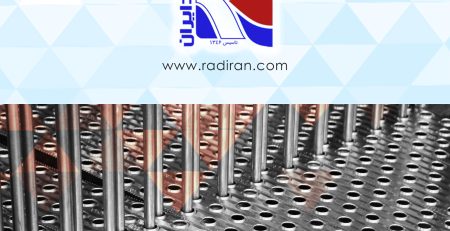

Comparison of mechanical pressure resistance in 5/8 inch tubes with wall thicknesses of 0.5, 0.63, and 1.0 mm

Introduction:

This study briefly examines the mechanical and thermal behavior of copper tubes (5/8 in. size) with three different wall thicknesses (0.5 mm, 0.63 mm and 1.0 mm) in fin-tube coils. The goal is to determine approximate allowable pressure and temperature ranges and to explain performance differences resulting from wall-thickness variation.

Material properties and assumptions:

- Material: commercial copper (e.g., C110) with ultimate tensile strength around 200–250 MPa and typical yield/working strength ~220 MPa, Young’s modulus ≈ 110 GPa.

- Outer tube diameter 5/8 in ≈ 15.875 mm.

- Typical fin-tube coil operating conditions: heat transfer between refrigerant/water inside the tube and air outside; operating temperatures commonly range from about −40 °C to ~150 °C depending on refrigerant/application.

- Design approach: use thin-wall cylinder approximations and apply a safety factor of about 2–3 for allowable working stress.

Pressure capacity (approximate):

- Using the thin-wall hoop-stress relation for internal pressure:

σ_hoop = (p·r)/t → rearranged for allowable internal pressure p_allow ≈ (σ_allow·t)/r,

where r = D_o/2 ≈ 7.9375 mm. - Assume an operational allowable stress σ_allow ≈ 100 MPa (rough approximation after applying a safety factor of 2 to material strength):

- t = 0.5 mm: p_allow ≈ (100×10^6·0.0005)/0.0079375 ≈ 6.3 MPa ≈ 63 bar.

- t = 0.63 mm: p_allow ≈ (100×10^6·0.00063)/0.0079375 ≈ 7.94 MPa ≈ 79 bar.

- t = 1.0 mm: p_allow ≈ (100×10^6·0.001)/0.0079375 ≈ 12.6 MPa ≈ 126 bar.

- Conclusion: thicker-walled tubes can carry significantly higher internal pressures. In practice, manufacturing standards, fittings, joints, and the chosen safety factors will reduce allowable working pressure; typical fin-tube products are usually designed for working pressures of several tens of bar.

Temperature tolerance:

- Copper has high thermal conductivity and retains adequate mechanical strength over a wide temperature range. Mechanical properties degrade with increasing temperature; up to roughly 200–300 °C copper still performs reasonably, but yield strength decreases.

- At low temperatures (down to about −40 °C) copper does not become markedly brittle like some steels, so behavior remains acceptable.

- For common HVAC and chiller applications: safe operating fluid temperatures inside the tube are approximately −40 to +120 °C. For higher temperatures, additional checks for oxidation/corrosion, creep, and altered mechanical properties are required.

Conclusion:

For a 5/8 in copper tube, increasing wall thickness from 0.5 mm to 0.63 mm and to 1.0 mm yields a substantial increase in estimated internal pressure capacity — roughly from 63 bar to 79 bar and 126 bar respectively (theoretical estimates using a conservative allowable stress). Regarding temperature, all three thicknesses are suitable for typical HVAC operating ranges (about −40 to +120 °C), but for very high temperatures or corrosive environments further analysis and adherence to relevant codes and standards (e.g., ASME, EN standards, HVAC industry specifications) are necessary. For final design, perform detailed calculations using the exact material properties, the selected safety factor, and account for joints, fittings and fatigue/cycling conditions.