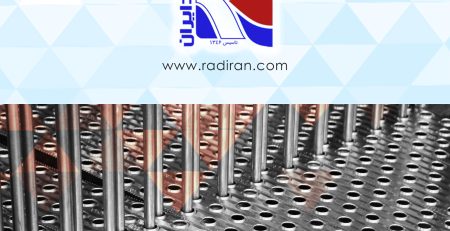

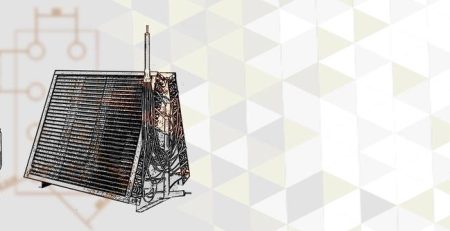

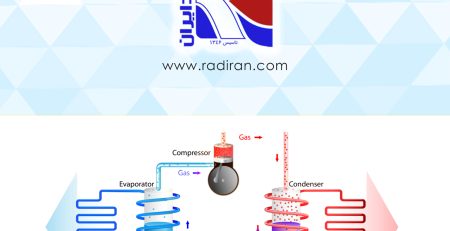

Shell and tube condensers, pivotal components within water-cooled chillers, are masterfully engineered to orchestrate the efficient exchange of heat in the refrigeration cycle. Configured with a cylindrical shell housing a bundle of tubes, these condensers facilitate the intricate dance between the hot refrigerant and circulating water. Crafted from materials with high thermal conductivity, the tubes serve as conduits for the water, while refrigerant flows around them within the shell, creating an optimal environment for heat exchange.

As the hot, high-pressure refrigerant traverses the shell, it relinquishes its thermal energy to the water in tubes. This transformative process induces the refrigerant to undergo a phase change, transitioning from a gaseous state to a liquid. Internal baffles strategically placed within the shell enhance the efficiency of heat transfer by promoting turbulence in the refrigerant flow, optimizing the overall performance of the condenser.

Beyond their efficiency, shell and tube condensers boast a space-efficient design, particularly valuable in chiller units where real estate is limited. However, the quality of circulating water is paramount, as impurities may lead to corrosion or scaling within the tubes, diminishing the condenser’s efficacy. Regular maintenance, including tube cleaning, is imperative to ensure the longevity and sustained performance of these condensers. In conclusion, these unsung heroes of the refrigeration process, with their elegant design and meticulous functionality, contribute significantly to the efficiency and compactness of water-cooled chiller systems, playing a crucial role in maintaining comfortable and cool environments.