Comparative Study Between Two Types of Fin Tube Coils

A detailed and categorized comparative study between two types of fin tube coils (aluminum fin – copper tube) and fin tube coil with aluminum tube, from the perspective of heat transfer, pressure resistance and corrosion resistance, is presented.

- Construction and materials

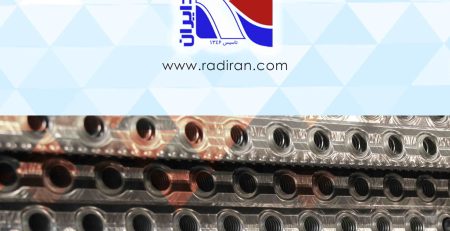

- Coil type A (aluminum fins + copper tubes): Fins are aluminum (common alloys) and tubes are copper (Cu). Fin-to-tube connection is commonly made by mechanically wrapping the fin around the tube, brazing/soldering, or using expanded joints.

- Coil type B (aluminum fins + aluminum tubes): Both fins and tubes are aluminum (often similar or different alloys); connections are usually welded, brazed, or mechanically formed.

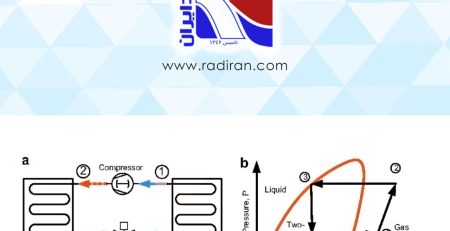

- Heat transfer

- Thermal conductivity of materials: Copper has much higher thermal conductivity (~380–400 W/m·K for pure copper) than aluminum (~205–240 W/m·K). Therefore copper tubes transfer heat from the fluid to the tube outer surface faster.

- Surface and contact thermal resistance: In type A, the aluminum fin-to-copper tube contact may introduce some contact resistance depending on the joining method; nevertheless, because copper is a better conductor, overall heat-transfer performance is usually superior. In type B, having both fin and tube made from aluminum gives uniform contact without metal mismatch, but aluminum’s lower conductivity limits performance. In practice, copper-tube coils typically outperform aluminum-tube coils, especially when tube wall thickness and internal convection coefficients are similar.

- Pressure resistance and mechanical strength

- Copper: Good ductility and formability; copper resists internal pressure well and can achieve similar pressure ratings with thinner walls. Long-term creep can occur under sustained high temperature/stress but overall copper tubes offer reliable pressure performance. Copper is easy to join by brazing and soldering.

- Aluminum: Lighter and in some alloys lower strength than copper; to reach the same pressure rating it may require thicker walls or strengthened alloys. Aluminum can be less tolerant to impact and bending and may be more prone to cracking under certain conditions.

- Corrosion and durability

- Copper: Good resistance to general corrosion in many freshwater and HVAC conditions, but susceptible to pitting or dealloying in the presence of chlorides, ammonia, or sulfides; under aggressive water chemistry it can suffer localized attack. Fouling and biological deposits are possible. Protective coatings or water-chemistry control can mitigate risks.

- Aluminum: Forms a passive oxide layer which protects the surface in many environments, but is vulnerable to pitting in chloride-containing or strongly alkaline conditions. When aluminum tubes are used with copper fins (type A) there is a risk of galvanic corrosion at the Al–Cu junction unless electrically insulated or otherwise protected.

- Summary — why copper tubes are generally better

- Higher thermal conductivity of copper → better heat-transfer performance and potentially smaller heat-exchange surface area.

- Good pressure-bearing capability and mechanical performance with thinner walls → more compact designs.

- Adequate corrosion resistance in many service conditions, though attention is needed in aggressive chemistries.

Therefore, fin-and-tube coils with copper tubes and aluminum fins are typically superior in thermal performance and mechanical behavior. Final selection should consider fluid chemistry, external environment, cost, manufacturability, and maintenance requirements.