When Is Replacing a Heat Exchanger (Fin Tube Coil) More Cost Effective than Repairing It

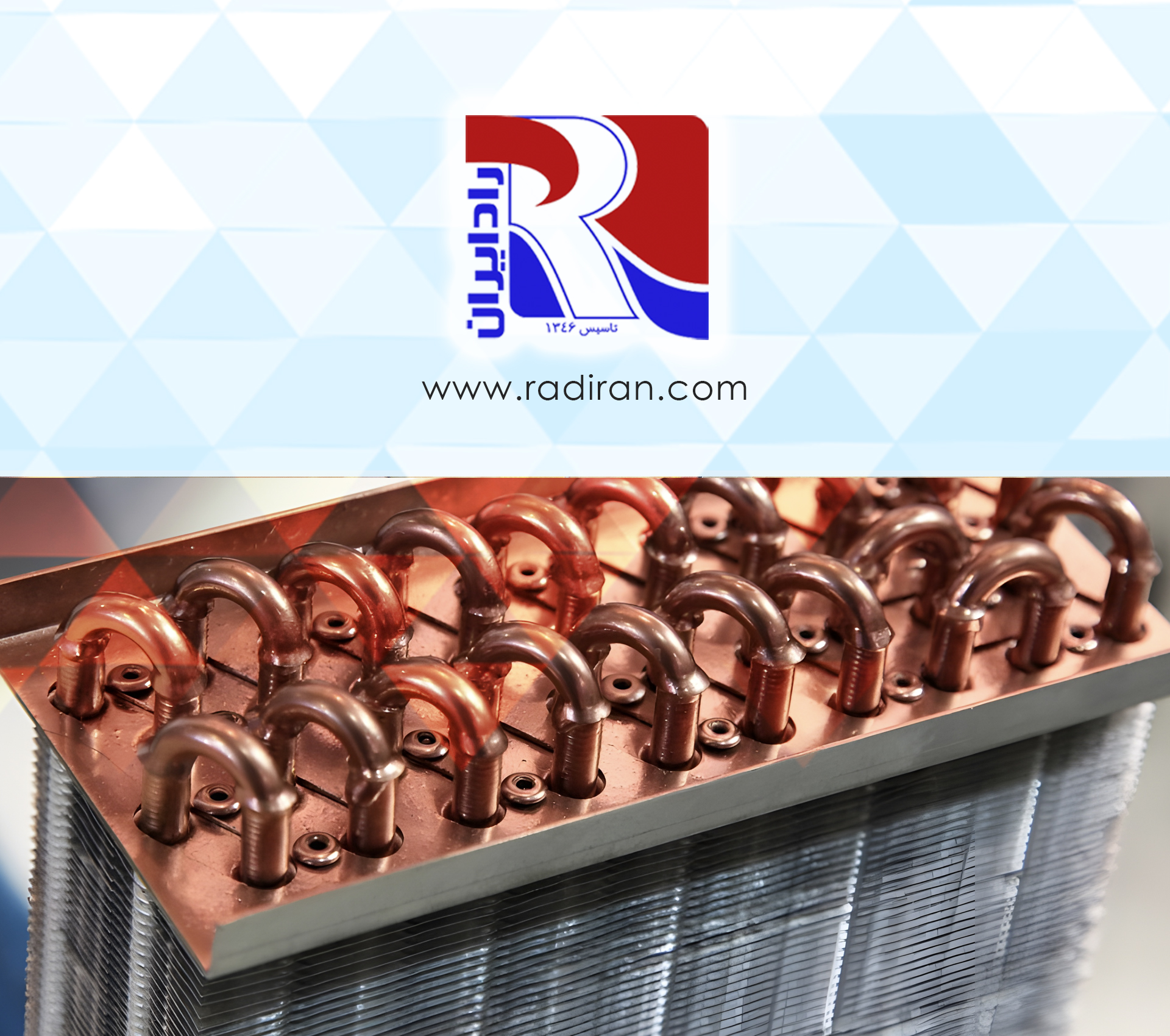

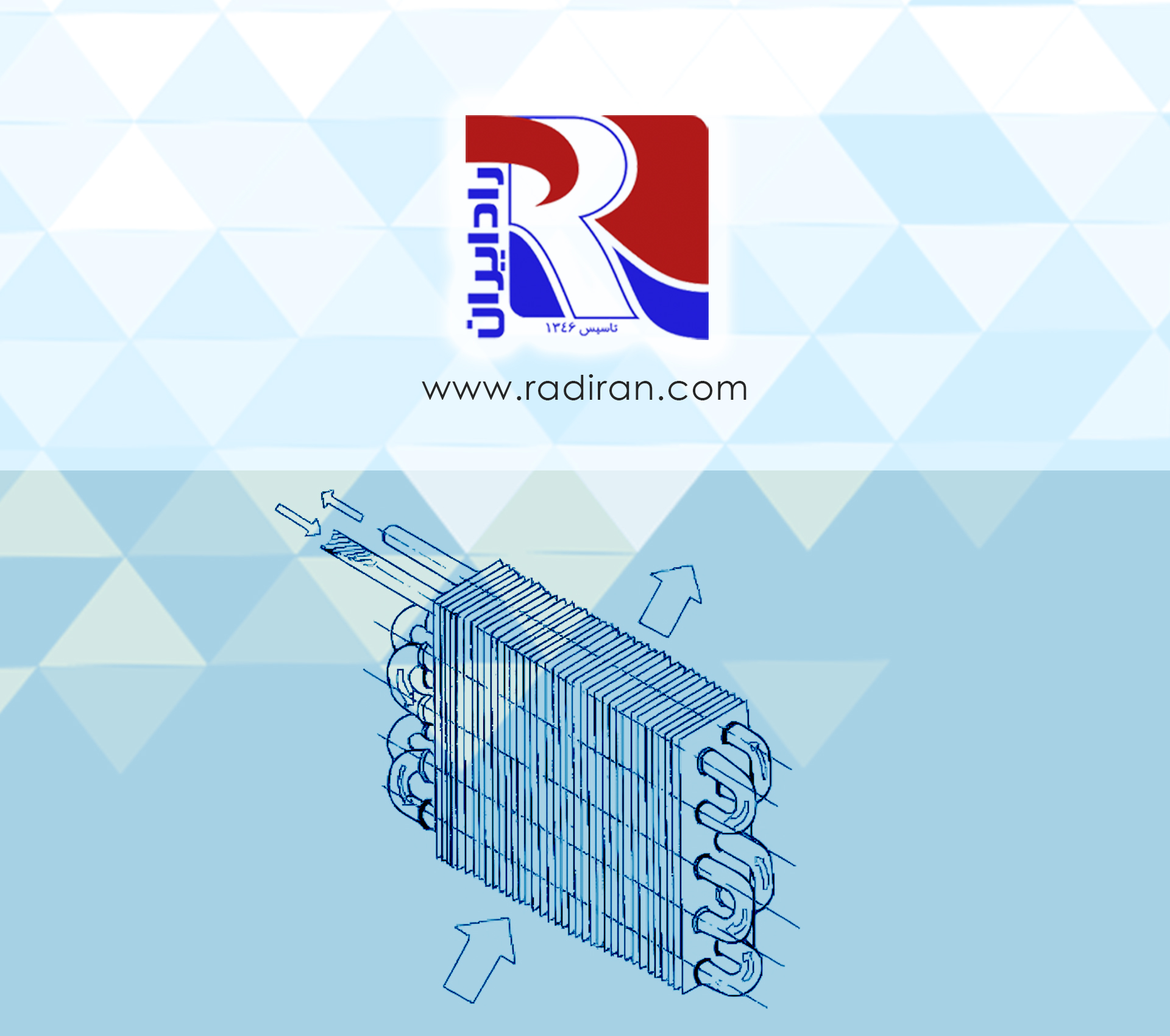

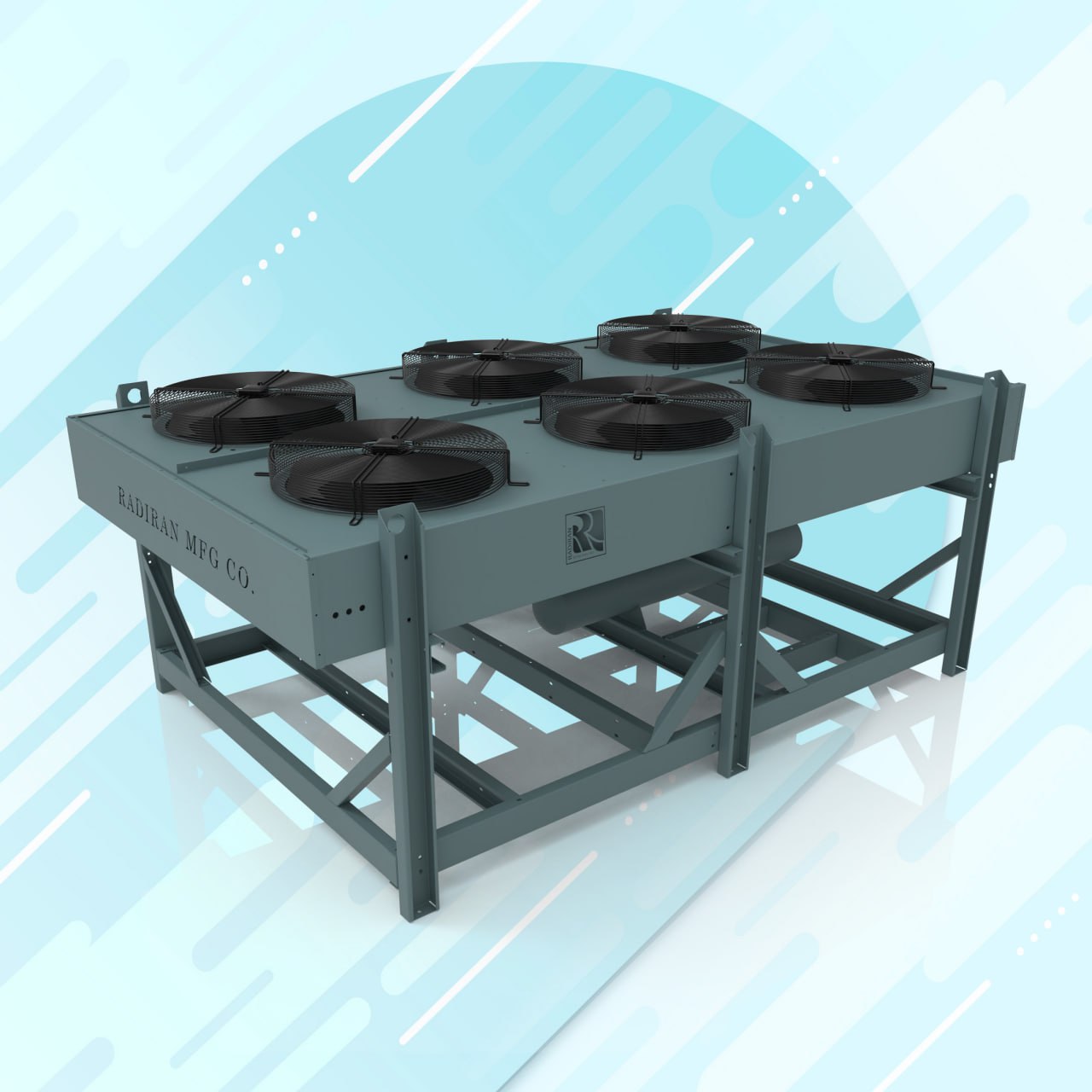

Fin tube heat exchangers play a key role in HVAC, heating systems, and industrial processes. Choosing between repair and replacement should be based on technical, economic, and operational analysis. The main criteria are outlined below. 1. Extent and type of failure • Superficial faults (worn fins, removable fouling, minor joint leaks) can usually be fixed by cleaning, repair, or replacing ancillary parts. • Widespread damage—such as multiple tube perforations, deep internal corrosion, structural frame failure, or severe fin deformation—indicates irreversible damage and often...