Units of flow rate in HVAC

In the HVAC (Heating, Ventilation, and Air Conditioning) industry, accurately measuring airflow is critical for designing and maintaining efficient systems. Several units are used to quantify airflow rates, with CFM (Cubic Feet per Minute) and cubic meters per hour (m³/h) being among the most common.

CFM

CFM, or Cubic Feet per Minute, is a widely used unit in the HVAC industry in the United States and other countries that follow imperial measurement systems. It represents the volume of air being moved per minute. For instance, if an HVAC system is rated at 400 CFM, it means the system can move 400 cubic feet of air every minute. This measurement is crucial for determining the capacity of an HVAC system to ventilate a space, ensuring proper air circulation and maintaining indoor air quality.

M³/h

On the other hand, cubic meters per hour (m³/h) is a metric unit commonly used in regions that follow the International System of Units (SI), such as Europe. It indicates the volume of air transported per hour. For example, an HVAC system with a flow rate of 1000 m³/h moves 1000 cubic meters of air each hour. Converting between CFM and m³/h is straightforward: 1 CFM is approximately equal to 1.7 m³/h.

Other units used in the HVAC industry include liters per second (L/s) and cubic meters per second (m³/s). Liters per second is particularly useful for smaller-scale applications or precise measurements, where 1 L/s equals 3.6 m³/h. Meanwhile, cubic meters per second is used for very large systems, with 1 m³/s equating to 3600 m³/h.

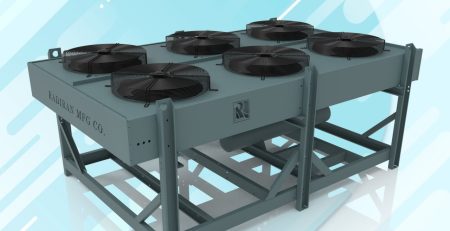

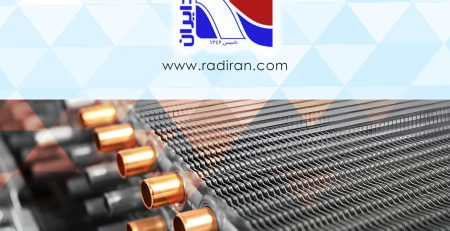

These airflow measurements are crucial in designing HVAC systems to ensure they meet the specific needs of a building. Proper airflow ensures adequate ventilation, maintains indoor air quality, and provides the necessary heating or cooling to keep indoor environments comfortable. Understanding and accurately measuring airflow in CFM, m³/h, and other units is essential for the efficiency, performance, and comfort provided by HVAC systems. In Radiran, Engineers and HVAC professionals rely on these units to design and manufacture different types of coils, select appropriate fans and blowers, and ensure compliance with building codes and standards.