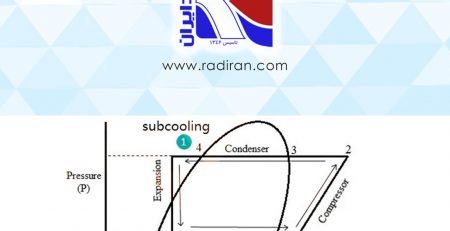

Optimization of Aluminum Fin Geometry for Enhancing Cooling Efficiency in Copper Tube Coils

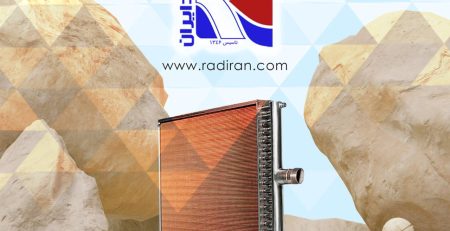

Finned coils composed of aluminum fins and copper tubes are among the most effective and widely used heat transfer systems in HVAC, refrigeration, and industrial heating and cooling applications. In these coils, the high thermal conductivity of copper tubes carrying the cooling or heating fluid combines with the adequate thermal conduction properties of aluminum fins to provide an optimal balance of heat transfer efficiency and corrosion resistance. A critical factor in improving the overall performance of these coils is the geometric design of the fins, which plays a vital role in increasing heat transfer area and regulating airflow.

Importance of Fin Geometry Design

Aluminum fins increase the heat exchange surface area between the fluid inside the copper tubes and the surrounding air, thus enhancing the total efficiency of the coil. However, selecting the optimal fin dimensions requires a careful balance between thermal conduction, air pressure drop, and mechanical strength. Increasing fin density or reducing the spacing between fins can raise the heat transfer area but may also lead to higher airflow resistance, which negatively impacts energy consumption and fan performance.

Influential Parameters in Fin Design

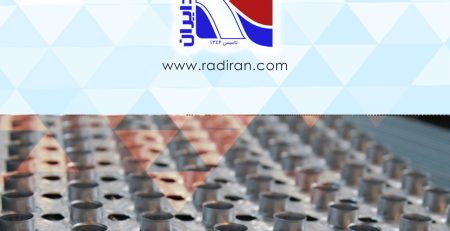

Fin dimensions such as thickness, height, length, and pitch (the distance between fins) are critical parameters. Excessive thickness increases thermal resistance, reducing heat transfer efficiency, whereas too thin fins may lack sufficient mechanical strength, making them prone to environmental damage. Fin height should be designed to optimize airflow and ensure uniform temperature distribution throughout the coil.

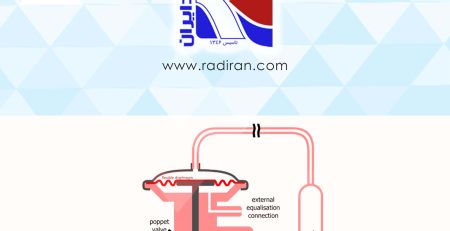

Role of Fin Shape

The shape of the fins significantly affects heat transfer and airflow dynamics. Flat, wavy, or perforated fins each come with unique advantages and disadvantages. Wavy fins enhance airflow turbulence, improving heat transfer rates but potentially increasing pressure drop. Perforated fins help prevent dust accumulation but may reduce the effective heat transfer area.

Effect of Aluminum Fin Material

Aluminum, being a lightweight metal with high thermal conductivity and good corrosion resistance, is ideal for fins. Selecting appropriate aluminum alloys (such as series 1000 or 3000) and applying surface treatments like anodizing or anti-corrosion coatings can enhance both coil lifespan and thermal performance depending on operational environments.

Impact of Environmental Conditions

Environmental factors such as humidity, temperature, and airborne contaminants significantly influence fin performance. For example, in humid or industrial environments, corrosion and deposit buildup on fins can diminish heat transfer capacity. Proper geometric design can facilitate consistent, clean airflow and reduce particle accumulation.

Conclusion and Optimization Strategies

Optimizing the geometry of aluminum fins in copper tube coils requires detailed analysis of dimensional and shape-related parameters. Employing computational fluid dynamics (CFD) and heat transfer simulations to evaluate various design combinations is an effective approach. Additionally, using suitable aluminum alloys, applying protective coatings, and considering environmental conditions contribute to enhanced coil efficiency and longevity. Ultimately, achieving a balanced design that maximizes heat transfer area while minimizing airflow resistance is the key to optimizing cooling performance.