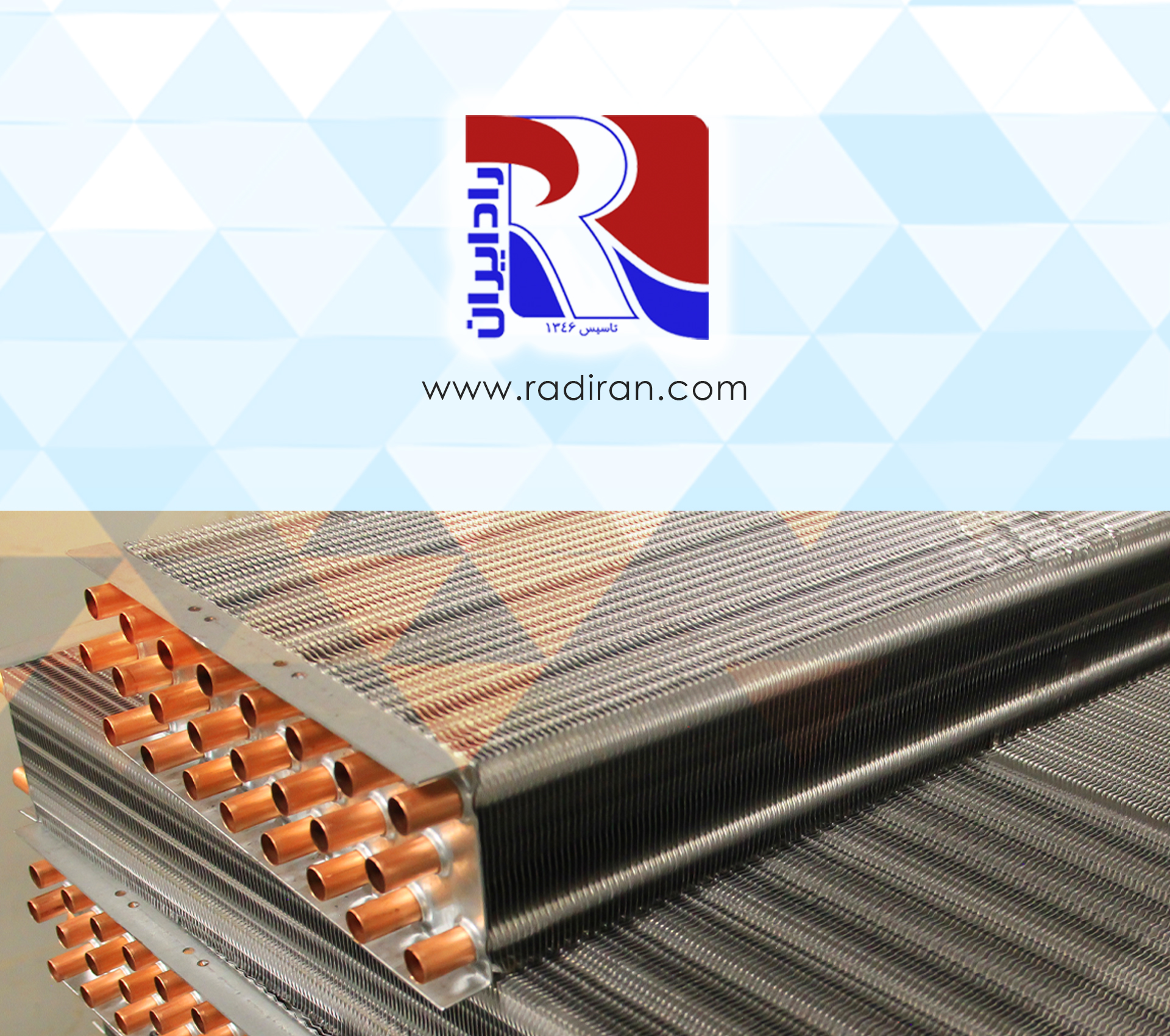

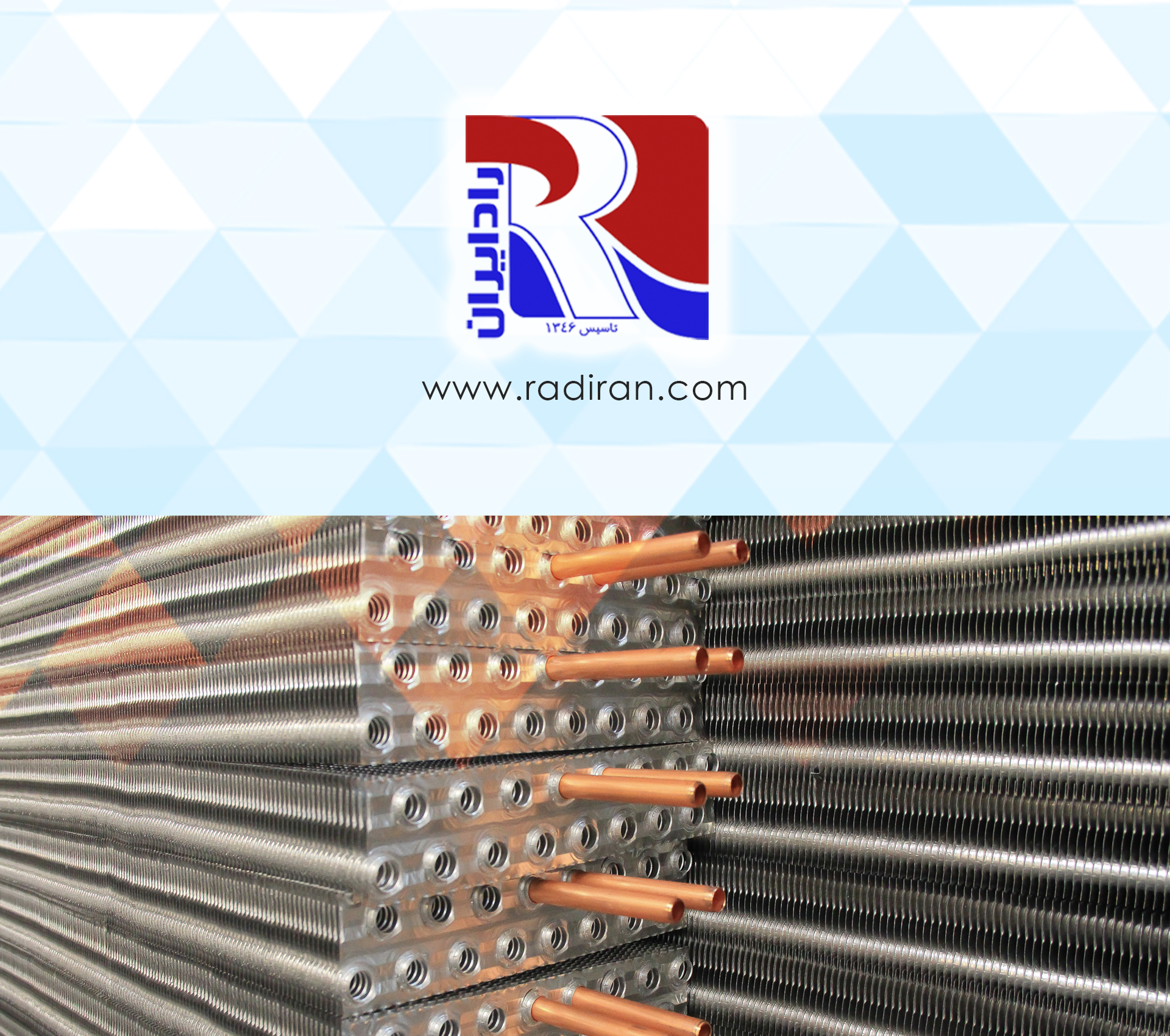

The engineering comparison of 5/8″ copper tubes with wall thicknesses 0.50 mm, 0.63 mm and 0.70 mm used in a water coil (fin-tube) with aluminum fins

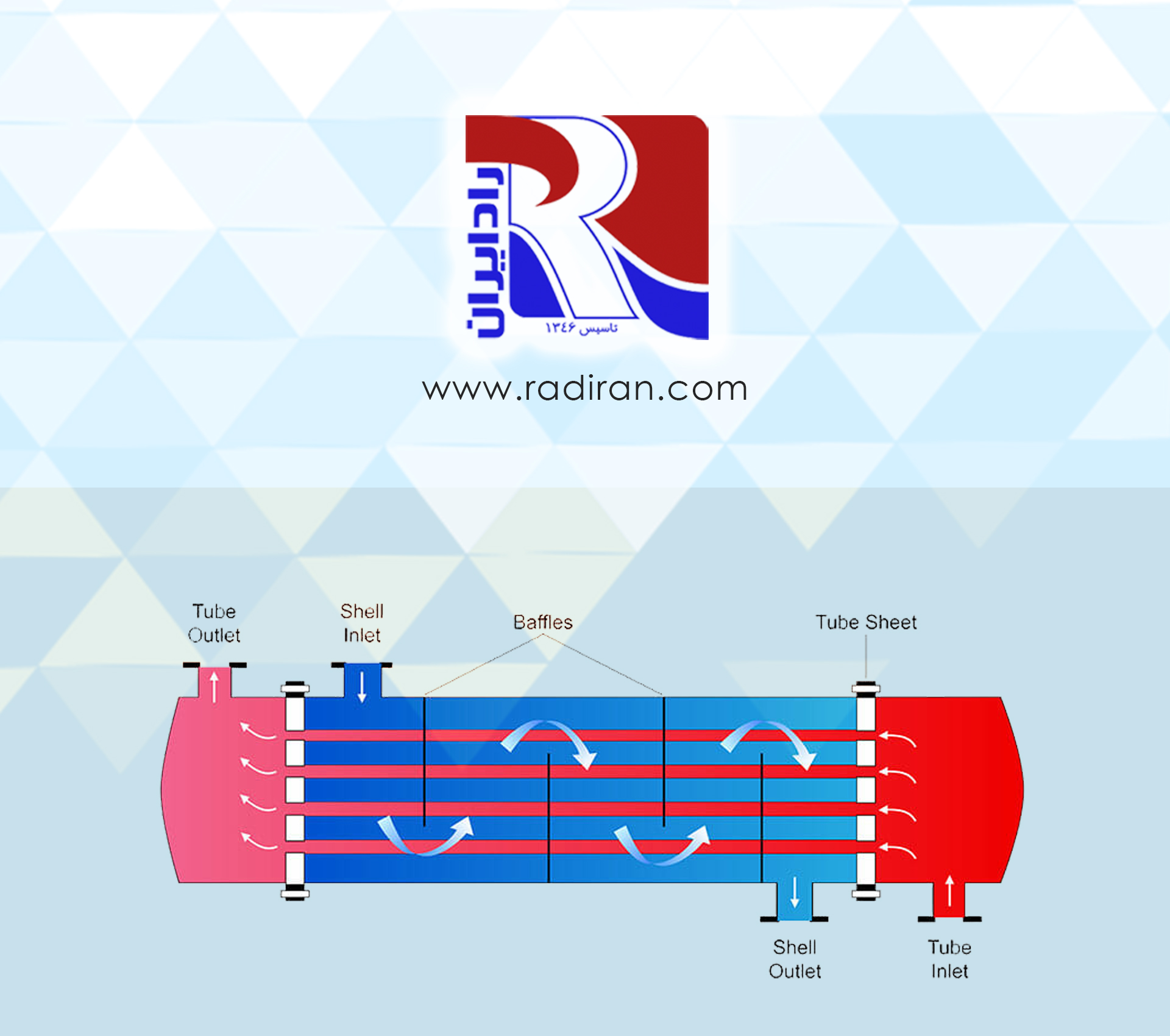

Below is the engineering comparison of 5/8" copper tubes with wall thicknesses 0.50 mm, 0.63 mm and 0.70 mm used in a water coil (fin-tube) with aluminum fins. Internal heat transfer (controlled by conduction and convective heat-transfer coefficient) Internal convective heat-transfer coefficient (hi): for the same volumetric flow rate, thinner-wall tubes (0.50 mm) have a slightly larger internal radius and therefore slightly lower pressure drop and a similar or slightly higher hi compared with thicker tubes. Changes are usually small and mainly...