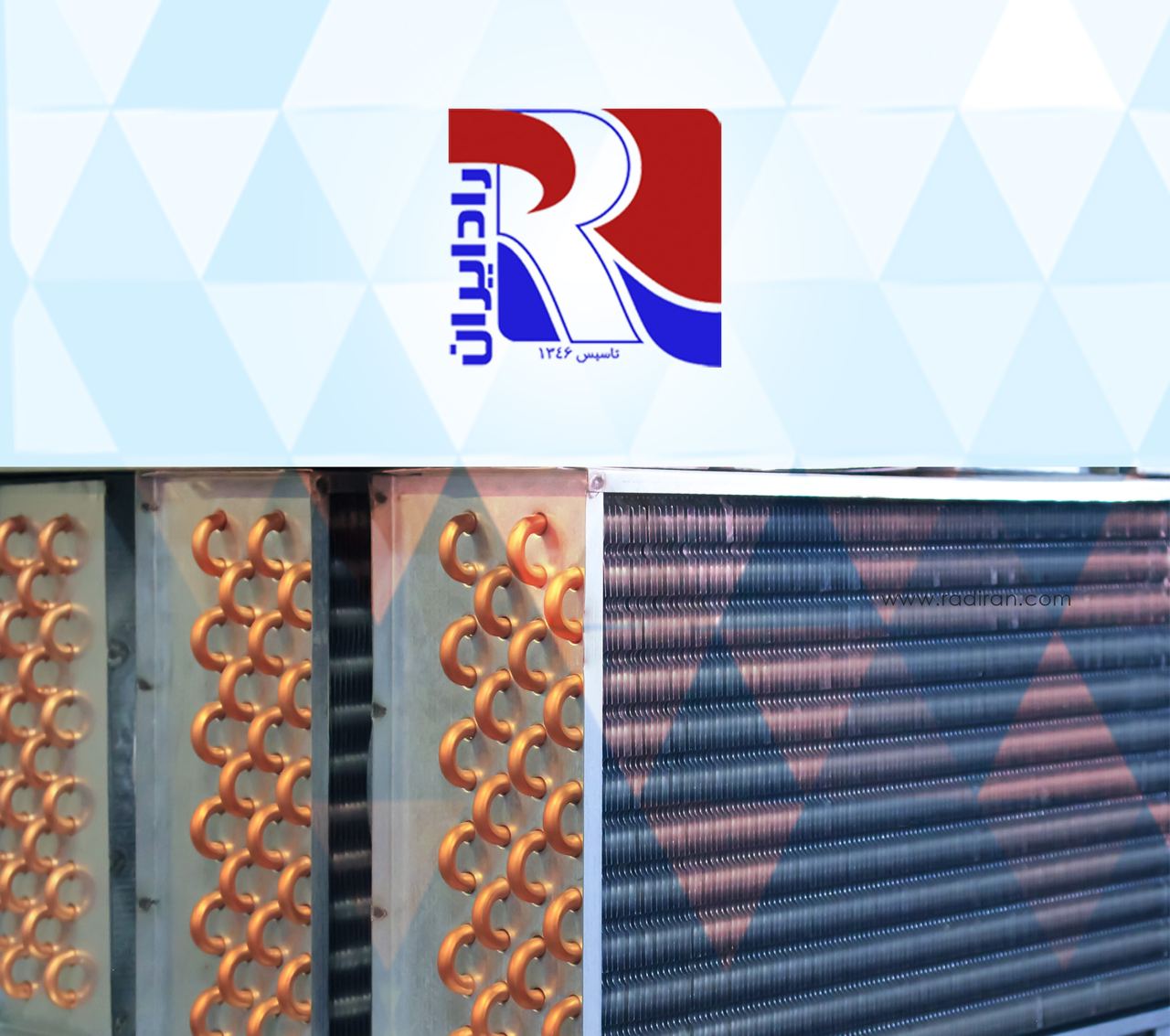

Different types of fin tube Condensers

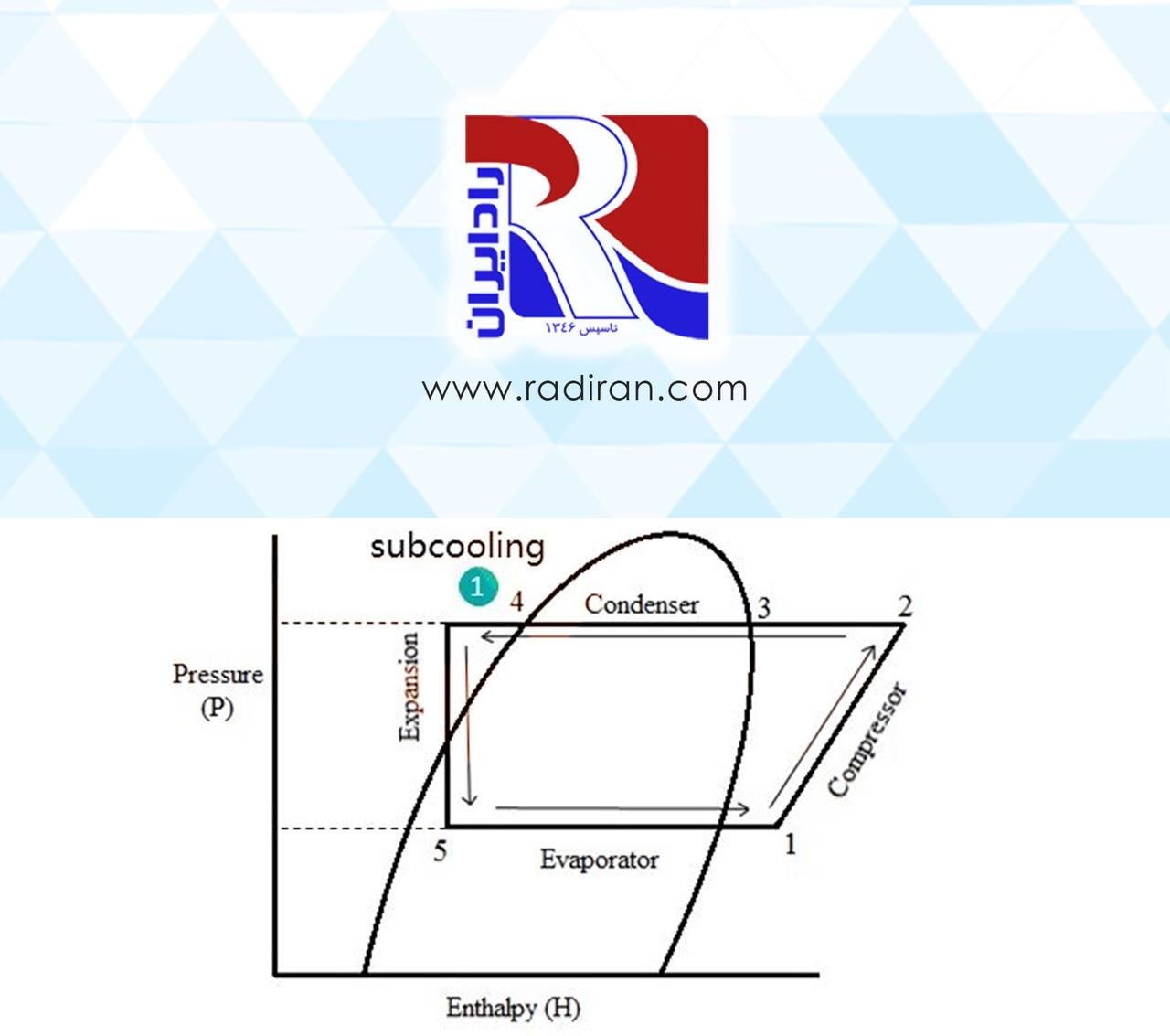

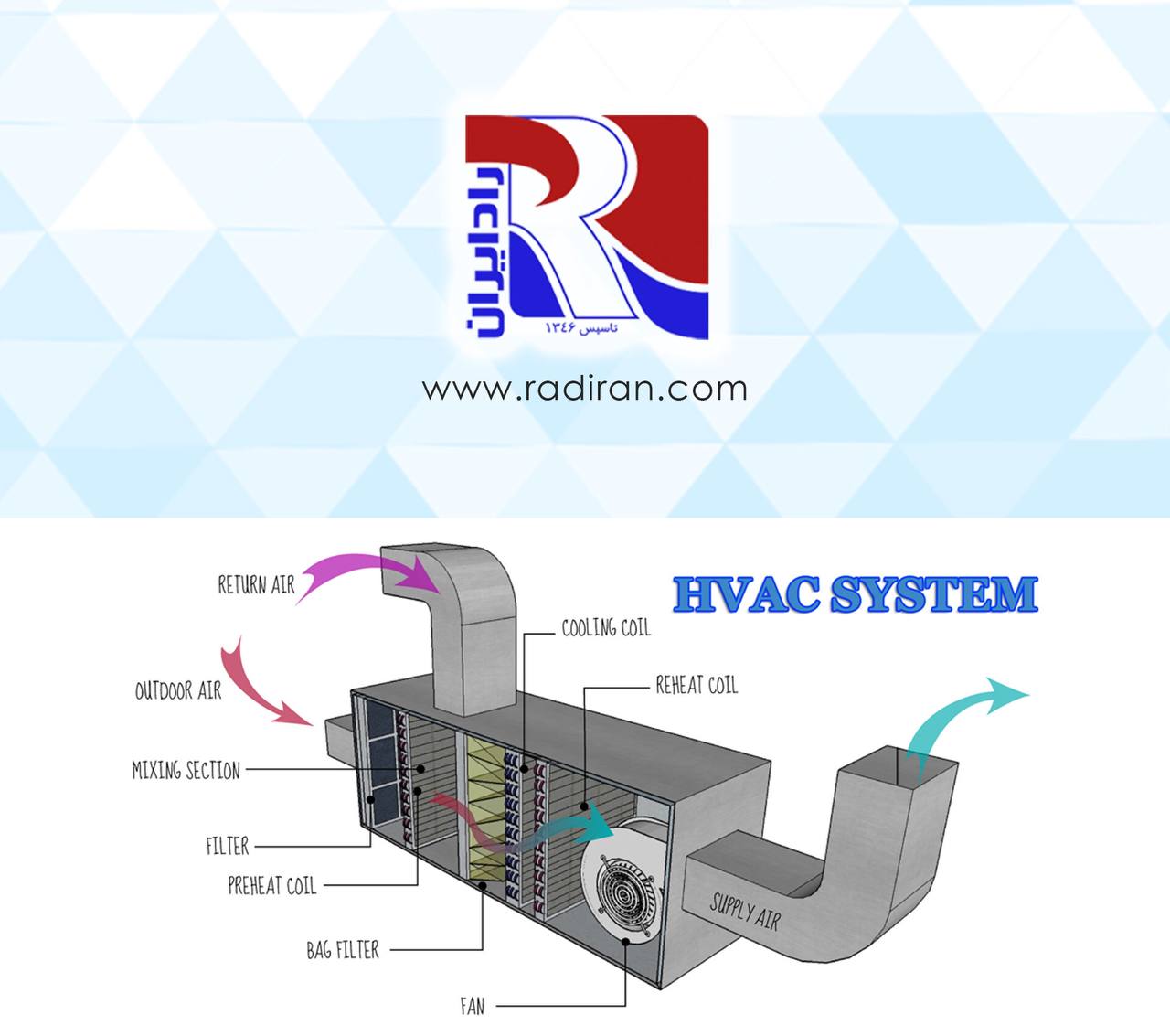

Condensers can be classified based on their configurations and designs. Some common types include: 1. Shell and Tube Condenser: Consists of tubes inside a shell through which the refrigerant flows, exchanging heat with water or air surrounding the tubes. 2. Air-Cooled Condenser: Uses ambient air to cool and condense the refrigerant. Can be further categorized into different configurations like: - Flat Plate Condenser: Horizontal flat plates for heat exchange. - V-Type Condenser: V-shaped configuration for improved airflow. - W-Type Condenser: Multiple V-shapes for enhanced heat...